HYDROCARBON

ENGINEERING

36

down to proper compensation for changes in volume caused

by temperature variations.

n

DeltaV automated control driving valve actuators can create

lineups in an instant, eliminating the need for operators to

walk through and check potentially dozens of valves and

segments over thousands of metres.

n

Instrumentation can detect spills and determine where other

releases are happening in a facility. Spilled product wastes

money in addition to creating HSSE issues.

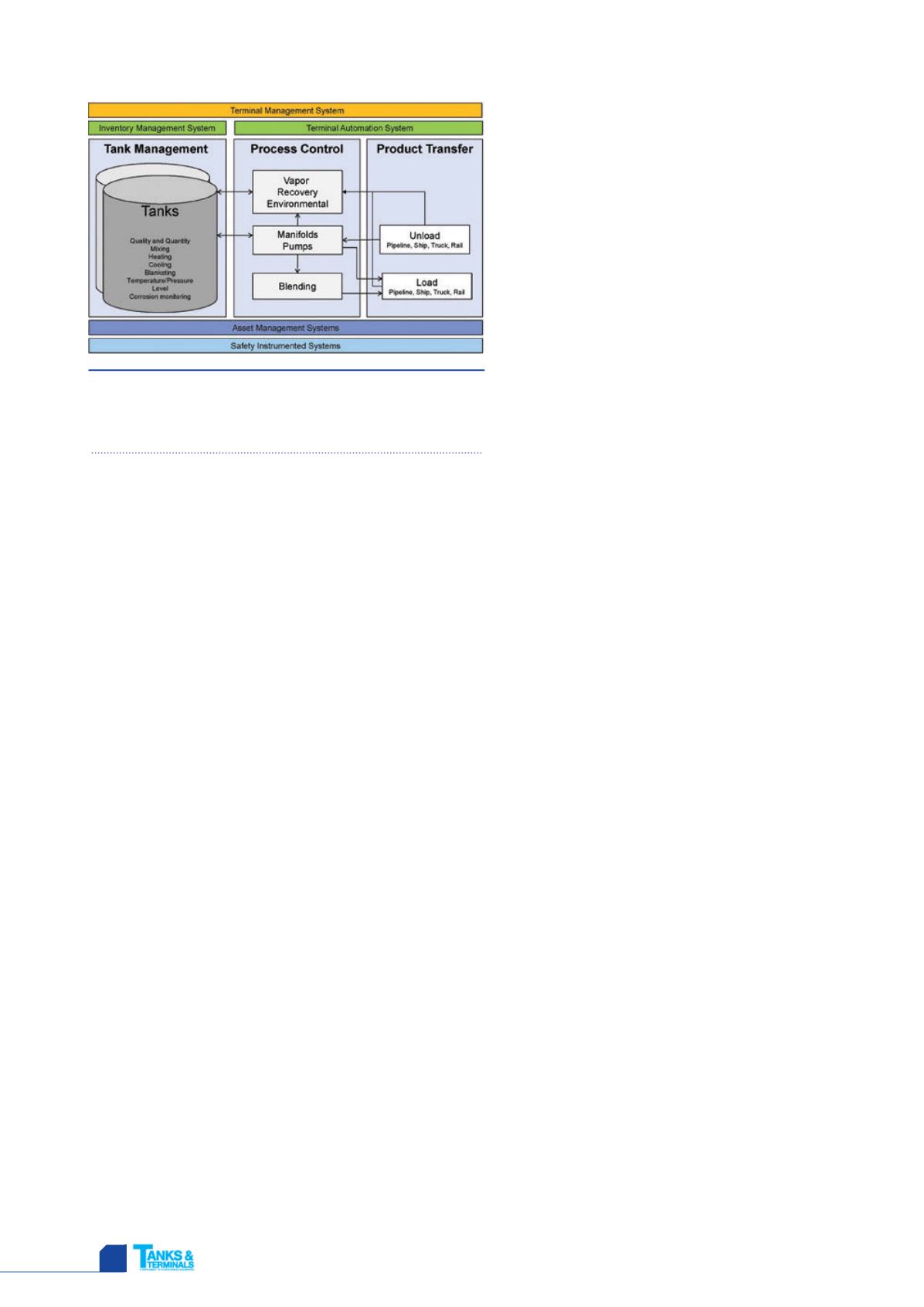

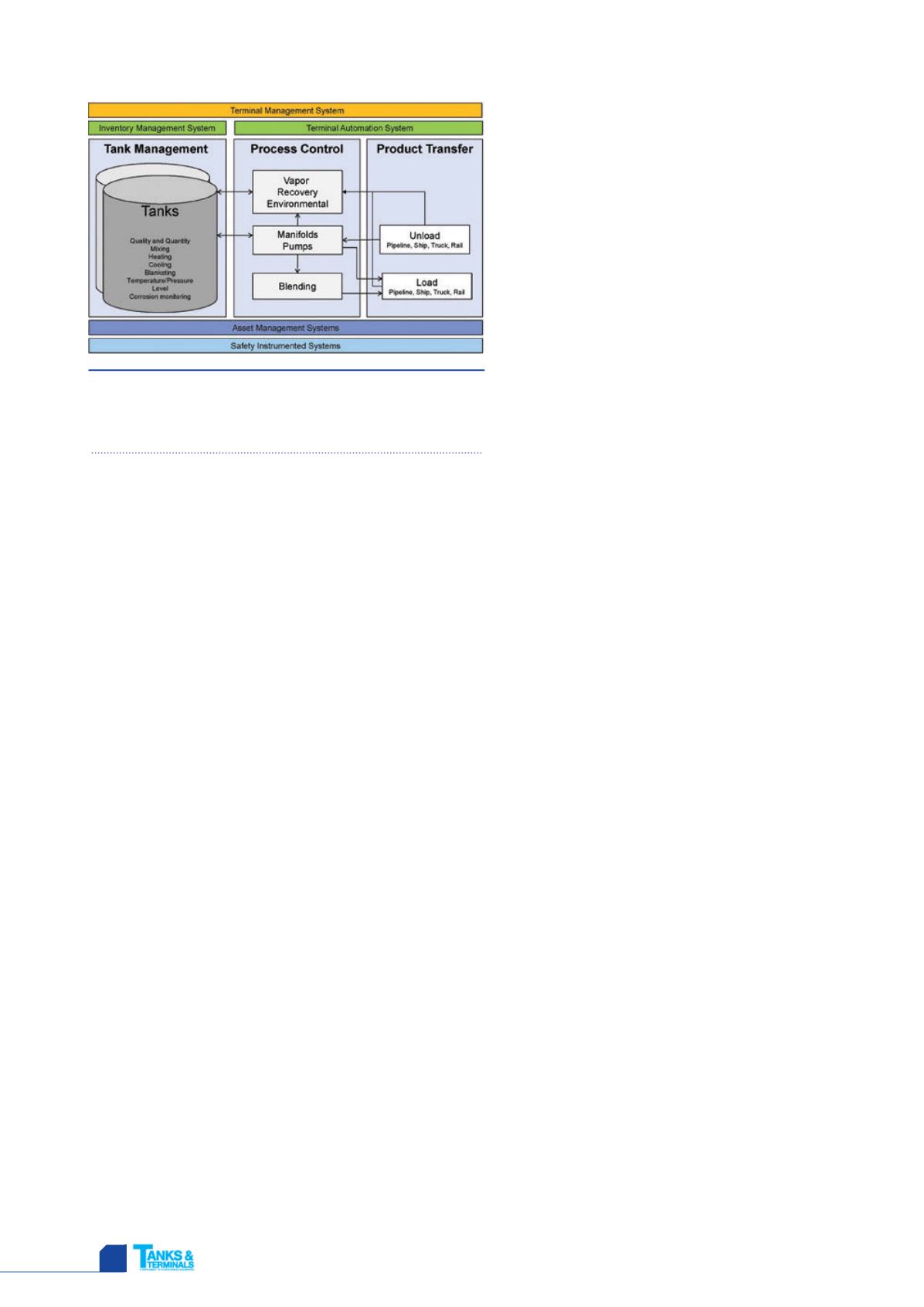

Terminal management covers all activities at a facility:

n

Inventory monitoring includes quality and quantity of

contents, heating or cooling if necessary, blanketing for fire

suppression, and corrosion monitoring to avoid leakage.

n

Process control encompasses movements, vapour recovery,

in tank actions, blending, and other processes required by

customers.

n

Asset management monitors the operation, utilisation and

condition of equipment including jetties, gantries, piping,

pumps, instrumentation and safety devices.

All of these capabilities have to work together flawlessly to

keep the operation performing at peak capability. A failed pump

motor or a leaking valve can prevent a critical lineup from being

implemented, delaying product movement or causing a spill or

contamination. Valves not closing fully can allow inventory loss

or products to mix, creating contamination issues.

An effective terminal automation system performs two major

functions. First, it has to be the terminal’s cash register and

bookkeeper, recording all flows in and out including custody

transfers and product movements. All the data comes from the

facility’s instrumentation through the process control system.

The second function is process control, monitoring and

operating all the valves, pumps, instruments and safety systems.

These two main functional areas may be supported on totally

separate platforms, but they must be integrated seamlessly

because information and data needs to constantly flow from one

to the other.

Product transfer and load out

In most cases, a terminal is not a consumer of products it

handles, at least not in any significant amounts. It makes money

Figure 2.

All the elements of a terminal operation, including

inventory management, are interrelated and perform

best when controlled by a seamlessly integrated terminal

management system.

by storing and moving product in and out, sending it

on to the final customer or the next processing phase.

Some products may be stored on the site for some

period of time, but in most cases, the less time in

storage, the better.

Many facilities have various pipeline connections

going in and out, along with the ability to load and

unload bulk carriers such as trucks and railcars, and, if

there is access via waterway, tankers and vessels. On

any given day product can be moving from any one of

those to any other causing a variety of challenges:

n

Custody transfer data must be accurate at all

times: all the products stored or moving through a

facility represent money, so the ability to know

exactly how much product is moving and its value

is paramount. Without the highest level of

measurement accuracy, recognised and accepted

by all sides, customers can contest the validity of

transactions.

n

Effective maintenance to keep pumps and valves

at peak performance: condition-based

maintenance is a critical part of asset management

because it can warn of developing problems while

there is opportunity to solve an issue before it

becomes an operational issue. Without such an

approach, maintenance becomes reactive instead

of proactive, either allowing outages to develop at

the worst times, or adding to costs due to wasted

efforts fixing things when not necessary.

n

Accurate and fast lineups permit more throughput

while avoiding inventory loss. Consider this

example: the contents of a vessel must be

unloaded to a tank near a jetty and then

transferred to a truck. If the terminal is large, those

two places could be several thousand metres

apart, and a dozen or more valves may need to be

set correctly to establish the proper lineup. With a

typical manual procedure, an operator needs to

walk through the lineup, checking or changing each

valve so it is in the correct position, and reporting

on each to the control room by radio. If the

operator is conscientious and qualified, this can be

an accurate and reliable procedure, but it could

easily take an hour or two, and if he or she makes

an error in valve identification, the result could be

disastrous. When valves are automated, they can

be controlled and monitored by the automation

system, allowing the correct lineup to be

established and verified in minutes. Lineups can be

stored in libraries, allowing them to be used

whenever needed, and special operations can be

verified to avoid safety incidents.

n

Broader ranges of products can be handled

without contamination: terminal operators

frequently cite operational problems caused by

increasing numbers of products. As product types

increase, so do opportunities for contamination.

Keeping product families and grades separate using

manual systems adds a level of complexity

difficult for operators to manage, whereas the task

is much simpler with automation.

n

Delays due to equipment failures can be minimised

or even eliminated: if a vessel pulls into the dock

and needs to be unloaded, the owner expects it to