HYDROCARBON

ENGINEERING

62

combustible vapour and ground could occur, as illustrated in

Figure 6. A direct or nearby lightning strike will cause a rise of

ground potential, and of all grounded objects, by hundreds of

thousands of volts in a fewmilliseconds. If the potential

difference between a grounded object or surface is exposed to

the vapour and the vapour reaches the electrical breakdown

strength of the vapour space, an arc will form and ignition will

follow.

FRT recommended practices

Historically for FRTs, shunts were used to ‘bond’ the floating

roof to the shell of the tank. A shunt is a strip of string steel,

affixed to the floating roof and sliding against the inside tank

wall. Unfortunately, shunts do not provide a positive, low

impedance bond between the floating roof and tank shell for

several reasons, including:

n

Heavy crude oil components, such as wax and tar, can

accumulate on the inside of the tank wall, thus increasing

contact resistance.

n

Corrosion (rust) on the inside of the shell will increase the

resistance of the bond between the shell and shunts.

n

Many FRTs are painted on the inside, typically with an

epoxy-based paint. If the inside of the tank is painted, the

paint will insulate the shell from the shunts.

n

Large tanks are typically out-of-round by several inches. If a

tank is elongated for some reason, the shunts will be pulled

away from the shell in the long dimension of the tank.

Independent third party testing, performed in cooperation

with the API and the Energy Institute in the UK, has shown that

arcing will occur at the shunt-shell interface under all

conditions; it does not matter if the shunts are clean or dirty,

new or old, neglected or well maintained. It also does not

matter if the inner shell walls are clean, rusty, painted or coated;

arcing will occur in all situations. This testing programme has

been well documented in API 545-A.

API RP 545 is the ‘Recommended Practice for Lightning

Protection of Aboveground Storage Tanks for Flammable or

Combustible Liquids’. NFPA 780 is the ‘Standard for the

Installation of Lightning Protection Systems’. Both standards

recommend installing multiple roof-to-shell bypass conductors

on floating roof storage tanks. During a lightning event,

Component C of the strike will be conducted by the bypass

conductors, thus preventing sustained arcing at the seal

interface (it is Component C that causes ignition). The bypass

conductors will ensure that the roof and shell stay at the same

potential during thunderstorms, thus mitigating the risk of

ignition of flammable vapours that may be present. There are

thousands of floating roof storage tanks currently in operation,

with the majority of them lacking sufficient bypass conductors,

thus increasing their risk of lightning-related fires.

Non-metal production tank

recommended practices

NFPA 77 is the ‘Recommended Practice on Static Electricity’.

API RP 2003 is the ‘Recommended Practice for Protection

Against Ignitions Arising Out of Static, Lightning, and Stray

Currents’. Both NFPA 77 and API 2003 recommend an internal

grounding conductor inside all non-conductive and lined tanks

being used to store a potentially combustible fluid. This internal

grounding conductor must be grounded to earth to effectively

Figure 1.

Lightning-related tank fire on internal

FRT – Caribbean Petroleum, Puerto Rico, 2009.

Figure 2.

Lightning-related fire at injection well

facility, Deanville, Texas, 2015.

Figure 3.

Illustration of current flows resulting from

lightning strike to tank shell (note that current flows

across the roof-shell interface in numerous locations).

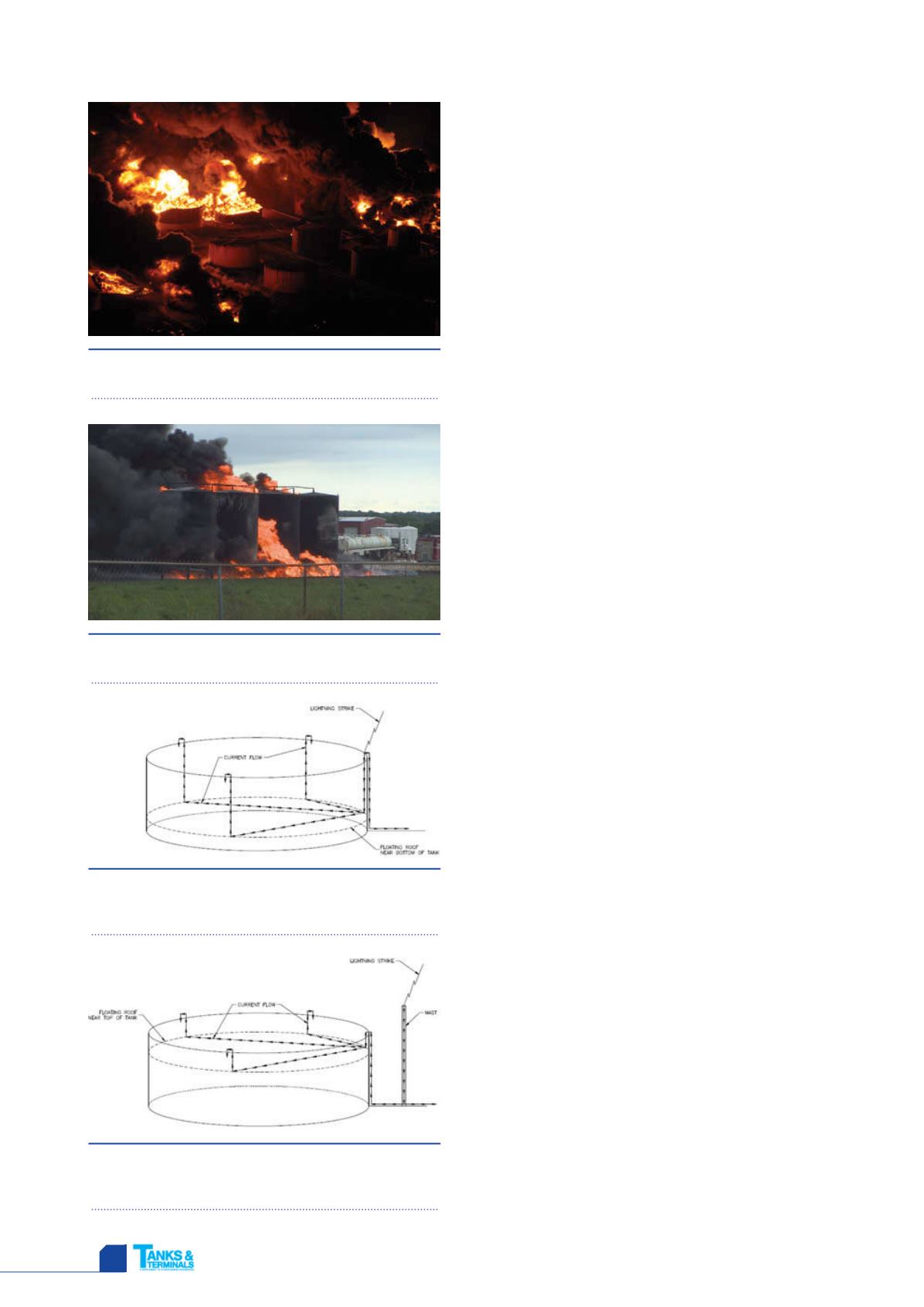

Figure 4.

Illustration of current flows resulting from

nearby lightning strike (note that current flows across

the roof-shell interface in multiple locations).