HYDROCARBON

ENGINEERING

74

n

Minimising cabling requirements.

n

Minimising operation shutdowns during implementation.

n

Design and implementation of SIL 2 certified safety

interlock loop of overfill protection system standards.

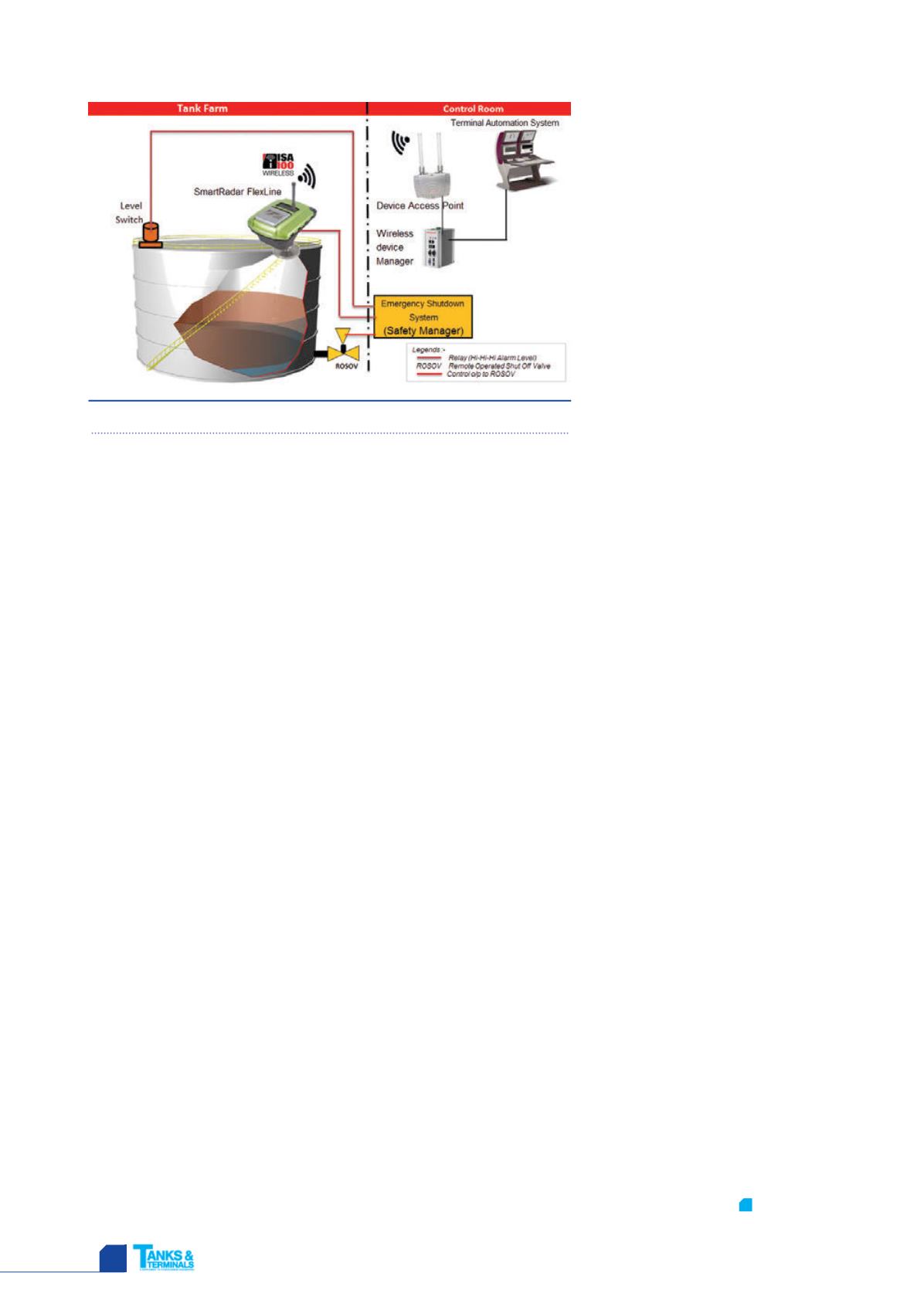

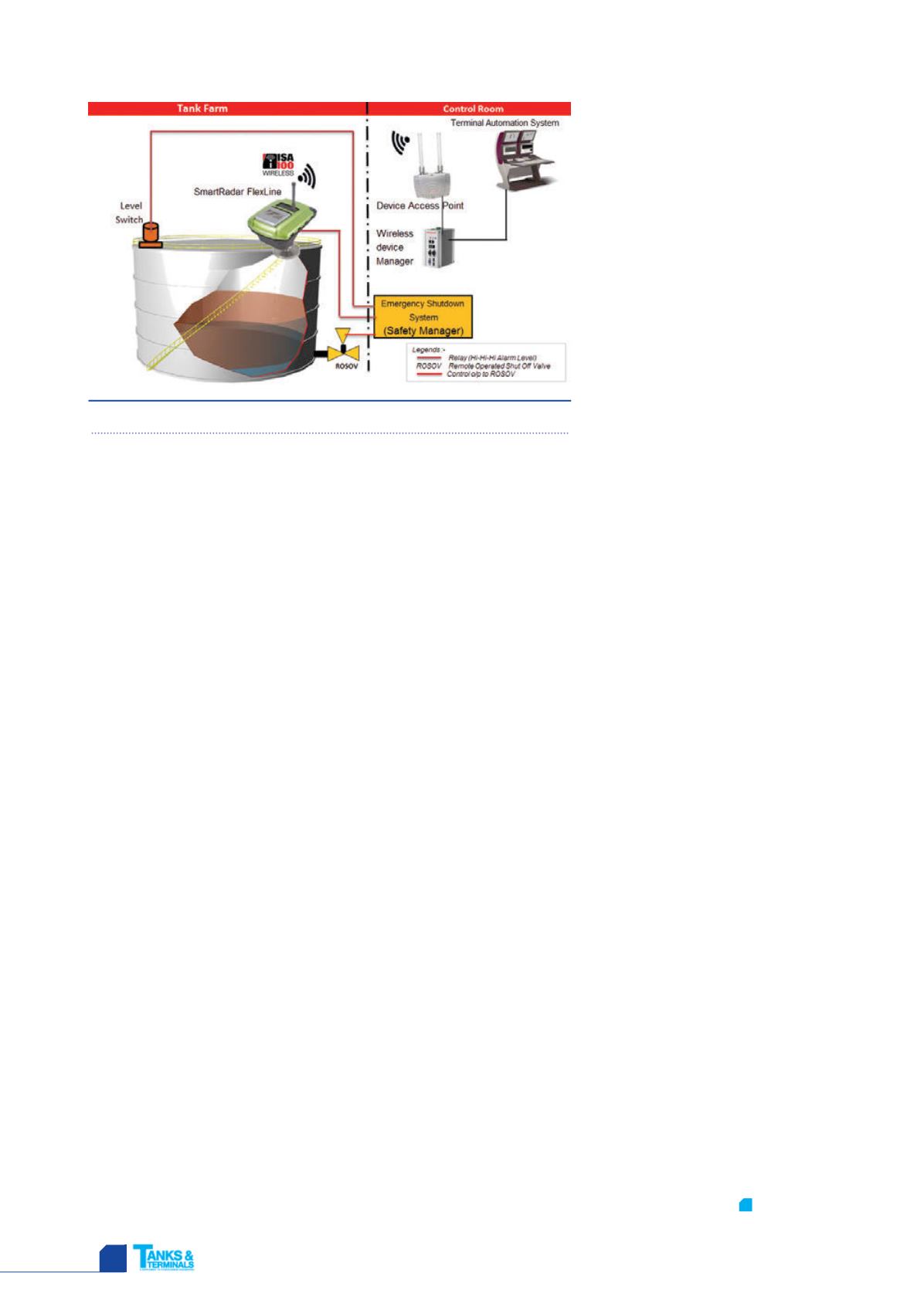

The loop design consisted of sensors (radar level gauge

and level switch), a logic solver (ESD) and the final control

element remote operated shut-off valves (ROSOVs). The

design of a SIL 2 rated loop required critical analysis of

sensor and logic solver safety-related data.

The SIL certified radar gauges are independent and

separate from the existing tank gauging system. Major design

considerations for selection of the radar gauges included:

n

SIL 2 (or better) certification of radar gauges and its

safety function, by an accredited third party safety

certification agency, as per the latest IEC 61508 safety

standard.

n

Capability of hard wiring of safety function (relay

output) to ESD system.

n

Transmission of level measurement data over wireless

protocol to minimise signal cabling, and availability of

the level data as additional inputs in terminal

automation system.

n

Performance of radar level gauges to provide an

accurate and precise level measurement and to perform

as overfill protection device through its safety function.

n

Proven performance record of radar level gauges in class

‘A’ and class ‘B’ products.

n

Assured performance of radar level gauges in existing or

new stilling wells in floating roof tanks and man holes

on top of cone roof tanks.

n

Design and deployment of low accuracy radar level

gauges for new fire water tanks, with wireless level data

transmission capability to the control room.

Solution

HPCL chose Honeywell’s SmartRadar FlexLine for

implementing the requirements of this critical project.

SmartRadar FlexLine combines new software algorithms

with Honeywell Enraf’s planar antennae technology to

provide precision levels demanded for custody transfer

accuracy.

Honeywell’s gauging solution features

a modular design and flexible architecture

that would allow the radar level gauge to

synchronise with multiple third party

applications and environments, and also

address the specific requirements of the

safety enhancement project. It offers high

flexibility that can be used for dedicated

tank applications such as independent

overfill protection, floating roof

monitoring, rim fire detection, roof

immersion compensation, etc. The

FlexLine wireless option reduces the cost

for wiring infrastructure and increases

flexibility, as various instruments can be

added to the network without adding

cables. The radar tank gauge is also

certified for use in custody transfer

applications.

The enhanced performance signal processing enables

the radar tank gauge to provide an accurate level reading,

even in difficult applications (close to the tank shell), and

prevents the need for a costly stilling well. The FlexLine

radar tank gauge can be used in overfill protection

applications, while additional diagnostics have been

added to detect hardware failures, and a 2004D voting

algorithm detects, reports and isolates failures on the

boards without interrupting the loading or unloading of a

tank.

HPCL’s chosen solution is SIL certified by TÜV. The

safety instrumented function design for overfill protection

included the following main criteria:

n

Loop average probability of failure on demand

(PFDavg): the PFD value contributes to achieving the

target loop PFD as defined in IEC 61511, bringing down

safety loop budgeting.

n

Architectural constraints: meeting the requirements of

minimum SIL 2 per IEC 61511.

n

Proof testing requirement of primary sensor (radar) and

loop (SIF): meet or exceed loop proof test requirement

of once in 10 years.

The overall design of the ESD system, considering other

safety loops within each location, was thoroughly and

carefully scrutinised by HPCL. The entire process resulted in

a sophisticated safety system with end to end

consideration of all safety features.

Close to 600 product storage tanks, distributed in

63 project locations, are covered in HPCL’s safety

implementation project. Honeywell’s SmartRadar FlexLine

is being delivered to all locations through HPCL’s

integrators, including 23 locations on a turnkey basis.

Conclusion

The enhanced safety project has enabled HPCL to reduce

financial and environmental risks. The safety certified gauge

enhances safety by actively guarding and alarming. HPCL

has increased terminal efficiency with their

implementation, assuring onsite accuracy, which helps

optimise available storage capacity and product movement

guidance, and improves resource planning.

T&T

Figure 3.

Design of overfill prevention safety rated loop.