HYDROCARBON

ENGINEERING

28

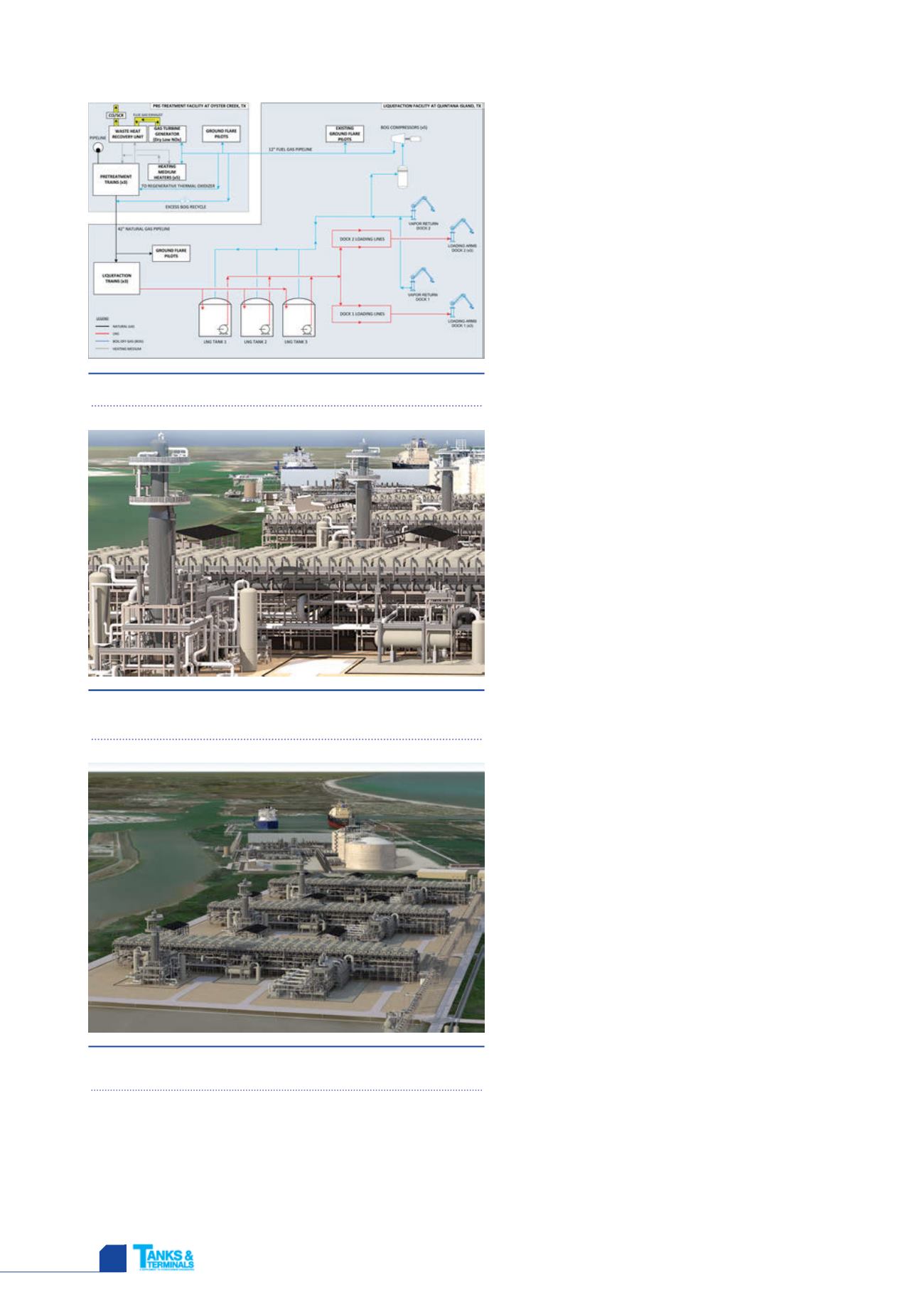

tanks. This recovery will greatly reduce the

emissions from the combustion of the propane and

mixed refrigerant in the ground flare. Figure 2 shows

how the refrigerants will be recovered by using the

subcooled LNG and by being mixed in the LNG

transfer drum before being pumped into the LNG

storage tanks.

The LNG transfer drum includes a spray

connection to help capture the vapour refrigerants

and to maintain the pressure in the drum during the

recovery operation. A sparger located at the

bottom of the drum facilitates the vapour recovery

and reduces the time and volume required to

dissolve the vapours into liquid.

During liquefaction mode operation, the LNG

transfer drum operates at near atmospheric

pressure, but during the recovery mode the drum

will operate at around 35 psig to facilitate the

absorption of the refrigerants into the LNG. Table 1

shows the expected amounts of refrigerant to be

recovered.

Vacuum-jacketed piping

LNG produced at the LQF trains flows through the

commonly called ‘rundown’ line to be stored in the

LNG storage tanks. From there it is pumped via the

loading lines to the docks. All these lines are being

designed as vacuum-jacketed piping (VJP).

VJP consists of a pipe-in-pipe system with a

vacuum in between for thermal insulation purposes.

The insulation performance of VJP is 10 times better

than conventionally insulated piping, which means

that the LNG remains cold for longer periods of

time, generating 10 times less boil-off gas (BOG),

which in turn creates energy savings. In addition, no

recirculation of LNG is required to keep the piping

cold between LNG ship loadings. Typical VJP

systems for LNG have an outer jacket made of

carbon steel, which is not rated to withstand the

temperatures and pressures from the LNG.

Freeport LNG upgraded all of its new VJPs with an

outer jacket of 304 stainless steel (the same as the

inner piping), which will prevent the LNG from being

released into the atmosphere upon a failure of the

inner piping. Piping bowing and the effects from

LNG jetting impingement in the outer piping were

taken into account during the design to ensure that

the outer jacket will not fail due to a malfunction in

the inner piping.

Table 2 shows the estimated piping lengths and

annual energy savings from implementing VJP

systems in the Freeport LNG liquefaction project.

Electric motors for main refrigerant

compressors

Three General Electric 75 MW variable speed

electric motors drive the low pressure mixed

refrigerant compressor, medium pressure and high

pressure mixed refrigerant compressors combined,

and the propane compressor.

Figure 3.

Boil-off gas recovery flow diagram.

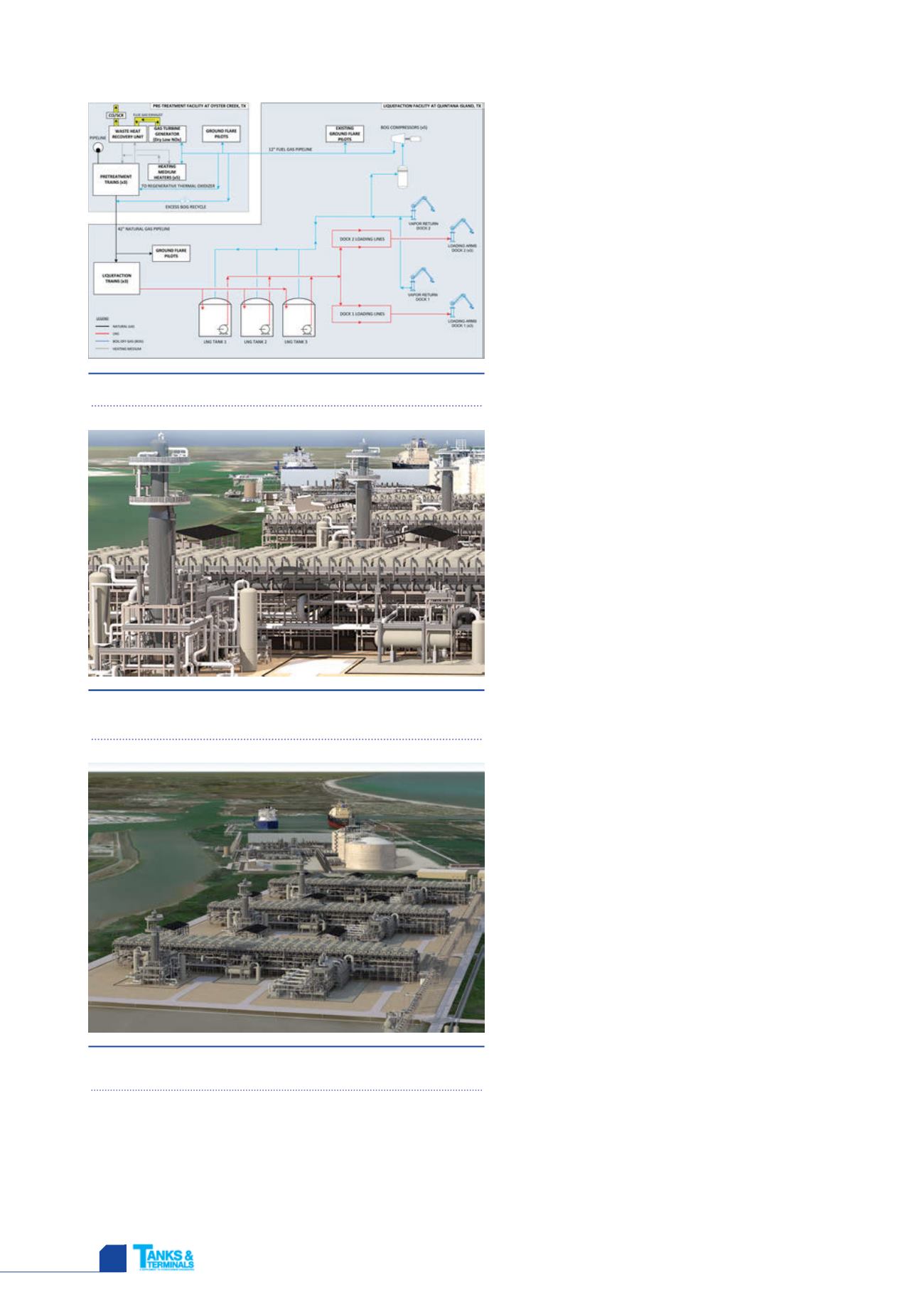

Figure 4.

Main cryogenic heat exchangers from APCI are the

tallest features of the LQF facilities.

Figure 5.

Overall 3D model rendering of Freeport LNG's LQF

facilities.

nitrogen, methane, ethylene and propane) and propane into the

LNG by using an LNG transfer drum, in which these fluids will

be absorbed by subcooled LNG. Freeport LNG liquefaction

trains feature a unique network of drains and vents that will

allow the collection of the propane and mixed refrigerant to be

injected into the LNG that will be stored in the LNG storage