are primarily used in Russia. Their characteristics, as well as the

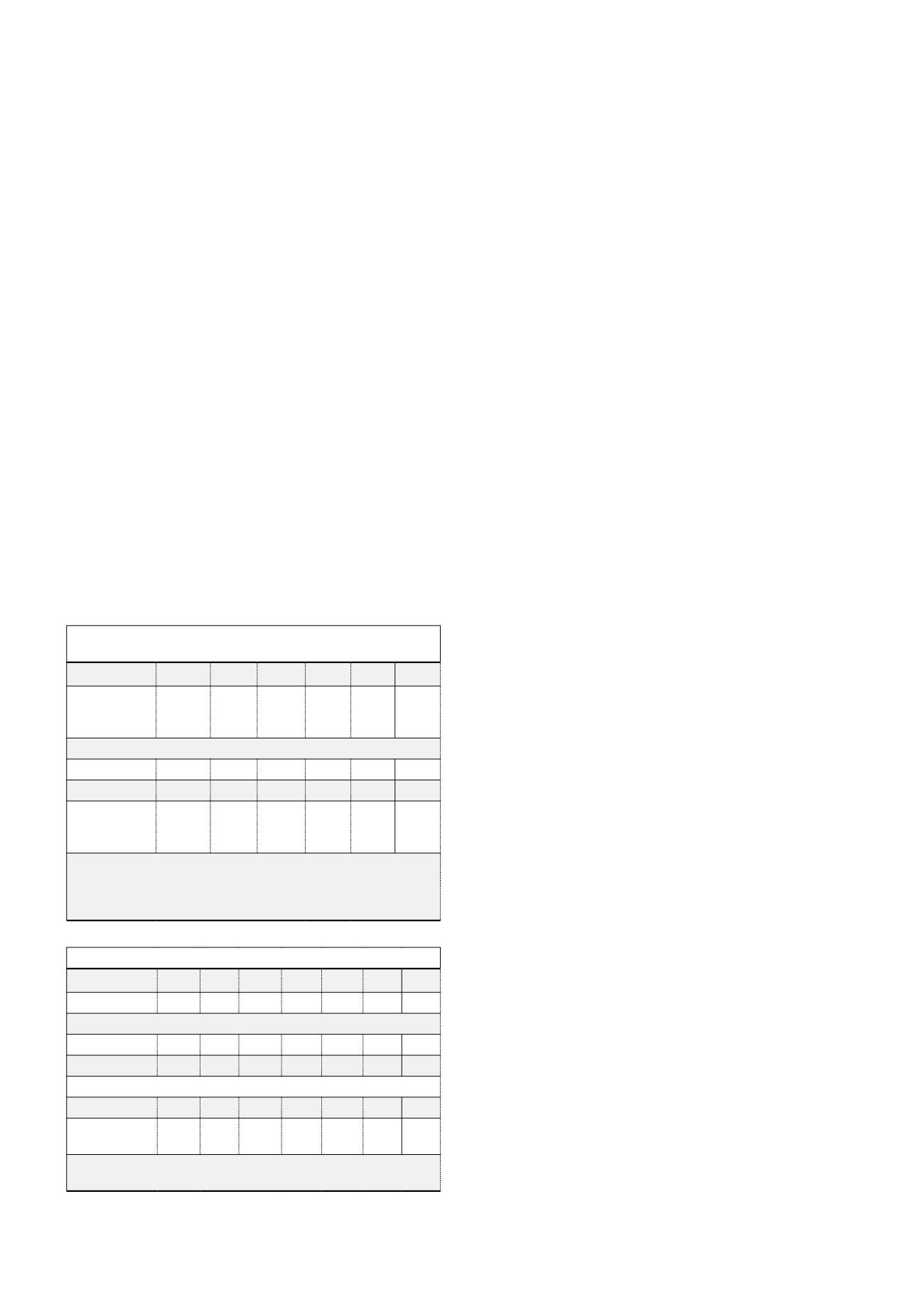

length of oil pipelines, are given in Table 1.

The countries that have the largest lengths of operating oil

pipelines are the USA (85 000 km), Western European countries

(35.3 000 km) and the Organisation of the Petroleum Exporting

Countries (OPEC: approximately 20 000 km).

1

Pipeline transport

accounts for almost half of the total freight turnover in Russia.

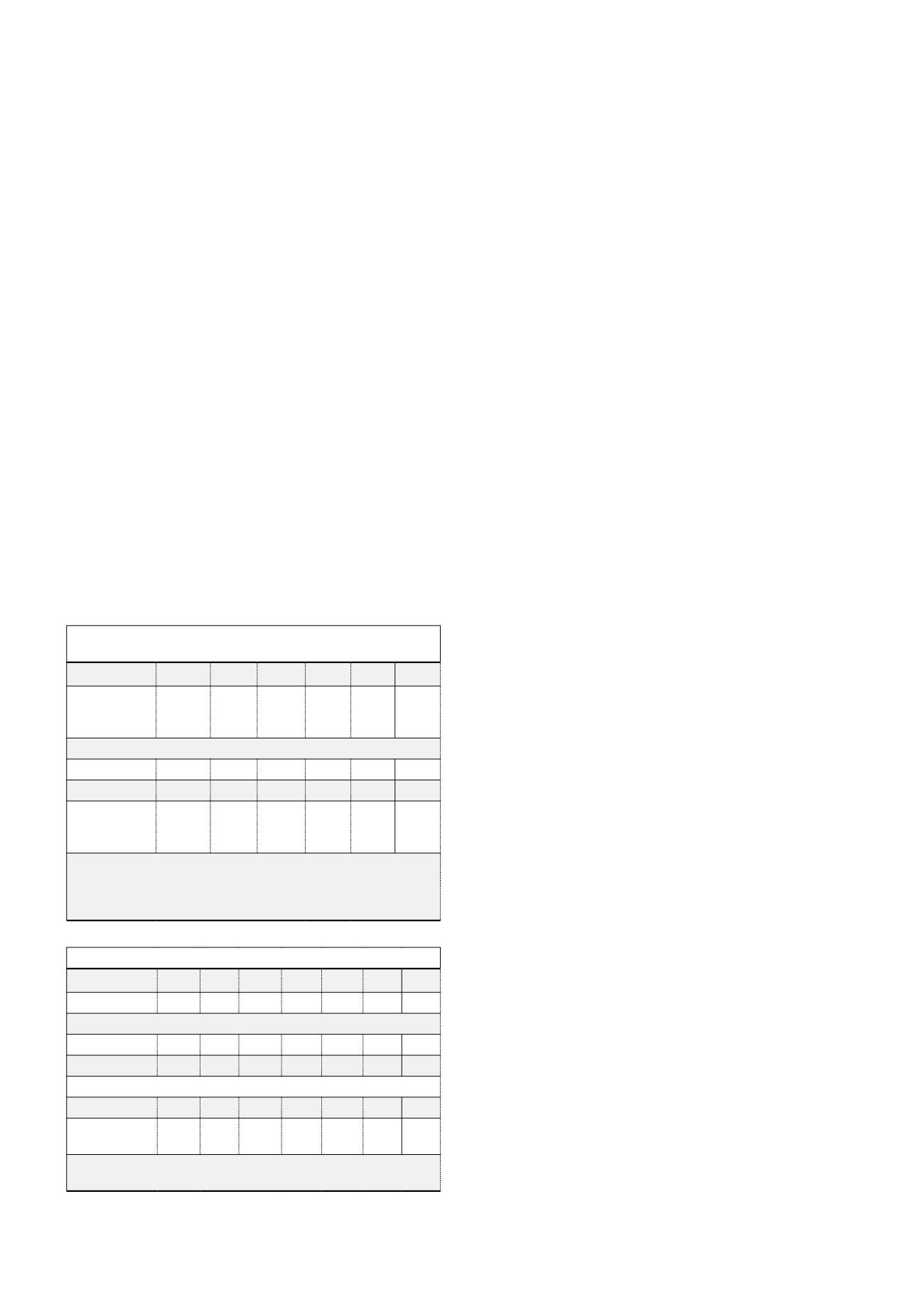

Despite the fact that the volume of gas transmission

decreased in 2012 and 2013, gas transmission’s trunk pipeline

freight turnover numbers were higher than those of oil or

petroleum products (Table 2).

In the USA, oil pipelines transmit three quarters of the total

oil transported through the country, whereas in Russia this

number is considerably higher (Table 3).

2

Operating in Russia

The largest operator for the oil-trunk pipelines in Russia is oil

transporting joint-stock company Transneft. This company

transports 93% of the oil extracted in Russia and owns more

than 500 pumping stations and 22 million m

3

of storage

capacity.

Natural gas produced in Russia is pumped into gas

trunklines. These trunklines are integrated into the Unified

Gas Supply System (UGSS) of Russia that is owned by public

joint stock company (PJSC) Gazprom. The UGSS is the world’s

largest gas transmission system. It is a complex that consists

of facilities for extraction, processing, transmission, storage

and distribution of gas. It comprises of 170 700 km of gas

trunklines and branches, 250 compressor stations with 3825

gas compressor units totaling 461 million kW in capacity and

26 underground gas storage (UGS) facilities, with the aggregate

active capacity of 71.1 billion m

3

.

3

More than half of the length of the UGSS is gas pipelines of

large diameter (approximately 1220 and 1420 mm). The average

distance of gas transmission to Russian consumers is 2785 km

and 3430 km to external consumers.

Underground gas storage (UGS) facilities are an

indispensable part of the Unified Gas Supply System of Russia

and are situated in the main gas consumption regions. UGS

facilities allow specialists to control seasonal fluctuations

of gas demand, reduce peak loads in the UGSS and provide

flexibility and reliability of gas supply. The network of UGS

facilities supplies Russian consumers with over 20% of total

gas volumes during the cold season when heating is necessary

and sometimes over 30% during sharp cold spells. There are 25

underground storage facilities in the Russian Federation with

the total operating gas reserve of 65.2 billion m

3

of gas.

4

Centralised control and considerable ramifications with

parallel transmission routes of the UGSS provide a substantial

reliability margin and ability to secure uninterrupted gas supply

even under peak season loads.

The importance of trunk pipelines

How strategically important a trunk pipeline is determines the

requirements for its technical condition. Although a substantial

margin of operational reliability is taken into consideration

when the trunk gas pipelines are being designed, age-related

transformations are the primary factors that determine the

strength parameters of trunk pipelines. The main bulk of Russian

trunk oil pipelines (73%) were constructed more than 20 years

ago.

5

Today, depreciation of all trunk pipelines exceeds 60%.

Almost half of the trunk oil pipelines are close reaching the end

of their amortisation period – 30% of oil pipelines have been in

operation for over 33 years and 37% have been in operation for

20 - 30 years.

6

However, an older age of a pipeline does not automatically

lead to putting it out of operation. Transneft, in conjunction

with scientists, has carried out a considerable amount (even by

the academic science standards) of experimental work on pipe

steel that has been in operation for over 25 years in order to

study the connection between age of pipelines and failure rate.

More than 370 pipe samples and about 3000 standard samples

of a pipe metal were tested during a period of six years. The

results of cyclic bench tests showed that the samples sustained

pressure that was stronger than of that applied during the tests

at manufacturing plants. Deformation ageing of pipeline metal

and degradation of its mechanical properties appear only in

certain sections of the pipes that have been in operation for

more than 25 years. These are the sections that have spots of

high pressure concentration that are caused by defects in the

pipe walls or welding. After the defects have been detected

Table 1. Total length of pipelines in Russia (year end, thousand

km)*

1990 2000 2005 2010 2011 2012

Trunk

pipelines –

total

212

215 225 233 242 250

Including:

Gas pipelines 144

152 160 168 171 175

Oil pipelines 52

48

50

49

51

55

Petroleum

product

pipelines**

15

15

16

16

20

* Source: Russia’s 2014 Statistical Pocketbook. Rosstat, Moscow –

Table 17.23.

** From 2011 – including the length of petroleum product trunk

pipelines in foreign states.

Table 2. Freight turnover by trunk pipelines (billion t - km)*

1990 2000 2005 2010 2011 2012 2013

Freight – total

2575 1916 2474 2382 2422 2453 2513

Including:

Gas

1335 1171 1317 1259 1302 1265 1289

Oil freight

1240 745 1156 1123 1120 1188 1224

Including:

Oil

1198 718 1123 1084 1083 1152 1182

Petroleum

products

42

27 33

39 38 36 42

* Source: Russia’s 2014 Statistical Pocketbook. Rosstat, Moscow –

Table 18.11.

20

World Pipelines

/

MARCH 2016