WORLD NEWS

June

2016

HYDROCARBON

ENGINEERING

5

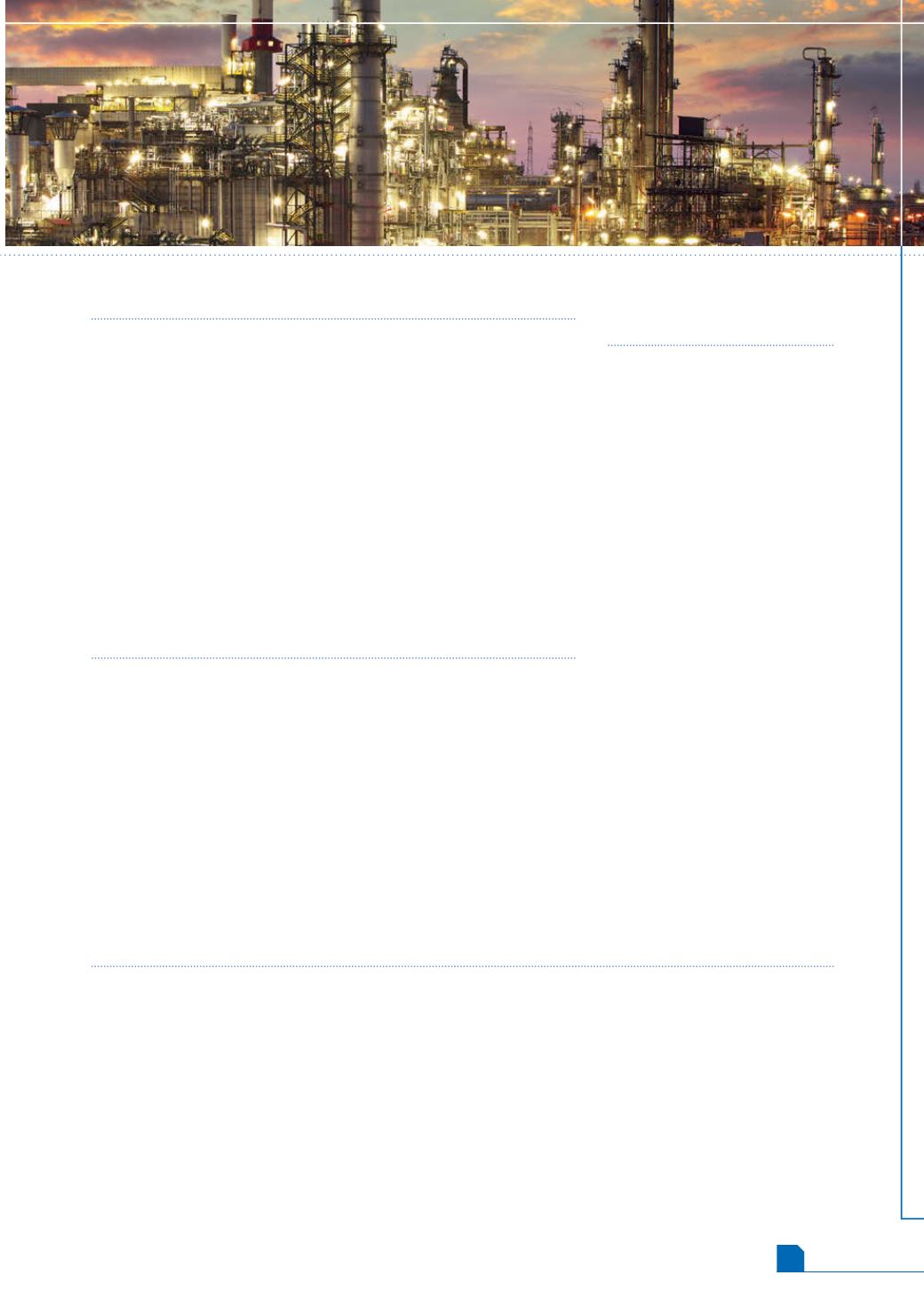

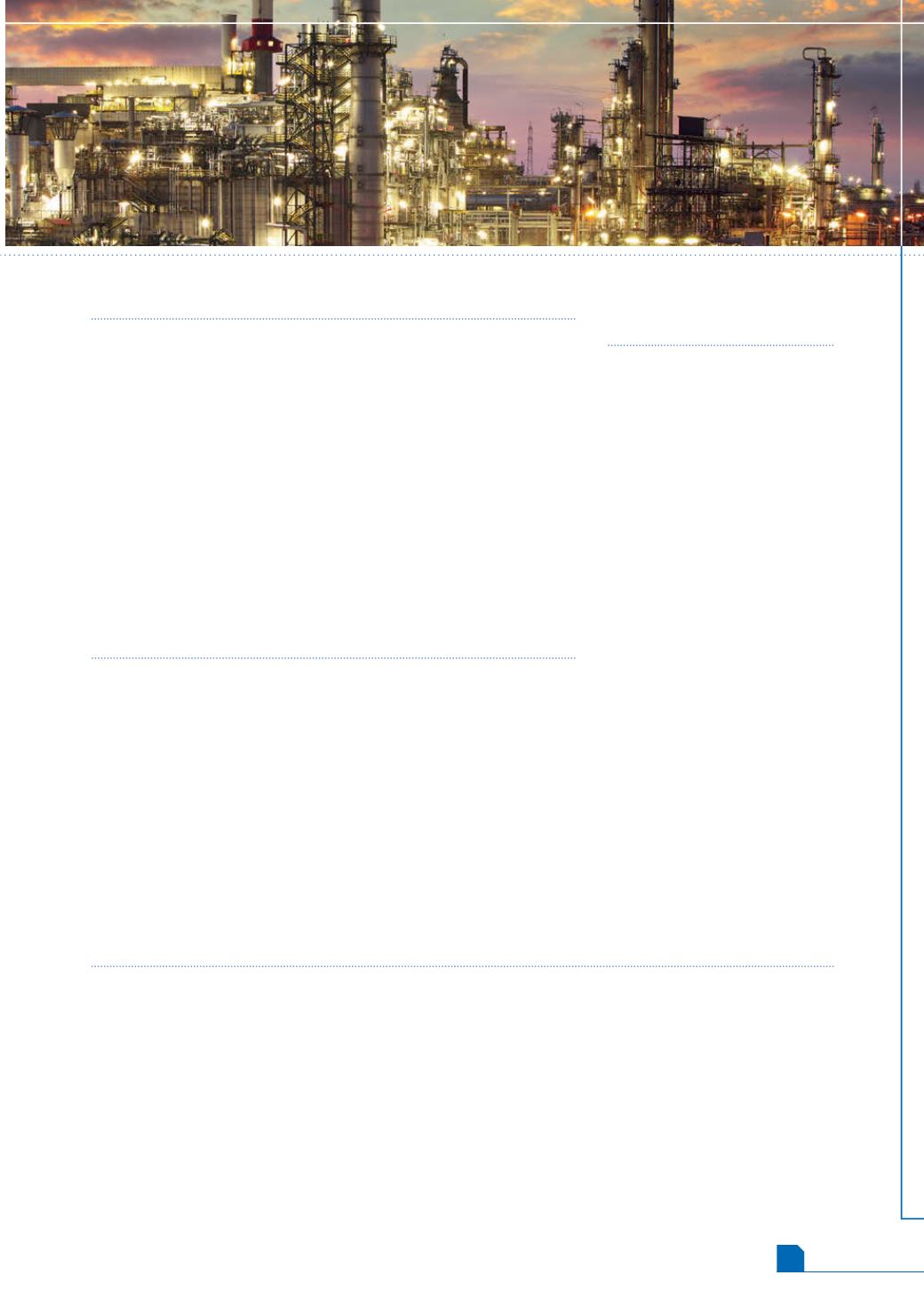

Saudi Arabia |

Engineering services contract

J

acobs Engineering Group, Inc. has

received a two year contract

from Saudi Aramco Total Refining

and Petrochemical Company

(SATORP) to provide general

engineering services (GES) at

SATORP’s Jubail Industrial City II

facilities in Saudi Arabia.

Under the terms of the contract,

Jacobs is providing a range of

feasibility studies, concept design

and detailed engineering design

services for a portfolio of minor

capital expenditure projects.

The contract expands Jacob's

presence in the Jubail Industrial City,

and reinforces its commitment to

providing services to the company's

clients across the region. Jacob's

extensive experience in the provision

of similar services in Saudi Arabia

and its recently established local

presence in Al Jubail were key

factors in helping the company

secure the contract.

SATORP’s 400 000 bpd Jubail

refinery is one of the most advanced

refineries in the world, producing a

wide variety of white products from

heavy crude oil.

USA |

Ultra low sulfur

diesel project

A

llied Energy has selected DuPont™

IsoTherming® hydroprocessing

technology for its ultra low diesel

(ULSD) project at its Transmix

Processing Facility in Birmingham,

Alabama. Development of the

technology began in July 2015, with

project startup anticipated by

August 2016.

IsoTherming is suitable for a wide

range of applications, including

kerosene, diesel and FCC feed

hydrotreating, mild hydrocracking and

heavy oil upgrading for both

grassroots and revamp configurations,

among others. Licensed unit capacities

range from 1500 to 80 000 bpd,

processing feedstocks such as 100%

kerosene, 100% light cycle oil (LCO)

and various mixtures of distillates and

heavy gas oils, including coker blends.

Growing global demand for

transportation fuel continues to drive

refiners toward operations that

maximise hydroprocessing capacity

and capability either through unit

debottlenecks or new unit

construction. IsoTherming technology

offers the refiner lower capital and

operating costs while significantly

reducing sulfur content in motor fuels.

China |

Isobutylene process unit performance

H

oneywell has announced that

Shandong Luqing Petrochemical

Co., an independent integrated

refiner that produces gasoline,

liquefied petroleum gas and

methyl tertiary butyl ether (MTBE),

accepted the performance of

China’s first standalone Honeywell

UOP C

4

Oleflex

TM

process unit,

producing 170 000 tpy of

isobutylene. The unit, located in

Shandong Province on China’s East

Coast, will support the growing

demand for fuel and petrochemicals

in China’s industrial sector.

In addition to licensing,

Honeywell UOP provided the

engineering design, catalysts,

adsorbents, specialty equipment, staff

training and technical service for the

project. The C

4

Oleflex process uses

catalytic dehydrogenation to convert

isobutane to isobutylene, the primary

ingredient for making high octane fuel

and synthetic rubber used in tires,

healthcare supplies and other

consumer products.

The technology delivers superior

performance due to its reliability,

low energy usage, high isobutylene

yields, and a fully recyclable

platinum alumina-based catalyst

system using proven continuous

catalyst regeneration (CCR)

technology.

While Shandong Luqing is the

first Chinese operator of a

standalone Honeywell UOP C

4

Oleflex process, the technology now

has seven customers in the country

with three of them anticipated to

start up by the end of 2016.

Egypt |

Delayed coking technology

B

echtel has signed a license

agreement with Assiut Oil

Refining Company (ASORC), a

subsidiary of Egyptian General

Petroleum Corporation (EGPC), for

the process design of a delayed

coking unit at the Assiut refinery in

Egypt. The new delayed coking unit

will be part of the US$1.5 billion

refinery modernisation programme,

using Bechtel's proprietary

ThruPlus® coking technology to

upgrade heavy oil into high value,

light hydrocarbon liquids.

Investment in the Assiut refinery

will increase production of

petroleum products to meet

Upper Egypt's growing demands,

while maintaining important

environmental standards. The

addition of a modern delayed

coking unit was determined to be

the most economical option to

allow the refinery to increase

complexity and eliminate heavy fuel

oil product.