HYDROCARBON

ENGINEERING

66

onward sale through retail sites. Owing to the number of

companies involved in the distribution and marketing of

fuels, there is a need to ensure that a consistently high

level of competency is maintained. For this reason, the

industry has spearheaded the development of several

schemes to improve skills and safety:

n

A safe loading pass scheme (SLPS) for petrol tankers.

n

A petroleum driver passport (PDP) for petrol tanker

drivers.

n

A petrol retail safety passport for contractors

working at petrol stations.

n

A petrol retail operator training guidance for

personnel working at petrol stations.

The safe loading pass scheme

Demonstrating that risks are being managed in

accordance with CoMAH can be challenging when

equipment used in hazardous operations is not

permanently located or controlled by a site. This is the

case with petrol tankers entering and exiting a

petroleum terminal. For this reason, the SLPS has been

introduced in the UK.

The scheme is an industry created, owned and

managed code of practice and consists of an inspection

of road tankers’ parameters against agreed standards. It

can form part of a CoMAH demonstration to the UK

regulator, identifying how major accident hazards are

managed, and compliments existing vehicle inspection

law, as defined under ADR. It is recognised by members of

the UK Petroleum Industry Association (UKPIA) and the

Tank Storage Association (TSA), which together represent

the majority of petroleum terminals in the UK. These

participating sites enforce the scheme at the terminal’s

entry point through verification of the validity of the SLP.

The SLPS sets standards for a road tanker inspection

to provide additional assurance to a terminal operator

that the vehicle is safe to load fuel. These checks are

carried out every six months and include an inspection

of:

n

Electrical equipment and electrical continuity

(i.e lights, work lamps and aftermarket equipment).

n

General equipment (i.e tyres and fire extinguishers).

n

Tank and tank top (i.e general condition, foot-valves,

drainage, manhole covers and pipework).

n

Tank internal (i.e overfill protection sensors and

breather valves).

n

Control system (i.e control cabinets, anti-drive away

function, guard bars and foot valve operation).

n

Labels and hazard panels.

n

Loading connections (i.e loading adapters and

overfill protection system sockets).

To maintain a high level of consistency and quality,

only those workshops that meet the scheme’s standards,

and technicians who have passed the scheme’s training

course, are permitted to carry out a road tanker

inspection and issue a SLP.

Since the scheme’s launch in 2015, 62 workshops

have been successfully assessed, more than 200

technicians have been trained and over 5500 passes

have been issued.

Petroleum driver passport

The PDP is a UK wide scheme that ensures that all

petroleum tanker drivers are trained and assessed to a

consistent industry standard. It is a voluntary scheme,

backed by the UK Government, which has been designed

and implemented by industry. The PDP is a driver card,

which all petroleum tanker drivers should have

regardless of their employer, type of vehicles, grade(s)

of petroleum product, or loading point.

The scheme has been developed to provide the

knowledge and skills required by a petroleum tanker

driver that are not covered by ADR. Therefore, it has

been designed to sit alongside existing tanker driver

regulation and has a five year renewal cycle, in line with

an ADR licence.

At the heart of the PDP is a standard, which specifies

all of the required knowledge and practical skills for a

petroleum tanker driver. To gain their passport, drivers

must attend classroom training and pass both a written

assessment and a practical on the road assessment.

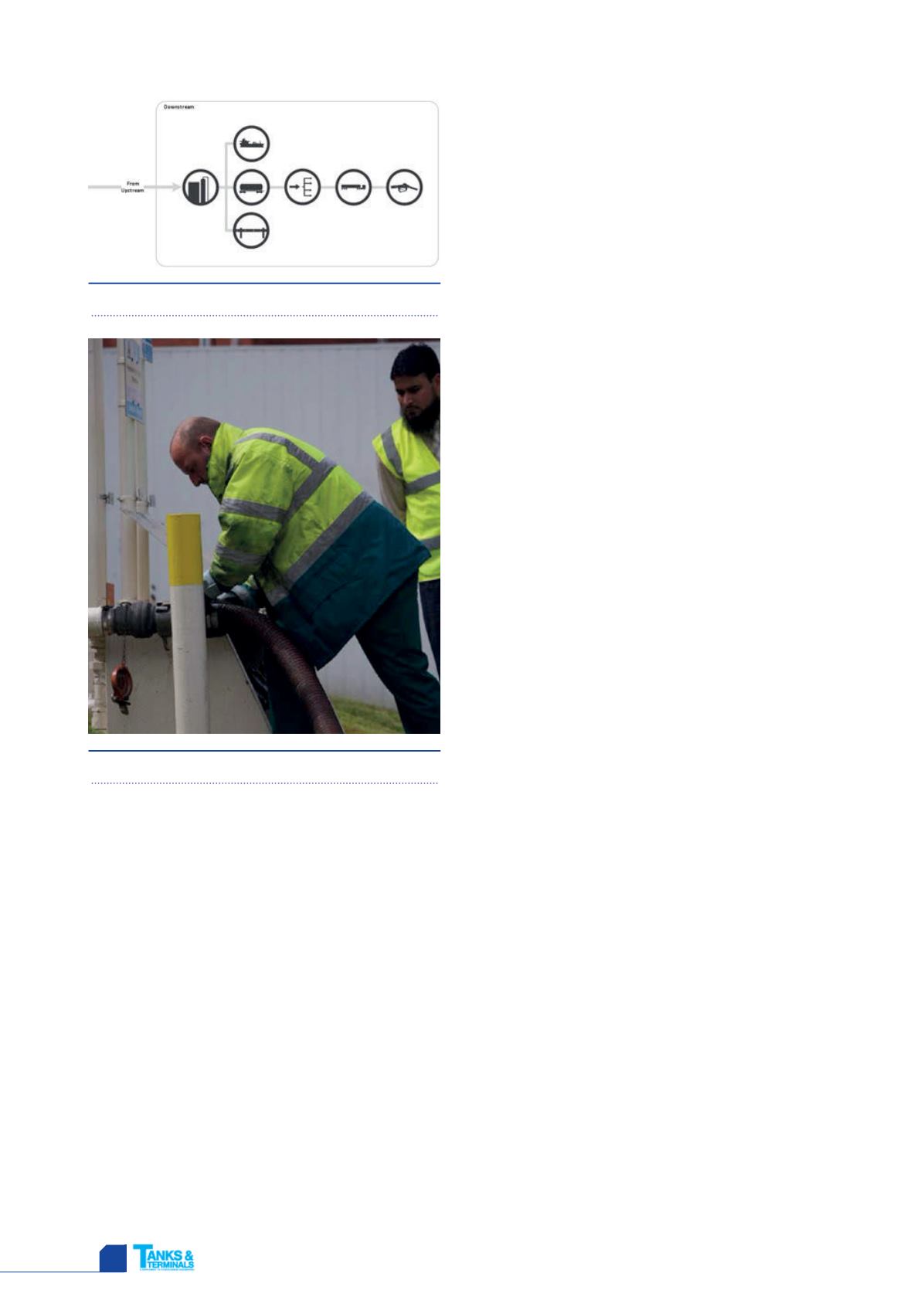

Figure 1.

The fuels supply chain.

Figure 2.

Tanker delivery.