HYDROCARBON

ENGINEERING

78

Apart from the curing speed itself, another feature that

can assist in enabling the fast return to service of a lining is

the ability for it to be applied in a single coat. Good painting

practice would suggest that the likelihood of having low

areas of DFT would be minimised by being applied in two

coats, the theory being that should a low area be applied

during the first coat, the second coat is likely to be able to

cover this and build up this area to an acceptable thickness.

With recent advancements in lining technology, good lining

systems with a flexible DFT range have been developed to

enable the system to be applied in one coat. This helps to save

application time and avoids overcoating issues such as

maintaining the cleanliness between the coats, and applying the

second coat too soon or at the other end of the spectrum, too

late. The use of linings, which have no added solvents in the

formulation, help as this reduces the chances of pinholes or

voids being formed, and also prevents the risk of solvent

entrapment. As always, a good inspection regime and attention

to quality should help ensure that a defect-free film is achieved.

Safe and sound

One of the key properties is to be able to apply the coating to

the specified thickness without the risk of any sags or runs

forming. This allows the applicator plenty of scope for

over-application without causing any defects caused by a high

film thickness. It would then go without saying that such a

coating must be able to be applied at high film thickness and

still be able to perform successfully in its given environment

and conditions. A higher film thickness does not necessarily

equate to better or longer performance, as some coatings

become more brittle at higher thickness with the potential to

crack, particularly under onerous conditions. A ‘flexible DFT’

single coat lining system has to tackle this challenge providing

adequate film flexibility and cohesiveness even at higher dry

film thicknesses.

Another issue to consider is of safety, particularly with

tanks or vessels, which would be classed as ‘confined spaces’

by health and safety legislation. The use of solvent-borne

coatings is becoming less desirable due to the extra

precautions and measures that must be put in place to deal

with this, and so the use of ‘solvent-less’ or ultra high solids

products is becoming the norm. A few of these ultra high

solids products have the added benefit of providing

inherently better edge coverage due to the naturally higher

viscosity than traditional solvent-borne products. The higher

the film thickness on the edges, the more durable the coating

would be expected to be in these areas and subsequently

better longevity of the coating should be seen.

Conclusion

In order to simultaneously respond to the changing needs

described above, owners and operators of storage tanks

and vessels are turning to coatings manufacturers.

The use of glass and ceramic particles in conjunction

with a novel phenolic novolac resin system has led to a

new formulation platform for coatings that is capable of

withstanding higher pressure, higher temperature, a

broader range of cargoes and enabling quick curing single

coat application for faster return to service.

As well as providing a better barrier (or a more

‘tortuous path’) for any moisture or chemical present in the

cargo to migrate through the film, the ceramic and glass

particles help to provide toughness and moderate the

mismatch in the coefficient of thermal expansion with

steel substrates. The novolac resin system is a key element

in providing the additional film cohesiveness and film

forming quality, with its fast curing, user friendly and

compatibility with a single coat application.

The coatings industry is working hand in hand with the

asset owners and applicators to ensure that these coatings are

able to satisfy the needs and requirements of all concerned.

This new technology platform is now being translated

in real products. The first of such next generation linings

have been well received by process vessel operators, and it

is thought the same platform could also be translated over

to the demanding subsea process arena.

Such linings give numerous benefits: flexibility of cargo,

speed of cure, which results in reduced downtime during

maintenance, good protection over an extended period of

time, and good application properties, which result in

excellent one coat systems. All of which mean storage tanks

and vessels will continue to be operated safely and

efficiently while meeting the challenges posed by the

modern oil and gas industry.

T&T

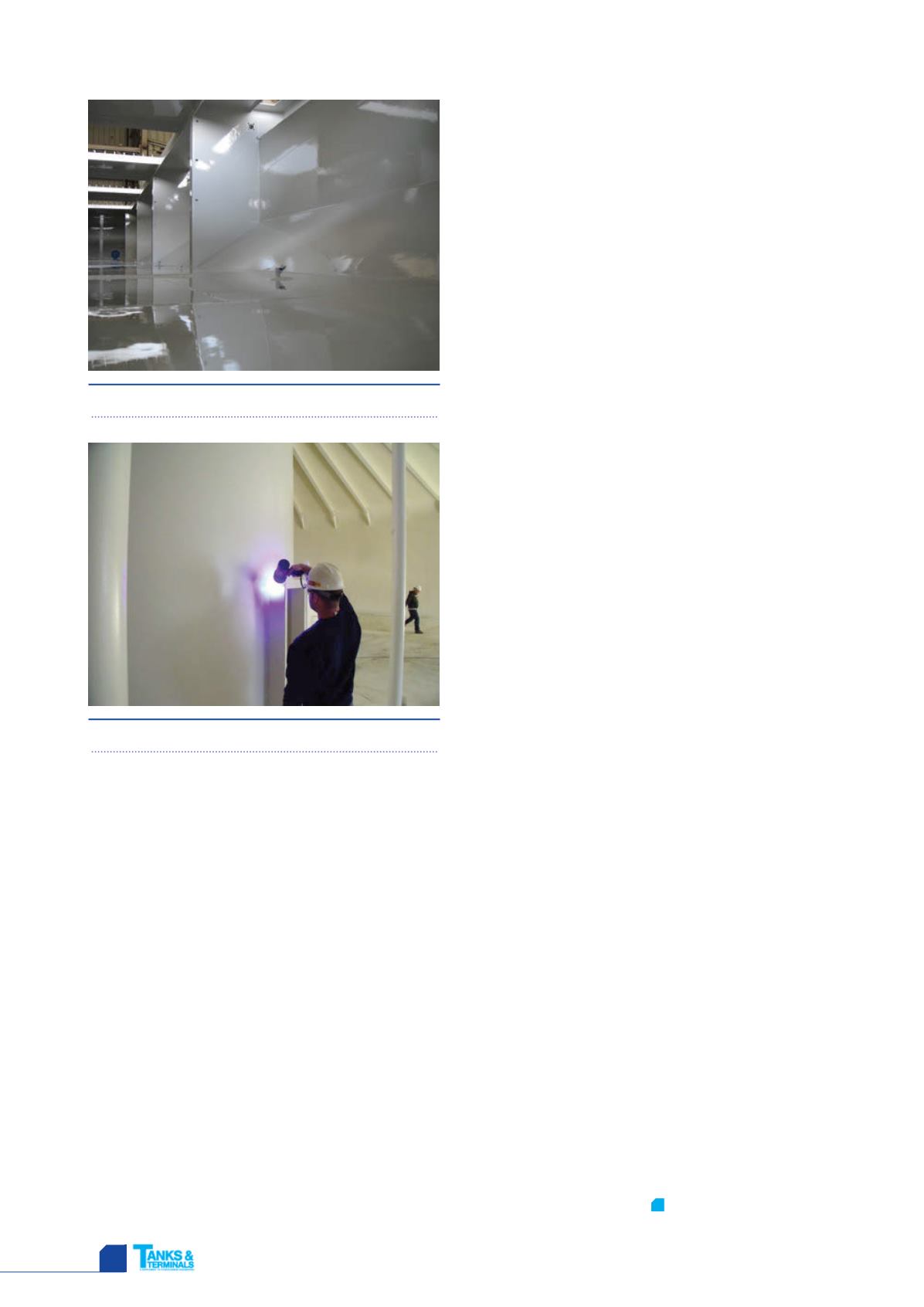

Figure 4.

Downtime of tanks is a major issue.

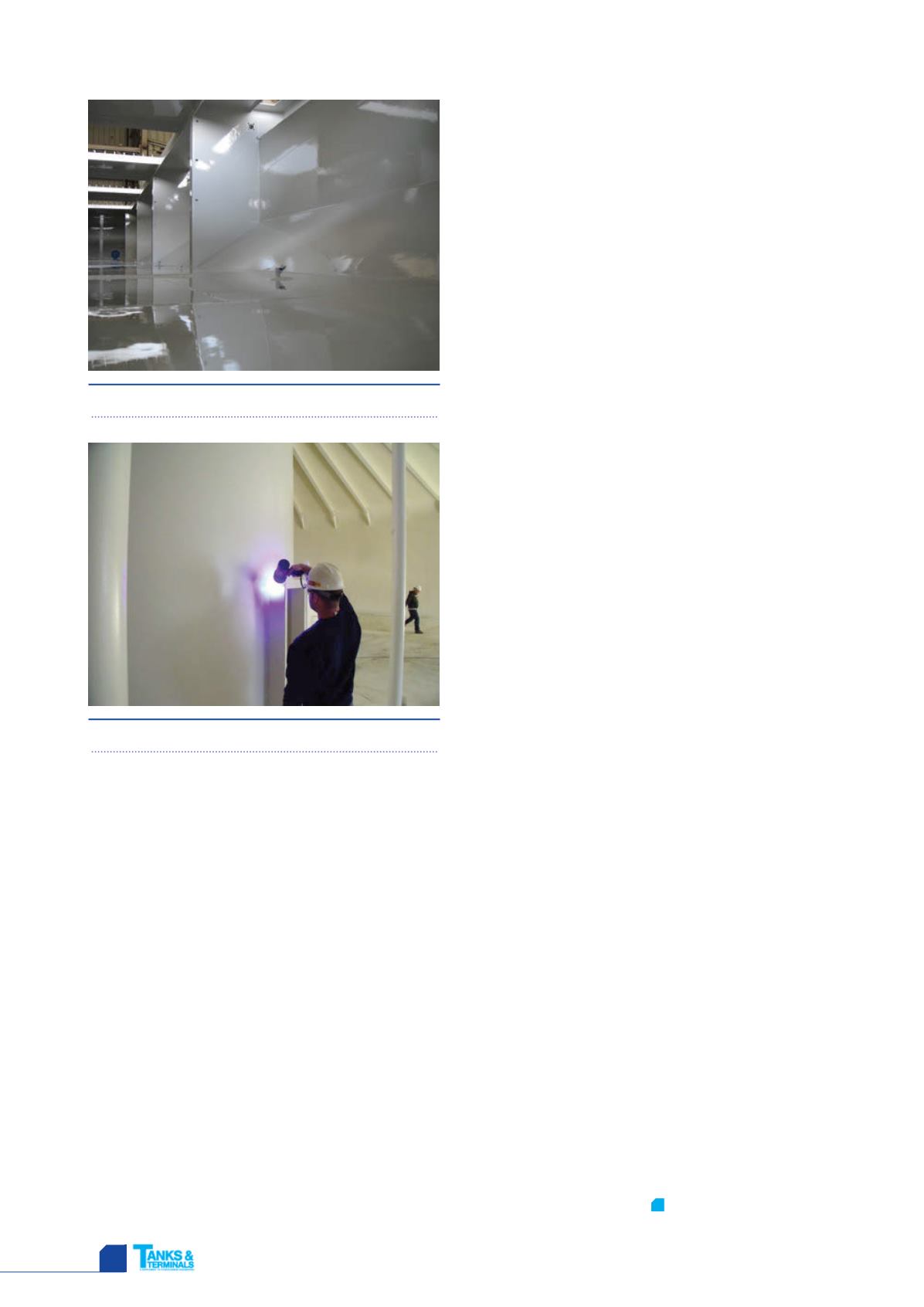

Figure 5.

Tank testing.