HYDROCARBON

ENGINEERING

76

also brings into play the fact that the coating may need to be

compatible with cathodic protection, a feature that is not

necessarily a given for coating performance.

It is interesting to note that in the latest revision of

NORSOK (Rev 6), the subsea system 7 has now been

altered to incorporate different scenarios, one of which is

a higher temperature system for immersion. System 7C

has now been created to cover the immersion of carbon

steel at >50˚C, which highlights the need for these types

of paint specification in the industry.

These changes mean the role that protective coatings

play is under more scrutiny as they are forced to deal with the

higher temperatures and pressures. High temperatures and/or

high pressures exert a huge stress on linings and coatings,

which then forces the paint manufacturers to develop newer

technologies that can cope with these onerous conditions.

Epoxy-based coatings are tried, tested and well

understood within the coatings industry. Typically, most

‘standard’ epoxies would not withstand immersion at

temperatures greater than 60 - 80˚C, so when dealing with

the higher temperatures, alternative technologies need to be

considered. Phenolic/novolac epoxies have been used

historically for these types of situations, although the top end

immersion performance of some of these can be limited to

around 99˚C. This is also the same when considering high

pressure systems. All coatings have some degree of porosity,

so higher pressure has a tendency to force more air particles

or fluids into the paint film, potentially causing premature

breakdown. Creating a more highly cross-linked film,

combined with the correct pigmentation, can help produce a

much more impermeable coating, which is less susceptible to

damage from high pressures.

Downstream: the need for flexibility

Downstream asset owners' requirements, including storage

terminals, have also expressed the need to have a degree of

flexibility over their tanks, and the ability to swap and

change cargoes from tank to tank is being seen as a more

attractive proposition, effectively ‘future-proofing’ the tanks’

internal lining system. By investing in a lining with resistance

to all potential commodities and temperatures, storage

terminal owners gain the ability to adapt to their client’s

needs and enable them to react at short notice to store

cargoes without the need to re-line the tanks.

Storage flexibility ultimately means being able to cope

with some of the more aggressive cargoes that may be

stored so a robust coatings manufacturer needs to be

selected in conjunction with the owners requirements. The

other advantage to this is to be able to provide a single

solution in order to keep things simple, which is another

message being signalled to the coating manufacturers.

Need for speed

The other aspect to consider is the lining of such tanks or

vessels onsite. Often, there is a need to get the tanks relined

as soon as possible to prevent costly downtime and reduce

the project duration to minimise costs. This is especially true

in refurbishment projects. Fast-curing coatings are becoming

much more popular as these can now enable tanks to be

returned back into service in 24 hours or less after application.

Inspections on the paint film cannot normally be carried out

until the film is sufficiently cured and hard enough to resist an

inspector walking on the film or carrying out standard

inspection tests. These may be as simple as dry film thickness

(DFT) readings or a potentially damaging adhesion or holiday

detection test.

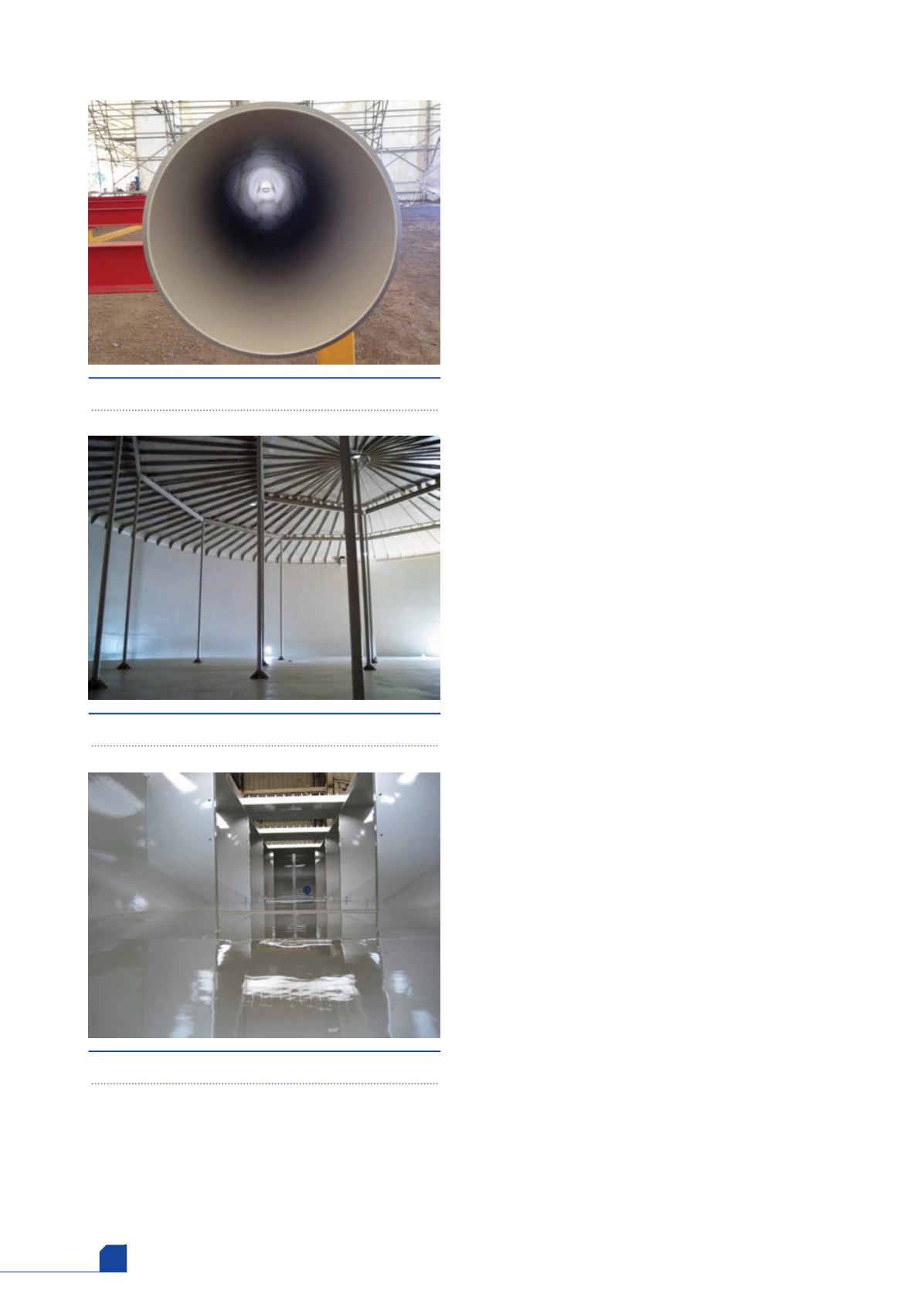

Figure 1.

Pipe lined with Nova plate.

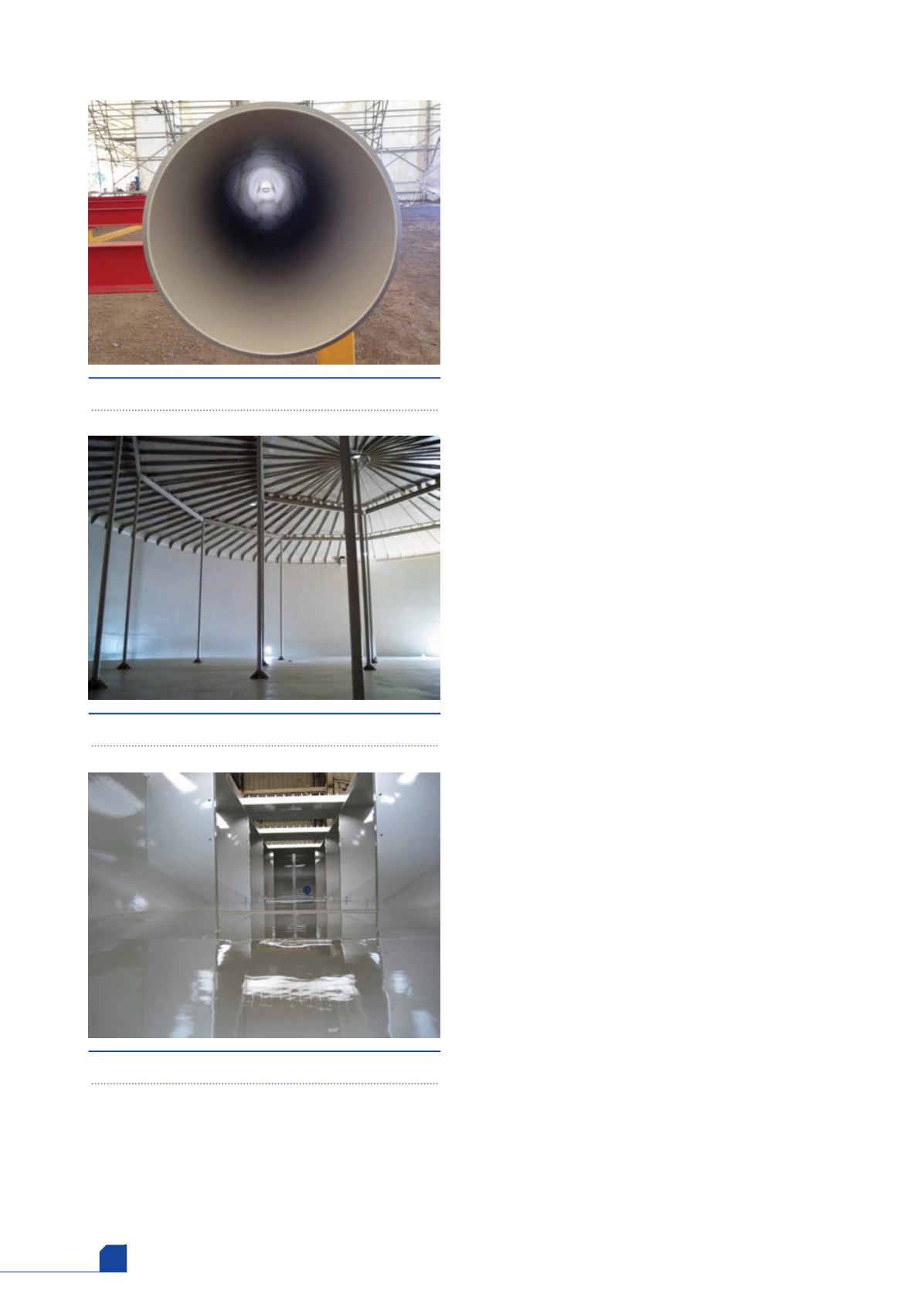

Figure 2.

Internal view of tank.

Figure 3.

Tank linings.