HYDROCARBON

ENGINEERING

54

n

Quality information relating to the fluid is always available

(density and viscosity), which means transparency on the

product and direct standard volume values are available

when required.

n

No upstream and downstream lengths are required,

resulting in a small metering skid footprint.

The newest generation of Endress+Hauser Promass coriolis

mass meters also offer a number of other advantages for

custody transfer systems, such as:

n

Best in class accuracy and high performance.

n

The capability to adapt to different fluid types and

conditions without effect on accuracy, meaning that there

is no need for specific onsite calibration to adapt to the

application.

n

Compact instruments that are easier and cheaper to install.

n

High levels of diagnostics, resulting in preventive

maintenance to avoid unexpected shutdowns.

Figure 5.

Case study 1: ship loading metering system

completed with portable master meter.

Figure 6.

Case study 2: standardised truck loading

metering systems.

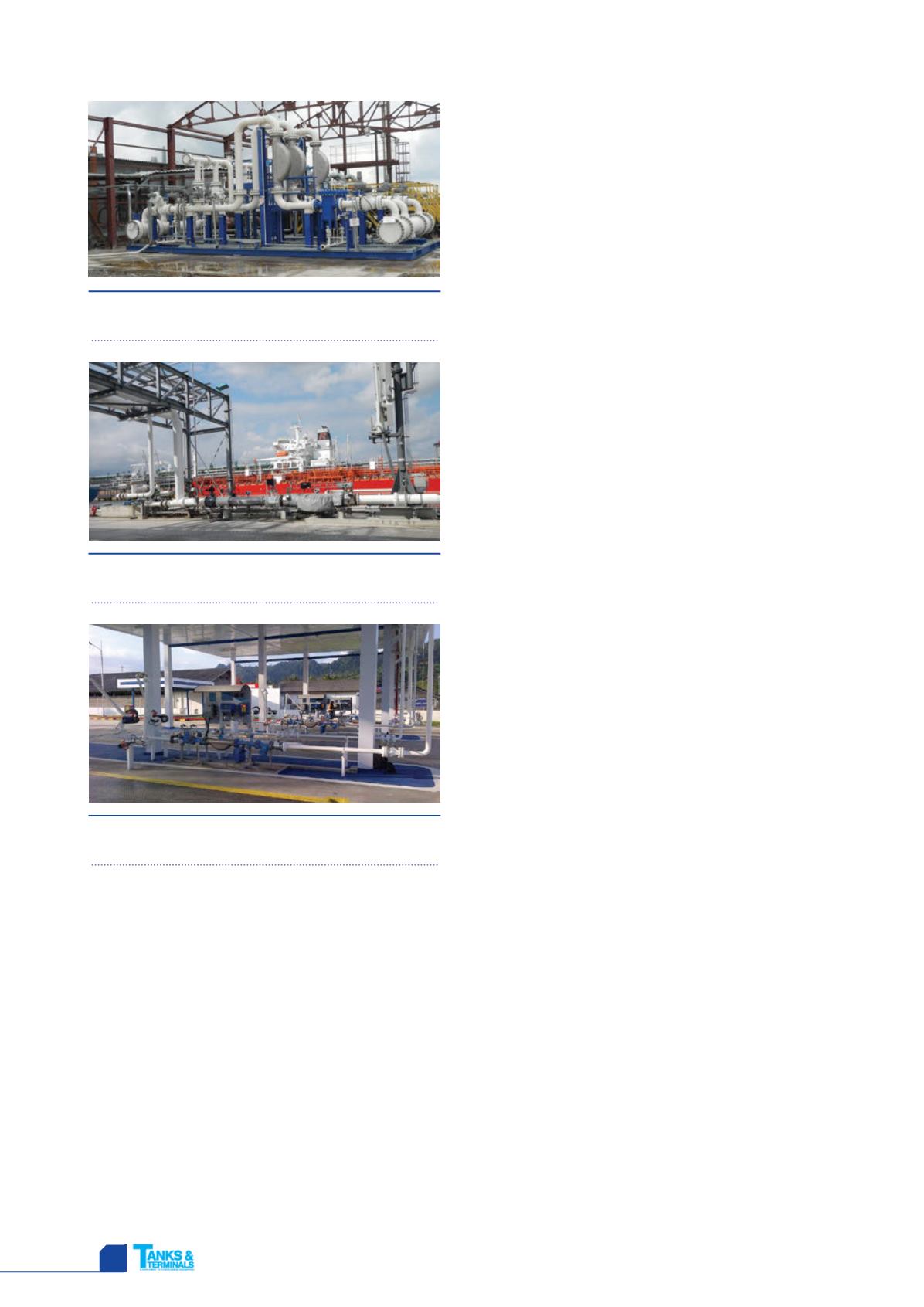

Figure 4.

Example of a built customised pipeline

custody transfer metering system.

n

The first four tube, 12 in. coriolis meter available on the market

(availability up to 4100 tph).

n

Designed to be completely independent of environmental

vibrations, resulting in easier installation without the need for

specific supports.

The company’s custody transfer metering system offering

includes both standard and fully customised solutions covering all

possible loading and unloading, blending and proving applications.

Standardised loading metering solutions

The company’s range of ‘plug and play’ modular units start from

basic ‘fit for purpose’ systems and grow into more complex

preconfigured architectures, depending upon the specific project

needs. All are designed to meet OIML-R117 and MI-005 standards,

as well as the API MPMS custody transfer requirements for truck

and railcar loading and unloading. These include LMS080 truck

loading, LMS100 railcar loading, LMS150 railcar loading,

OMS080 truck unloading, OMS100 railcar unloading, LPG080

LPG truck loading and vapour recovery, and modular blending lines.

A set of pre-selectable options are also available, for example: air

eliminators, grounding units, ID card readers and overfill

preventions, for ‘mix and match’ configuration and easy integration

into terminal automation systems.

Alongside the LMS range, customised turnkey systems can be

provided, from FEED engineering up to construction,

commissioning and after sales services, including LACT units,

pipeline metering (Figure 4), jetties systems for ship loading and

offloading, and blending and metering.

Case studies

Ship loading

A private terminal operator, which stocks diesel and heavy oil and

distributes it through ships, focused all its business on the reliability,

transparency, accuracy and operation time of these transactions.

The operator faced the challenge of loading different products

(heavy fuel oil and marine diesel oil) that were handled using the

same pipelines and jetties.

Due to fluid dynamic differences between diesel and heavy

fuel oil, the operator faced problems with achieving the same

performance from the installed mechanical meters and, in addition,

there was little transparency in the quality of the products (no

density information available). The operator found it necessary to

recalibrate the meters frequently, disassembling them from the

jetties and constantly extracting samples to understand which fluid

was being loaded. This resulted in lost time and decreased terminal

performance and quality, which is based substantially on the

number of ships that can be successfully loaded in a day.

Endress+Hauser proposed to replace the nine existing metering

systems, equipped with positive displacement meters, with new

MI-005 (MI-005 part of MIDMeasurment Instruments Directive)

approved metering systems, equipped with Promass X, the largest

coriolis meter available on the market today, which only has four

internal tubes.

As a result of the Promass X’s increased capacity, 100% of the

flow could be handled with only one stream. Furthermore, the

meters provided accurate and direct information related to the

density of the fluid metered, which allowed the operator to obtain

reliable fluid quality information without manual sample extraction

and analysis. The custody standard master meter was mounted on a