HYDROCARBON

ENGINEERING

46

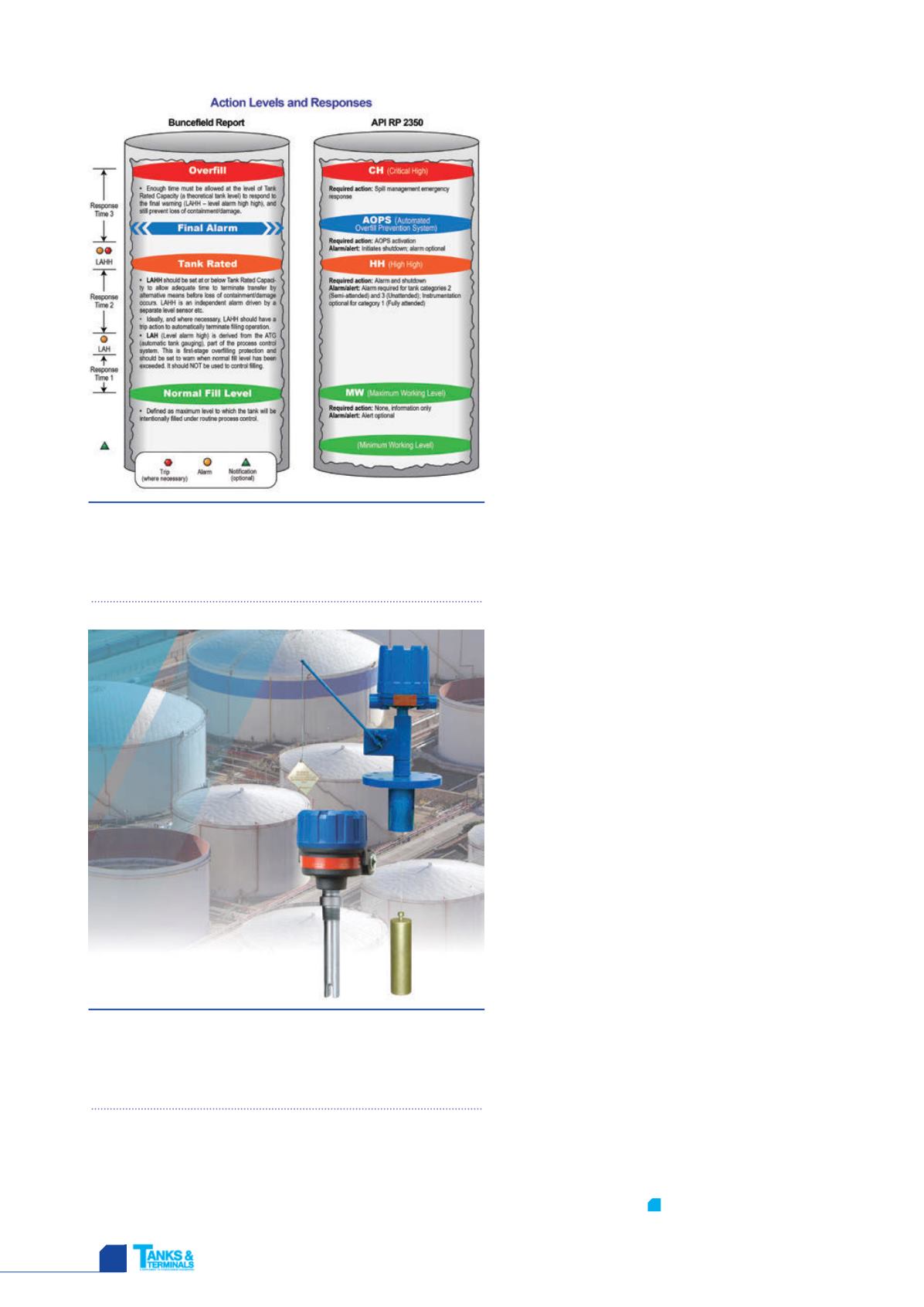

Based on customer approval of Letico’s reporting, the systems

integrators began the implementation phase by standardising on

equipment. Magnetrol was able to demonstrate a powerful

automated tank gauging system solution using the A15 single-point

top mount buoyancy displacer switch and single-point Echotel®

Figure 1.

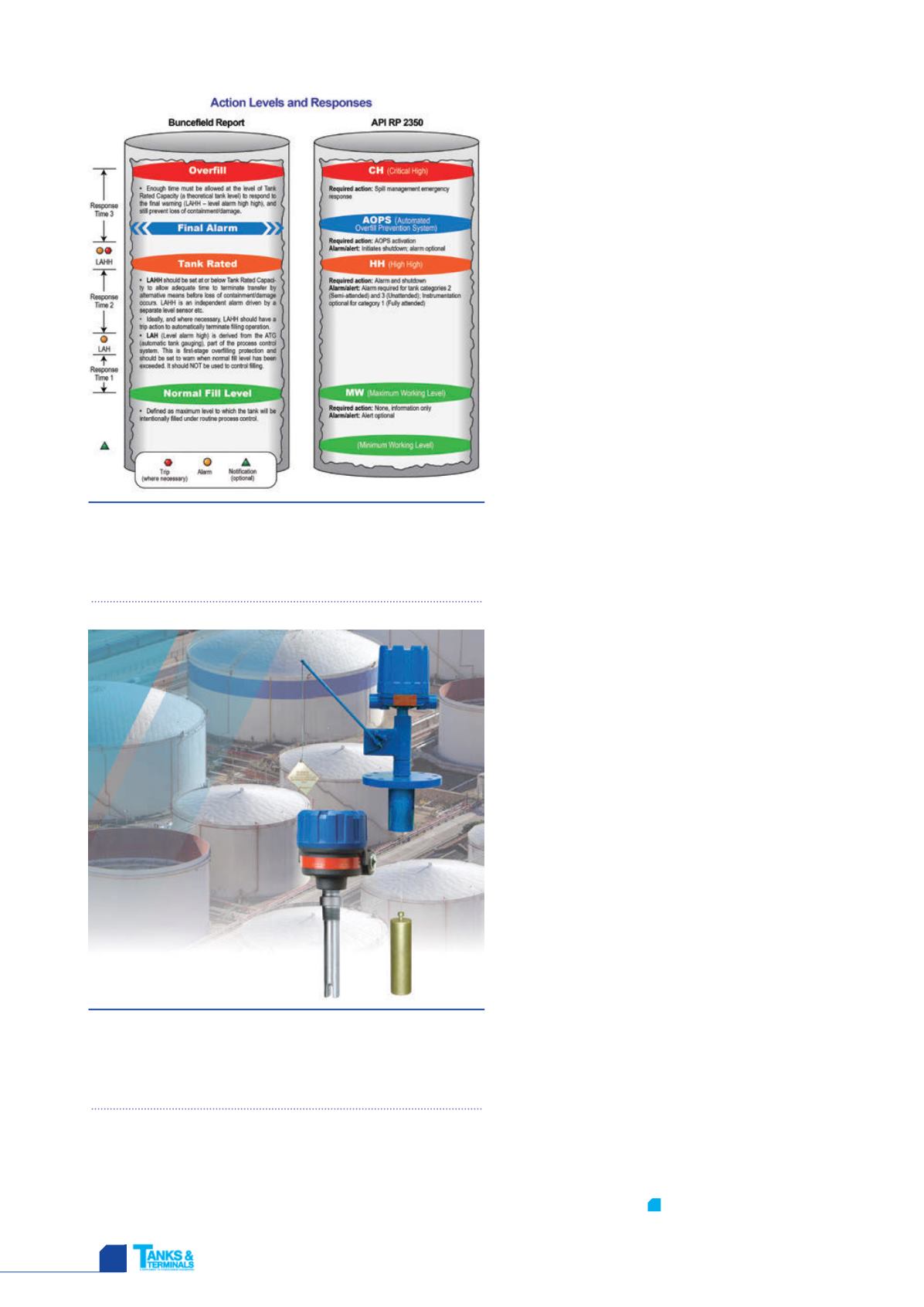

Since their publication, the MIIB Buncefield Report

and the API RP 2350 have been major drivers of process

improvement surrounding tank overfill prevention and share

similar overfill prevention system (OPS) recommendations.

Source: Magnetrol International.

Figure 2.

Letico standardised on the Magnetrol

®

A15

displacer switch and Echotel

®

961 ultrasonic switch across the

tank inventory for detection of tank floating roofs and direct

product detection in free space and stilling wells, respectively.

Source: Magnetrol International.

model 961 contact ultrasonic switch, with the A15 used to

detect tank floating roofs and the 961 used for direct

product detection in stilling wells, as well as free tank

space. The units were utilised as an independent high-high

alarm sensor.

The tank configuration was a critical consideration

when selecting technologies. The company had to specify

units for storage tanks with floating roofs and fixed

roofs – ease of installation and testing capability were of

paramount concern.

The SIL 2 suitable Magnetrol model A15 point level

sensor actuates at a discrete level and can detect the roof,

as well as the liquid level, should the floating roof become

submerged – a new requirement of the API RP 2350

4

th

Edition. The non-sparking, hollow-shell brass displacer

provides dual detection of both floating roof and liquid

levels. The units are equipped with a proofer manual

checker to enable proof testing.

The Echotel model 961 contact ultrasonic level switch

serves as a point level sensor that triggers the high-high

alarms and is suitable for SIL 2 applications. The unit has

both automatic and push-button, self-test ability to

enable proof testing. The diagnostics monitor the

electronics, transducer and piezoelectric crystal.

At this point of the project, Letico documented

comprehensive tank operational data, confirming accurate

dimensions, flow rates, response times and other metrics

for level calculations.

Using its extensive knowledge of the AP RP 2350

4

th

Edition, Magnetrol had created useful tools to allow its

customers to easily review the 4

th

Edition and take steps

to implement the new tank overfill prevention standards.

This ‘tool kit’ became instrumental to the Letico team’s

efforts, because it helped the company focus on what it

needed to do to deliver a successful installation to the

customer. It had to adopt a way of standardising on

nomenclature because each company uses different

terminology in its internal engineering practices. The

API 2350 4

th

Edition classified tanks, levels, alarms,

technologies and procedural systems, which gave Letico a

yardstick to use for its level calculation and

documentation. The worksheet and other materials in the

‘tool kit’ helped provide guidance for terminology

standardisation and overall overfill prevention process

(OPP) methodologies.

Conclusion

One of the most valuable impacts the 4

th

Edition has

made is the emphasis it places on safety instrumented

systems (SIS) and safety integrity level (SIL)

certified/suitable equipment.

The project’s results were instrumental in embedding

standardisation and documentation into a robust

operating process system and a culture of safety. Across

the organisation, workers are now thinking the same way

and looking at things the same way. Actions are

standardised, response times are measured, and

calculations are uniform. When there is a change in the

data, it is documented and specific modifications are

implemented as a result.

T&T