A fundamental tenet of an audit is that it should

be structured and methodical. Thorough preparation

is therefore key to achieving a successful audit. The

other advantage of preparation in advance of the

audit is that it allows the auditor to formulate ‘audit

criteria’.

Audit criteria can be thought of as a checklist, or

audit roadmap, which will help guide the assessor

during the audit. This can be a particularly useful aid

for less experienced assessors and help ensure that

the fundamental areas have been covered. The

weakness with this approach, however, is that it can

provide a rigid framework within which the audit

should take place and does not cater for situations

that the audit team did not foresee, and at worst

can blinker the assessor to issues identified within

the audit criteria, leading them to miss potential

issues that have not been predicted in advance.

Audit criteria should therefore be thought of as an

‘aide-memoire’ rather than a definitive list to follow,

and the audit should be ready to deviate or include

additional issues should they arise.

Traceability

One of the key requirements for any measurement

system is traceability to relevant standards, and

calibration traceability showing a complete chain of

calibrations from the device in question back to a

national standard reference device. This is no different

for assessors, which establish audit criteria and audit

questions. For instance, an assessor may wish to

investigate the installation of a flow meter and,

therefore, should be able to cross check the physical

installation with the relevant standard. Whilst this

should not prohibit an assessor from using their own

experience and intuition to investigate and report

potential issues, specific questions should be able to

refer back to a specific standard that governs practice

in that area.

Following the audit

In the wake of an audit, the assessor will compile a

report highlighting any problems or non-conformances

found. Audit reports can vary greatly in detail, from a

short list of issues found, through to a detailed report

outlining the audit criteria, detailing traceability and

presenting evidence to support each issue.

Although audits can be time consuming, resource

intensive and sometimes even stressful for those

involved, they are a vital aspect in the maintenance of

an effective measurement system. Furthermore, the

cost of neglecting to conduct them can be high. As

previously discussed, the financial exposure globally

on fiscal measurements alone could be in excess of

more than US$9 million/d for a metering uncertainty

of

±

0.25%.

While this level of uncertainty would be

acceptable in most cases, in situations where there

was a specific problem with some aspect of a

measurement system, the cost could be much higher.

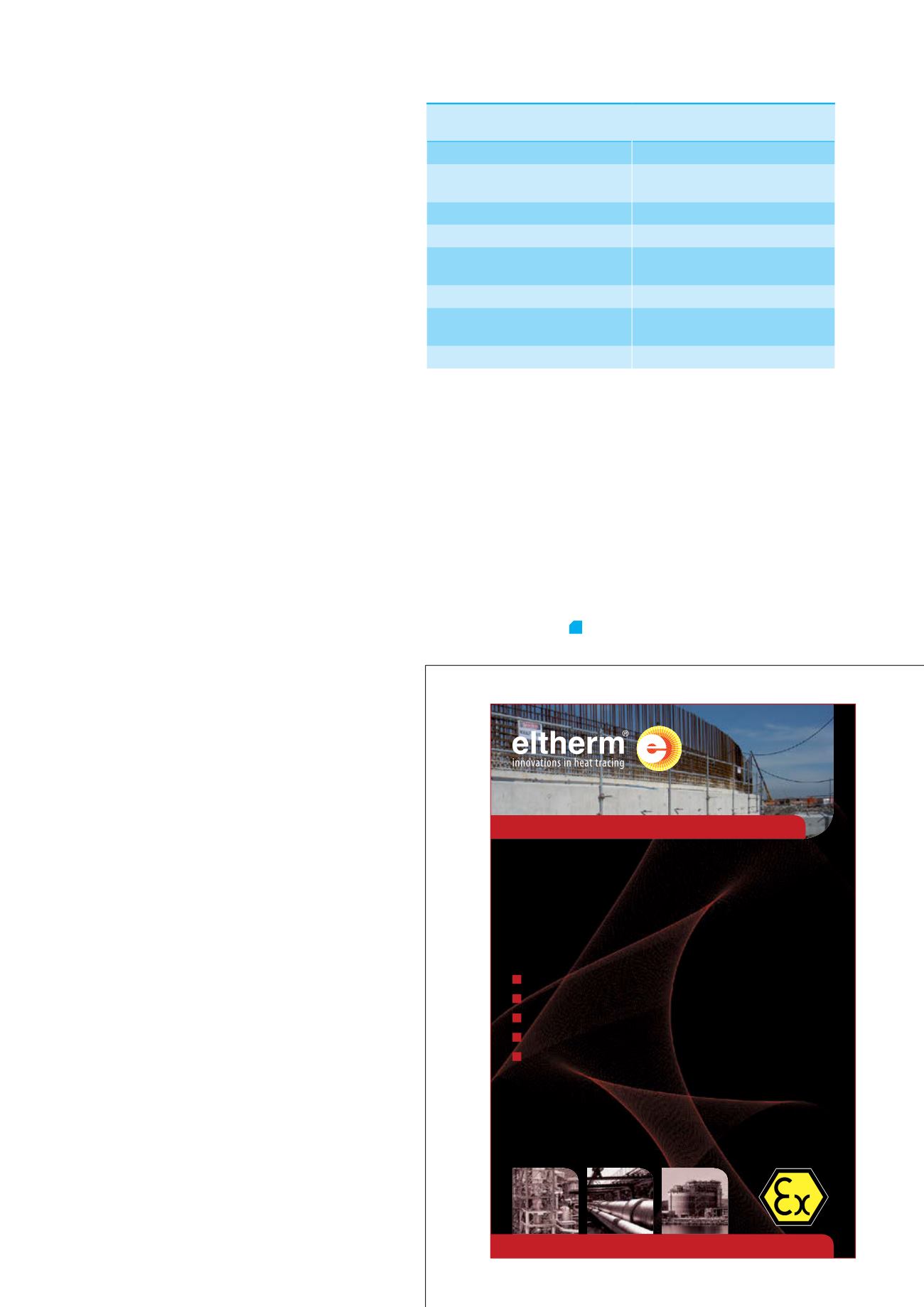

Table 1.

Measurement system problem and associated

cost

Description

Cost of error

Orifice plate not seated properly at

the bottom of the fitting

US$35 million under measurement

Failure to inspect orifice plate

US$6 million/y under measurement

Gas cooling prior to densitometer

US1 million/y over measurement

Liquid densitometer not calibrated Tens of millions of barrels under

measurement

User entered wrong prover volume US$25 million under measurement

Liquid entrained within gas in USM

installation

US$5 million

Non-representative sample taken US$10 million/y

Table 1 gives some examples of this from field experience, and gives a

flavour of the implications of specific problems in a flow measurement

installation.

Conclusion

It is clear from the examples given in Table 1 that even seemingly small

issues in a measurement system can have a large financial cost. This is

particularly true when applied to custody transfer applications

between hydrocarbon transfer and storage facilities, where

measurement accuracy is at a premium. The effort and relatively small

cost required to perform an audit, therefore, has the potential to avoid

a potentially large amount of expenditure if such faults can be

detected and corrected.

T&T

eltherm - LNG Tank Bottom Heating System

eltherm is a leading manufacturer and global supplier of elec-

trical heat tracing systems. With over 40 years of experience,

our team of specialists have been providing the industry with

heat tracing solutions to meet the most demanding require-

ments. With a continuous drive to provide the highest quality

and most exible and e cient design, we are your competent

partner for LNG tank bottom heating systems.

Turnkey-Solution from engineering to commissioning

2D and 3D Thermal Analysis

E cient and reliable control and monitoring systems

Safe and durable systems

High-quality heating cables, components and

accessories from own manufacturing site

The eltherm engineers would like to face your challenge also.

eltherm GmbH

Ernst-Heinkel-Str. 6-10, 57299 Burbach, Germany

Phone +49 (0) 27 36/44 13-0, E-Mail