The applications were easy to implement with the technical know how of its

in-house IT engineers. The company was ready for production immediately after just

two weeks of training.

Making the difference

Any oil and gas project scope of work (SOW) requires both knowledgeable staff and

the best software tools available to optimise efficiency in project execution. Having

the right software solution can make all the difference between success and failure.

In the case of the SOCAR AURORA Fujairah Terminal FZE project, MUC needed a

software solution that would satisfy its FEED requirements while allowing it to

expedite its workflow activity rapidly and cost effectively to meet the schedule of a

fast track project.

Efficient design

Intergraph’s CADWorx Plant Design Suite provided drawing and database

connectivity and 3D modelling utilities. The series of design tools includes intelligent

process and instrument diagrams, structural steel, an equipment modeller, an

auto-routing utility for rapid piping design and layout, design review for visualisation

and construction coordination, automatic isometric drawing production, plus

automated bills of material reports to support procurement needs.

The bi-directional links between CADWorx and analysis programs for pipes and

vessels enabled MUC designers and engineers to easily share information while

keeping the drawings, models and related information continuously synchronised as

changes were made throughout the project design workflow. Meanwhile, the fast

processing and highly refined user interface features in CADWorx empowered users

to work efficiently together, even on large models.

Project specifications

Key to the success of any project is the ability to manage project specifications. The

flexibility of the CADWorx Specification Editor enabled CAD managers to effectively

develop and manage projects piping specifications and satisfy a variety of project

requirements. Inevitably, project specifications may evolve and change over time

and/or from project to project. The ease by which CADWorx specifications can be

changed is remarkable. Similarly, these changes can then be easily updated and

shared with designers in real time. Exporting and importing piping specifications in

Microsoft Excel format completes the process and enables documentation of

project piping specifications.

Piping isometric and general arrangement drawings

Producing project deliverables is just as important as design. Quality piping isometric

drawing production is accomplished with Intergraph Isogen. Isogen not only

automates the generation of piping isometric drawings but also enables

pre-fabrication benefits with the confidence that piping spools will fit the first time

and minimise field fitment during construction.

Adding value to the CADWorx Plant Design Suite is OrthoGen, which automates

the production of general arrangement (GA) drawings. Like Isogen, OrthoGen can

reduce the time and cost of producing project deliverables, all of which pays big

dividends to the design firm, project execution, and, ultimately, the client.

Conclusion

No matter the price of oil, storage facilities will always be required to support the

global economy. MUC has benefitted from a variety of modern technology tools to

quickly and successfully complete the vital SOCAR AURORA Fujairah Terminal FZE

project.

T&T

References

1.

/.

2.

/.

3.

.

4.

.

5. 2005 Elsvier Ltd.

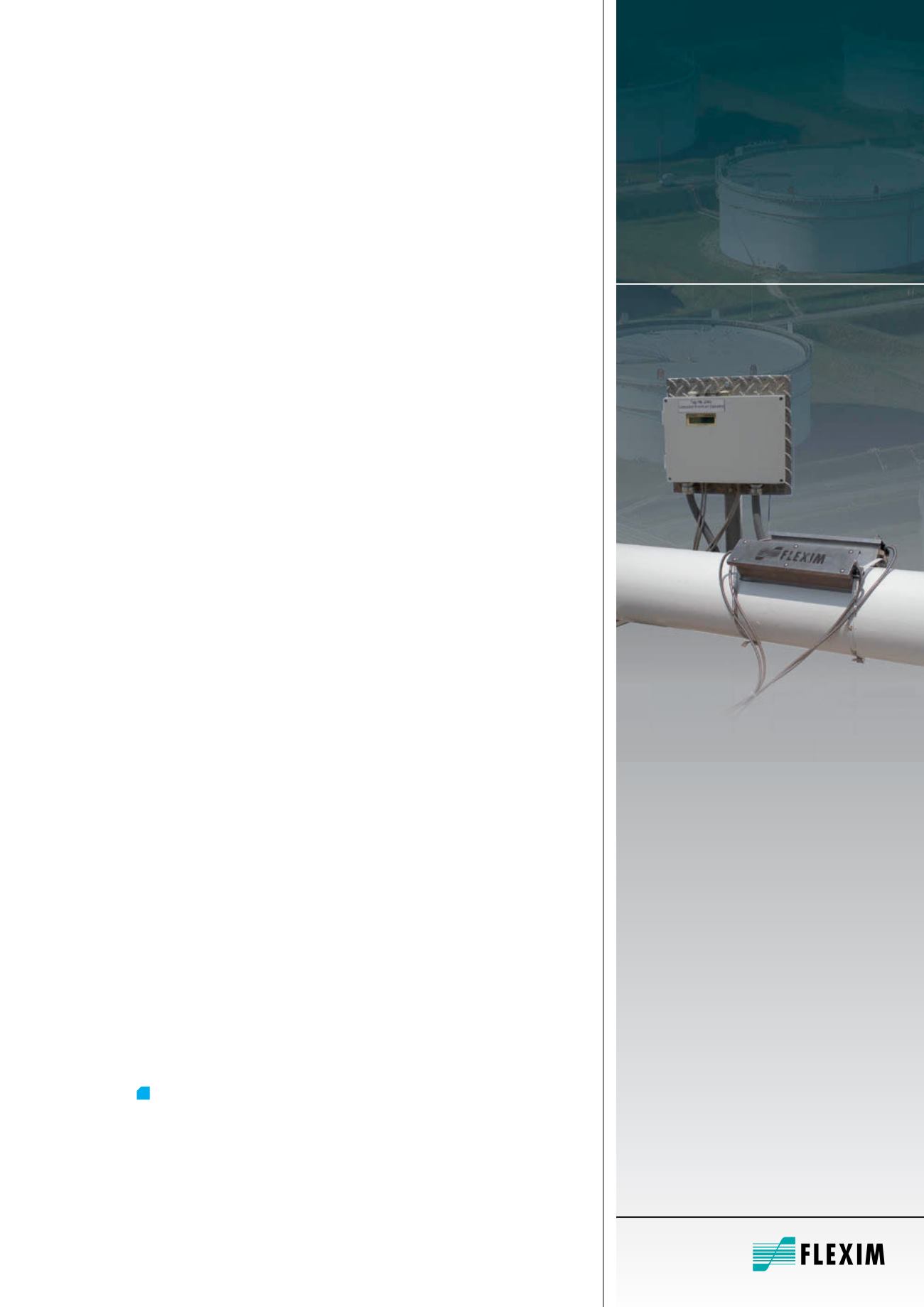

Looking for an

accurate mass

flow and media

detection of

hydrocarbon

products?

FLUXUS

®

HPI

FLEXIM’s flow measurement

solutions can be used in any

environment - applications in

hazardous areas and even in

flooded pits are not an issue.

The Fluxus HPI can be used for

continuous measurement of flow

as well as for media or interface

detection. Simply clamped onto

the pipe without the use of

gels, the highly rugged system

never loses signal giving you

accessibility at all times with zero

hazards.

The non-intrusive flow

meter for hydrocarbon

products handling:

Storage tank farms

(tank dewatering) & Barge

loading stations

Pipelines (bulk and product)

Hydrocarbon product

terminals