January 2016

Oilfield Technology |

71

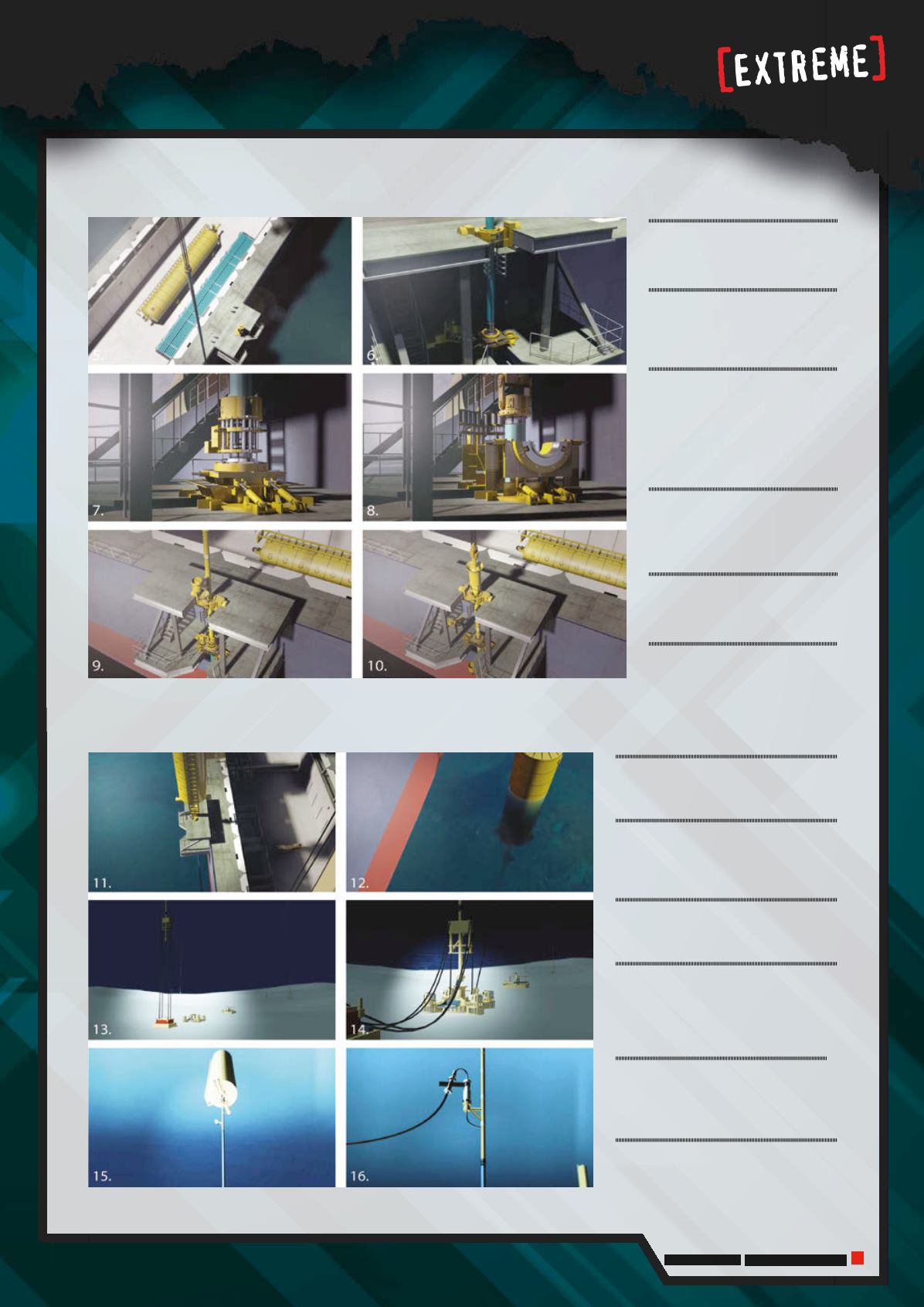

5.

Pipe section is upendedand

alignedwith the riser in the spider.

6.

Upper riser guide is used to align

the pipe segments to the hung off

risers.

7.

Connector assembly tool is

used to lock the pipe segment to

the hung-off riser. Spider table is

openedand riser is loweredand

hung-off.

8.

Additional pipe segments are

added to buildup the length of the

riser.

9.

Top riser assembly is upended

and connected to the hung-off riser.

10.

Riser is hung-off just below the

rotating latch receptacle.

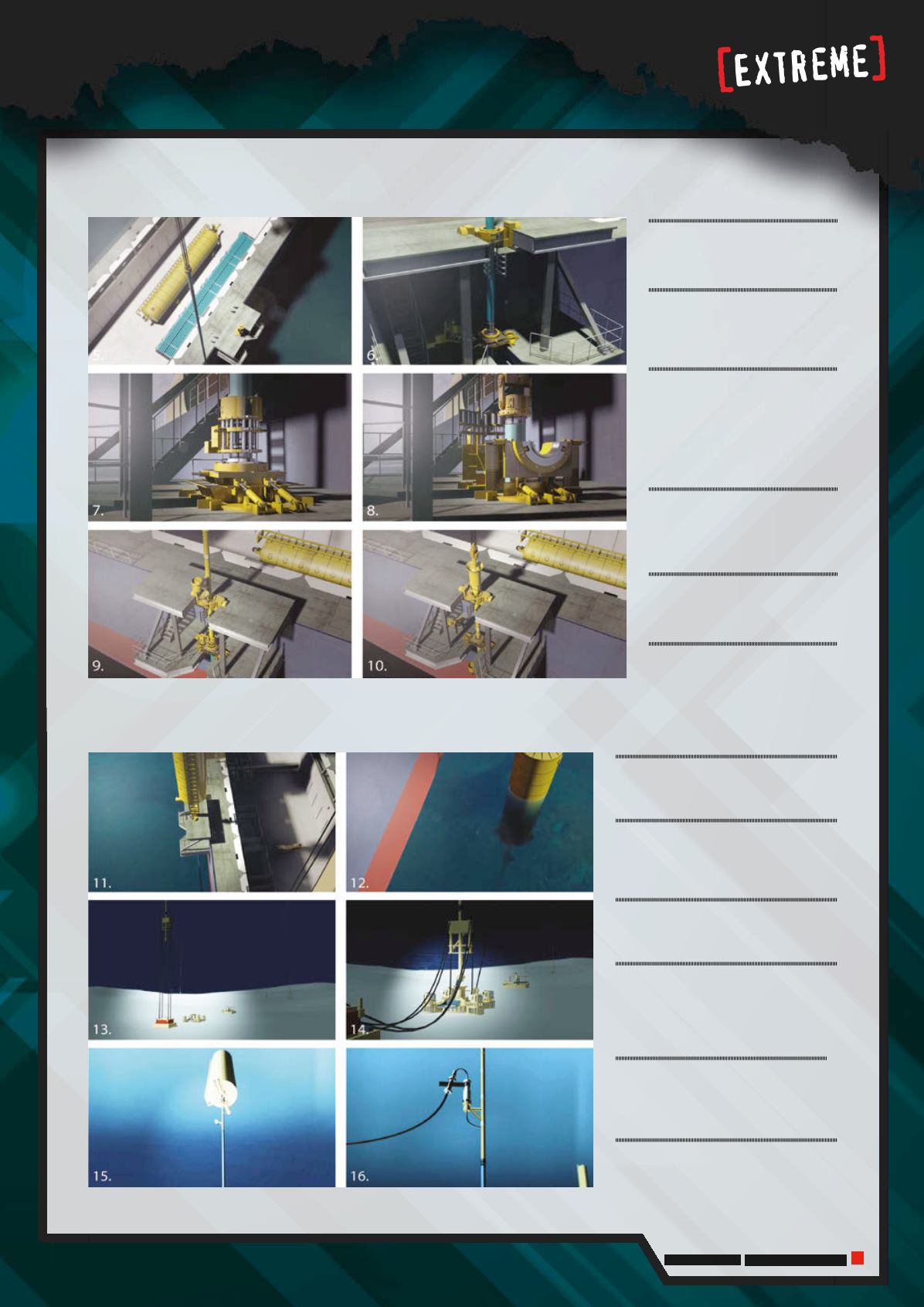

11.

Buoyancy canwith rotating latch is

upendedand connected to the riser.

12.

Buoyancy can is floodedand

the crane is used to lower the riser to

operatingdepth.

13.

Clumpweight is placed on temporary

subsea foundation.

14.

Bottomrider assembly is pulled

down to engage to the rotating latch

to the receptable on the suction can

formation.

15.

Buoyancy can is ventedand crane

wire is released. Heavy lift vessel is

demobilised.

16.

Construction vessel installs flexible

jumper between riser andproduction

facility.