handover stage, however, working in a consistent,

standardised cloud environment would all but

eliminate such issues.

What is the industry doing?

Despite the advantages, the industry has been slow to

embrace cloud. There are two main reasons for this:

n

Risk aversion: the process industries are highly

regulated and competitive, with a natural aversion to

risk. The tendency is to ‘wait and see’ how a new

technology plays out in another industry before

adopting it.

n

The gap between technology and knowledge: for a

long period, there was a shortage of cloud providers

with comprehensive knowledge of the process

industry requirements. After continuous development

and pilot projects with the key players in the industry,

cloud solution providers have breached the gap and

know not just their technology, but recognise its

specific applications in the process industries.

Success in the cloud

Intergraph’s SmartPlant® Cloud is an example of a cloud

solution for a business issue. It is more than just another

cloud offering, it is a business enabler that brings globally

dispersed resources together. The solution has been

adopted by owner operators and EPC contractors, as well

as by service providers, such as project management

consultants. Major players such as Eni Process S.p.A., Fluor

Corporation and Shell have successfully executed

projects in the cloud, proving that not only can it be

carried out, but that there are significant advantages in

terms of efficiency and access to information. These

companies are now using SmartPlant Cloud to get the

best from their data and use it efficiently, without

significant investments in information technology (IT).

Under the current market conditions, this is what is

required to reduce costs and compress schedules while

improving safety.

Burns and McDonnell, an American engineering design

firm, has also implemented SmartPlant Cloud. The company

noted two key benefits to this technology. The first is the

application expertise, both in terms of the backend database

administration and in the Intergraph application itself, which

aided greatly in setup and maintenance. The second is the

speed of onboarding. Intergraph worked closely with Burns

and McDonnell's internal experts to address any issues,

which meant a complex product could move into

production more efficiently.

Conclusion

As global energy demands increase and the oil price

continues to fluctuate, it is becoming increasingly clear

that a major focus must be placed on the minimisation of

overheads, while an even sharper focus on productivity

and costs is needed to achieve this. Implementing cloud

technology today will be best placed to embrace these

challenges.

References

1. TechValidate. TVID: 19F-FA4-8B6, BE6-0AE-404, 600-87E-B0C.

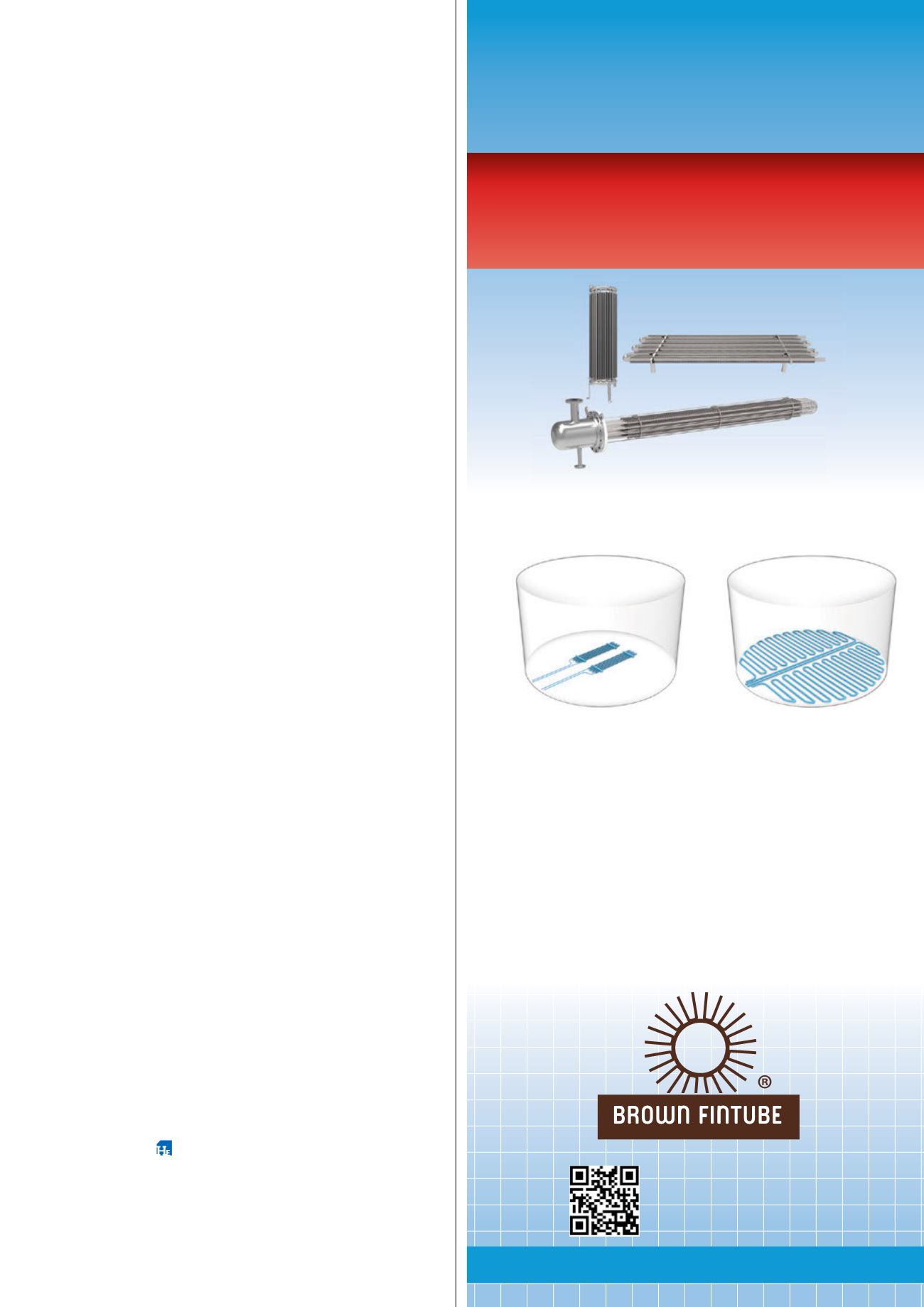

BROWN FINTUBE

®

ADVANCED

TANK HEATER

TECHNOLOGY

Heat MORE for

LESS with our

compact designs!

· Reduced Capital and Operational Costs

· Better heat distribution

· Less fluid displacement

· Decreased coking

Our product can offer:

For related trademark

information, visit:

Available from stock

· Sulfur

· Asphalt

Ideal for:

· Caustic

· Lube oils & more!

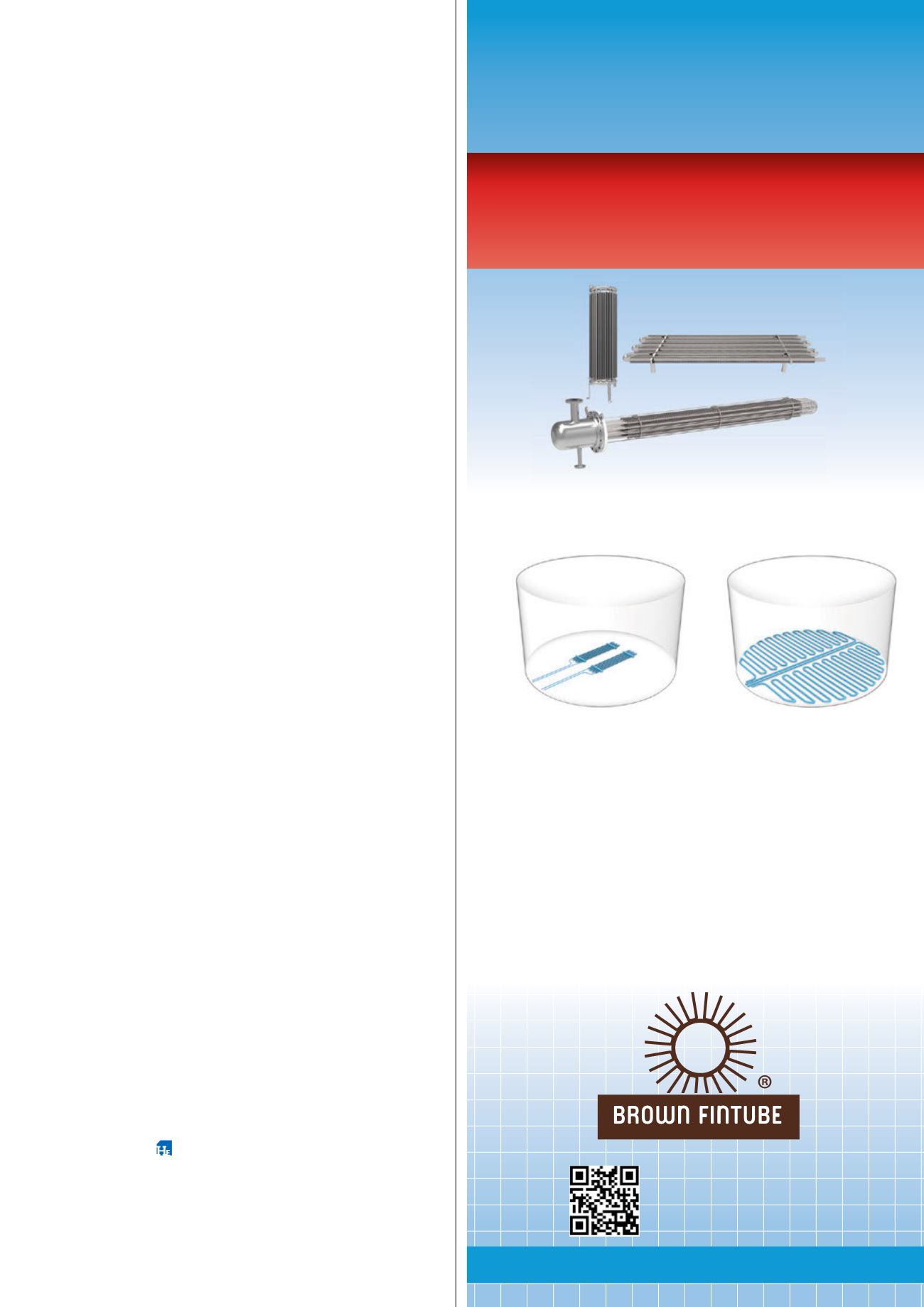

TF

HL

MTH

Less Effective

Conventional

Method

Horizontal

BROWN FINTUBE

®

Tank Heater Configuration