HYDROCARBON

ENGINEERING

26

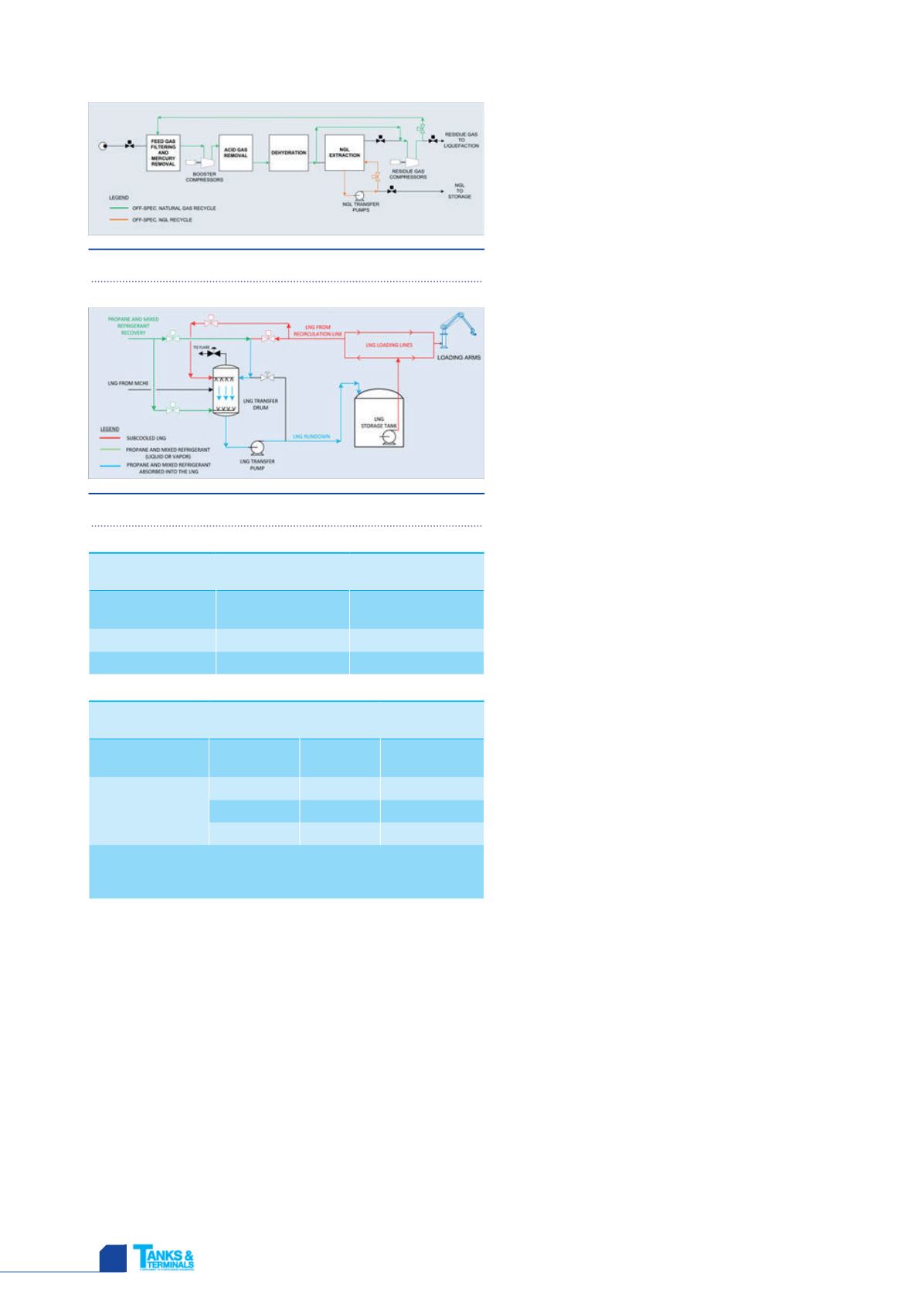

from the pipeline quality natural gas they receive for

liquefaction, so that such natural gas is capable of

being safely and effectively liquefied in the

liquefaction trains. CO

2

, water and heavy

hydrocarbons could freeze within the cold sections

of the natural gas liquids (NGL) extraction unit at the

PTF, or the downstream equipment at the LQF.

During startup activities, it is common practice to

flare off-specification gas until the correct

parameters of pressure and temperature are obtained

within the entire pretreatment train. This activity can

last several days. To prevent flaring off-specification

gas, the pretreatment trains include headers that will

allow the off-specification gas to be recycled in a

closed loop, not only during the startup phase but

also during operation, as shown in Figure 1.

Regenerative thermal oxidiser

A key part of the pretreatment facility is the acid gas

removal unit that eliminates CO

2

, H

2

S and other

undesirable contaminants from the natural gas to

make it suitable for the liquefaction process. These

contaminants are treated before being released into

the atmosphere. A regenerative thermal oxidiser

(RTO) from Eisenmann Corporation is used to remove

the volatile organic compounds (VOCs), including

aromatics with a minimum destruction removal

efficiency of 99% and 99% conversion of inlet H

2

S to

sulfur dioxide (SO

2

). The RTO is coupled with an

integrated scrubber and wet electrostatic

precipitator (WESP) to remove the SO

2

with a

minimum removal efficiency of 97.2% and particulate

matter to obtain the desired opacity in the exhaust

gas stream. Some sulfuric acid (H

2

SO

4

) mist will be

formed as part of the conversion process – this is

responsible for the visual plume in vents stacks.

Therefore, to stay within the stringent levels of

visible opacity in the waste stream, a dual field WESP

was added, resulting in an effective removal

efficiency that meets best available control

technology practices. An additional feature of the

RTO is the natural gas injection system with ultra low

NO

X

burner technology, which has 15% lower fuel

consumption in comparison with conventional

burners, and provides for reduced NO

X

emissions.

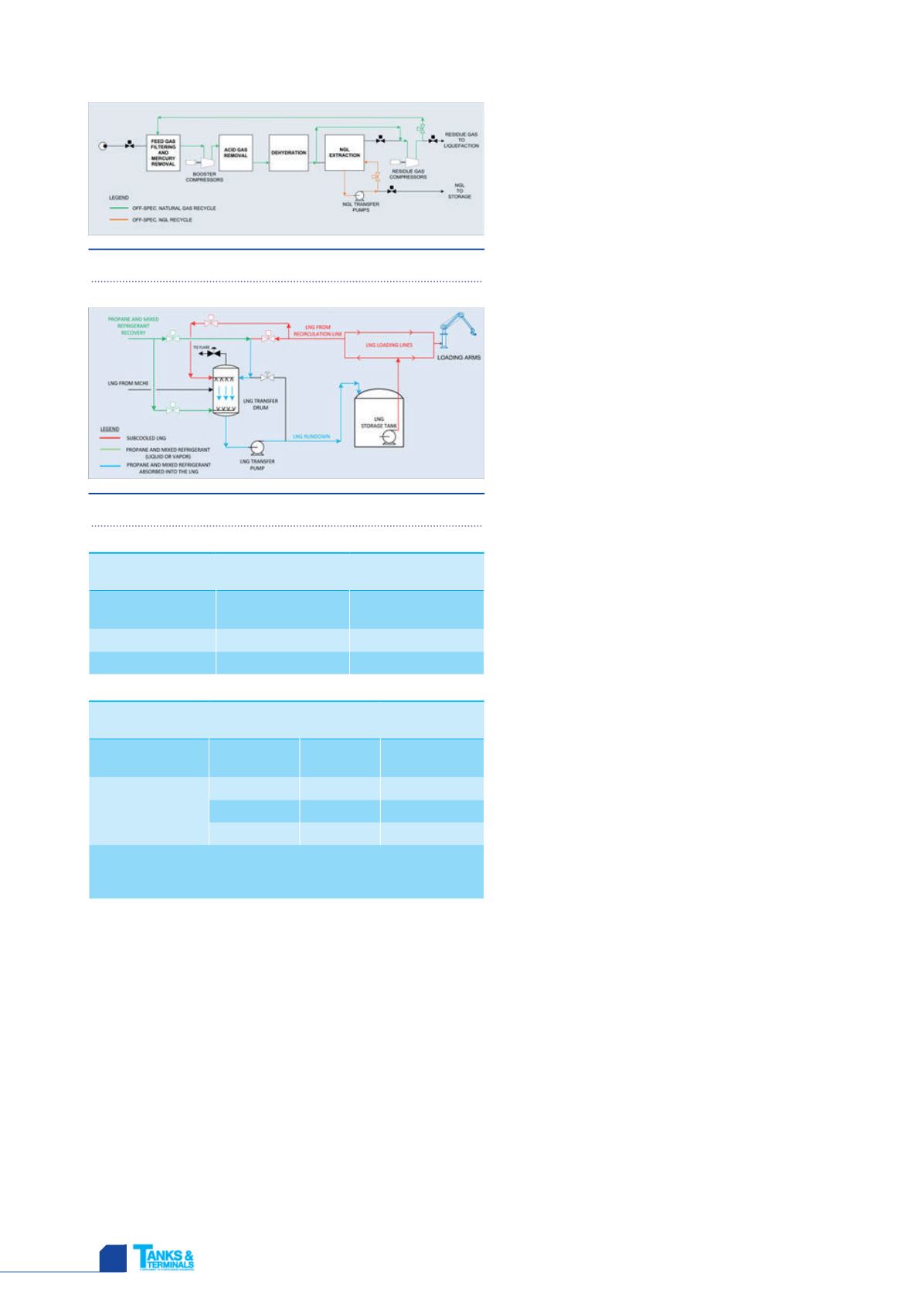

Recovery of propane and mixed

refrigerant

It is expected that during planned maintenance of

the main refrigerant compressors and other pieces of

equipment, it will be necessary to evacuate the

refrigerants from the liquefaction train to facilitate

safe maintenance activities. In the majority of the

existing liquefaction facilities, the mixed refrigerant is

flared and the propane is flared or recovered back to

storage.

The Freeport LNG liquefaction project

refrigerant recovery system is designed to inject

both vapour and liquid inventories of mixed

refrigerant (a multicomponent refrigerant with

Figure 1.

Simplified pretreatment facility block diagram.

Figure 2.

Propane and mixed refrigerant recovery concept.

Table 1.

Expected refrigerant recovered per

liquefaction train

Component

Liquid

(metric tonnes)

Vapour

(metric tonnes)

Mixed refrigerant

186

190

Propane

725

62

Table 2.

Estimated piping lengths and annual energy

savings

Area

Piping size

range (in.)

Length (ft)

Energy savings*

(kW-hr/y)

Liquefaction

6 - 8

4200

760 000

20 - 26

4000

1.3 million

Dock 2 LNG loading 26 - 32

9300

3.3 million

*Savings in compression power required to process the additional BOG

generated due to heat leak into the piping with conventional insulated

(foam insulation). VJP with vacuum level of 1 micron.

Island, utilising an existing dock (a second dock will be added as part

of the project), LNG storage (a third LNG full-containment tank will

be added as part of the project) and other equipment already in

operation. After the addition of the liquefaction capacity, the

terminal will still be able to operate in vapourisation and natural gas

send-out mode, if business conditions require it in the future.

Environmental stewardship is a standard of Freeport LNG’s

operations, and this has figured prominently during the design of

the liquefaction project. This article discusses some of the design

features that have been incorporated into the Freeport LNG

liquefaction project, with a twist of innovation that lessens the

impact on both the environment and the community.

Off-specification gas recycling capabilities

The pretreatment trains will be designed to remove

contaminants (CO

2

, H

2

S, water, heavy hydrocarbons and mercury)