HYDROCARBON

ENGINEERING

34

operation was being carried out in the pre-dawn hours of a Sunday.

Operators filling the tank did not realise the two level sensors on

the tank were both inoperative, nor were they paying close enough

attention to realise the tank was reaching its limit. Pumping

continued as the tank began to overflow, and leaks in the

surrounding retaining bund allowed the gasoline to flow

throughout the adjacent tanks. The resulting fire burned for five

days and destroyed most of the 194 000 t facility.

Elk River chemical storage facility

In January 2014, residents near Charleston, West Virginia, noticed

a strange odour from their drinking water and called local

authorities. The odour was caused by

4-methylcyclohexylmethanol leaking from the Freedom

Industries chemical storage facility near the Elk River, the source

of the drinking water. The chemical, used to clean coal in nearby

mining facilities, was leaking out of a 1 in. hole in the bottom of a

40 000 gal. tank. Approximately 7500 gal. escaped, and much of

it found its way through the facility’s containment system to the

nearby river, where it affected the water supply of 300 000 local

residents.

Jaipur oil terminal

In October 2009, Indian Oil Corporation was beginning to

transfer gasoline from a storage tank to a pipeline at its Sitapura

Oil Terminal near Jaipur, India. Operators apparently opened

valves in the wrong sequence, resulting in a major discharge that

continued for hours. Gasoline accumulated around the tank and

created a cloud of vapour making breathing difficult, but the

facility had no incident response plan to deal with such a

situation. Eventually the vapour found an ignition source and a

massive explosion ensued. Ultimately the incident claimed

11 lives and injured more than 150.

Methods for prevention

Each of these situations could have been prevented by effective

automation. Buncefield was largely an instrumentation and

safety instrumented system (SIS) failure, and the situation was

made worse because operators had inadequate operator

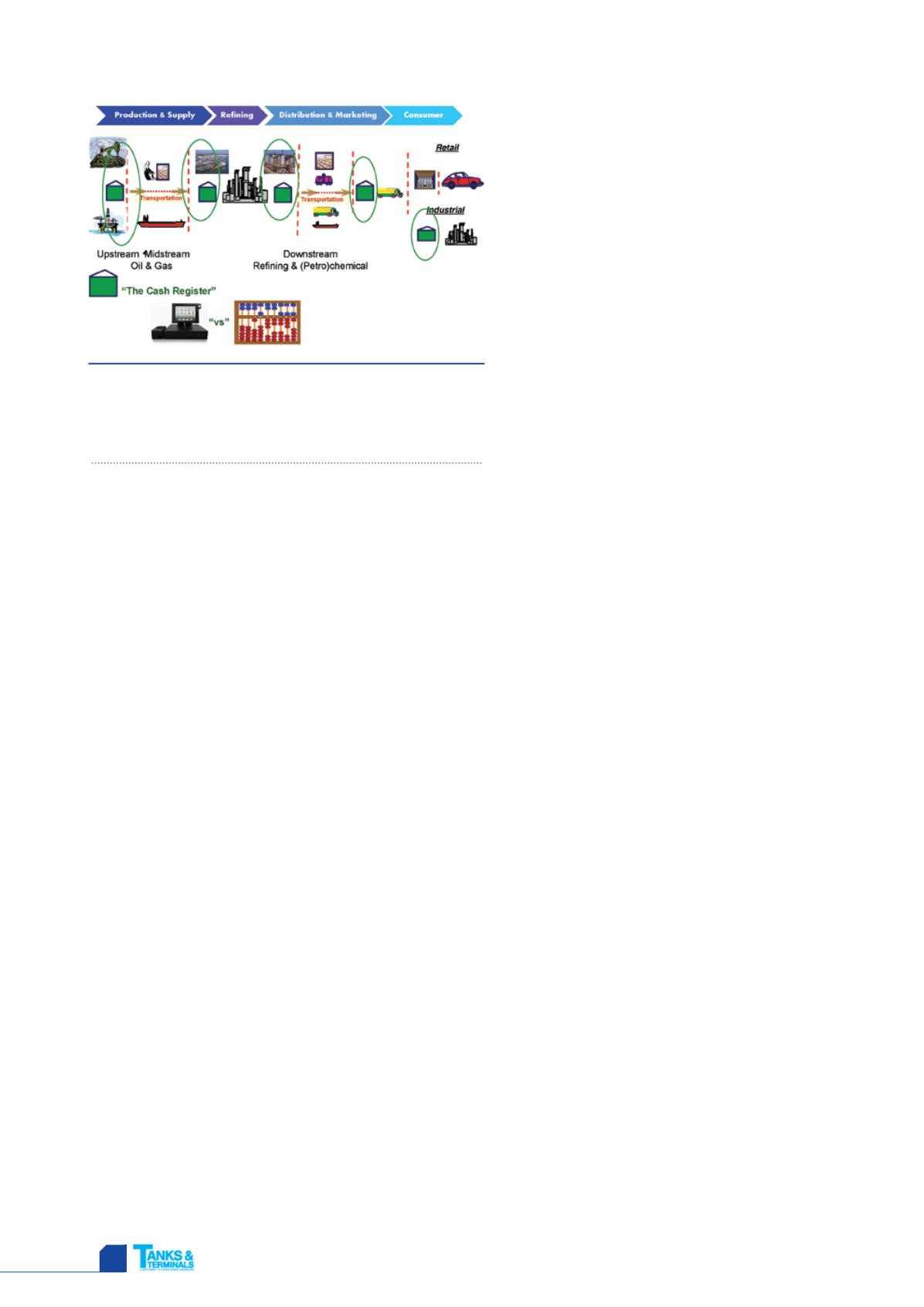

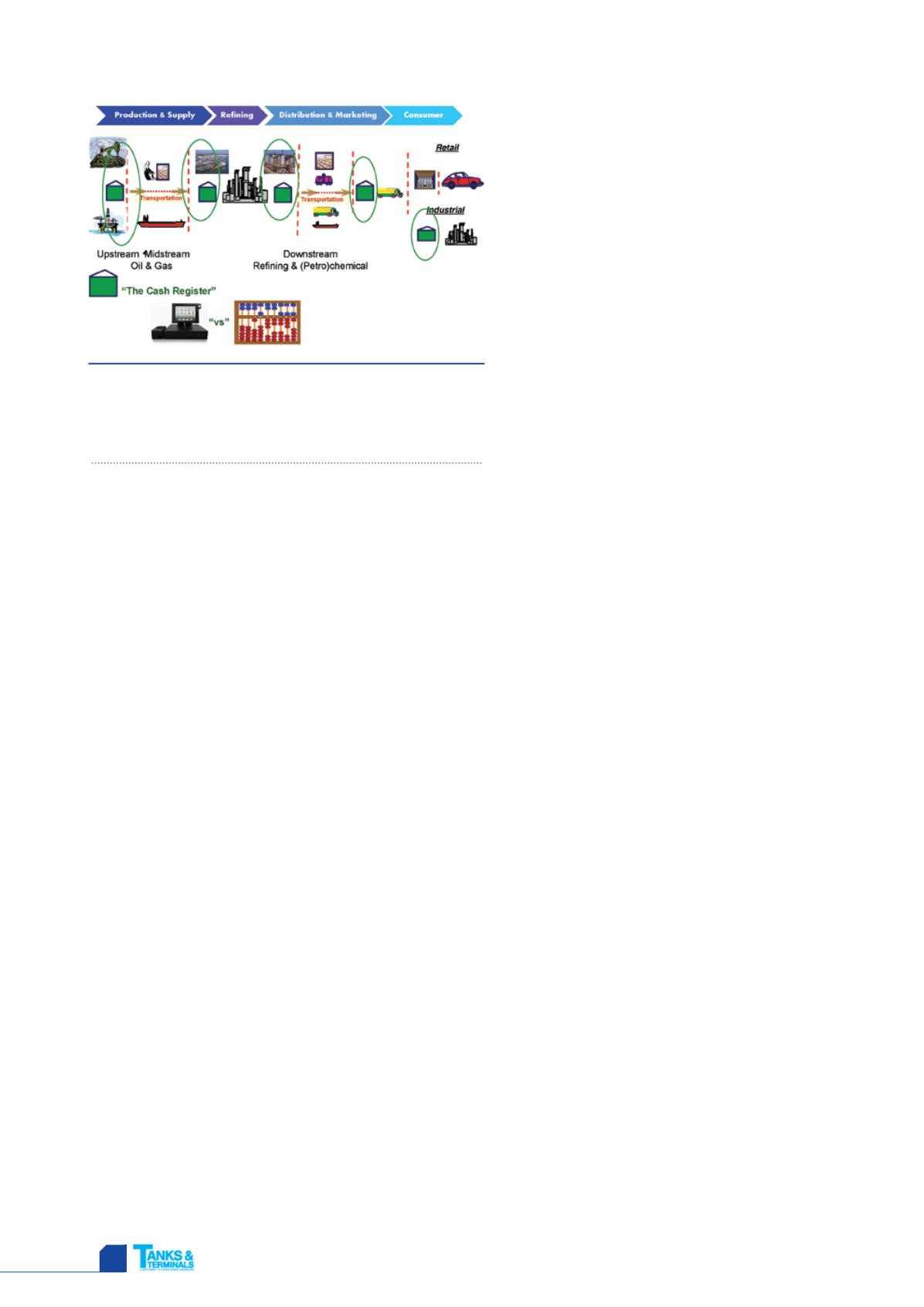

Figure 1.

The global hydrocarbon supply chain is arguably

the most valuable and pervasive transfer activity in the

world. Terminals enter into the process time and time again

as product is processed and moves from wellhead to final

consumer.

interfaces to see what was going on throughout the

facility. Appropriately selected level sensors

integrated with more informative operator interfaces,

and an effective SIS, would have stopped the tank

from overfilling, whether the operators were paying

attention or not.

Freedom Industries had inadequate leak detection

capabilities, so neither its operators nor its safety

systems were able to realise the contents of a tank

had decreased substantially without any reason.

Inventory management capabilities tied to the larger

automation system could have detected such

changes, and leak detection sensors would have

identified the chemical outside its tank.

The Jaipur facility depended on human operators

to establish piping lineups, opening and closing

manual valves in the correct sequence to direct

products to the right locations. With automatic valves

controlled by an automation system, the valve lineup

procedure would be performed properly every time.

Positive effects of automation

Automation is not simply a defensive strategy to

prevent incidents; it can also increase the amount of

product a given terminal can handle while reducing

costs (Figure 2).

The challenges tank farm and terminal operators

face these days can be separated into four main areas:

n

Product issues, including inventory loss and

contamination: the number of products most

terminals have to handle has increased in recent

years, increasing the number of changeovers, tank

cleanings and line clears.

n

Customer demands: terminal users, whether

internal or external customers, expect more in the

way of product processing capabilities,

administrative information and turnaround speed.

Data on custody transfer has to be flawless and

delivered immediately to facilitate rapid order to

cash.

n

HSSE demands: every safety and environmental

incident at a terminal anywhere in the world

seems to drive tighter operational restrictions,

and operators must respond.

n

Personnel and staffing challenges: terminal

operators are not immune from the common

industry problem of finding reliable, technically

qualified workers. The great shift change affects

everyone.

Terminal management

Terminal owners and managers want control of the

business aspects of their operations, and these

activities centre on inventory tracking and handling

speed of both product and information. Moving

product through the facility is what generates

income, and movements need to be measured very

precisely.

n

Sophisticated instrumentation, such as the

Rosemount 5900S high precision radar gauge,

keeps a close handle on product movement,