June

2016

HYDROCARBON

ENGINEERING

38

EPA CAA: a historical perspective

The CAA of 1963 and subsequent changes in 1970, 1977, and 1990

demonstrate efforts by the US to control and reduce air pollution. The

CAA of 1963 was the first federal legislation aiming to control air

pollution. An expansion in 1970 led to the development of federal and

state regulations and was followed by the establishment of the EPA in

1971.

Major amendments to the CAA were implemented in 1977 for the

Prevention of Significant Deterioration (PSD) in specified areas with

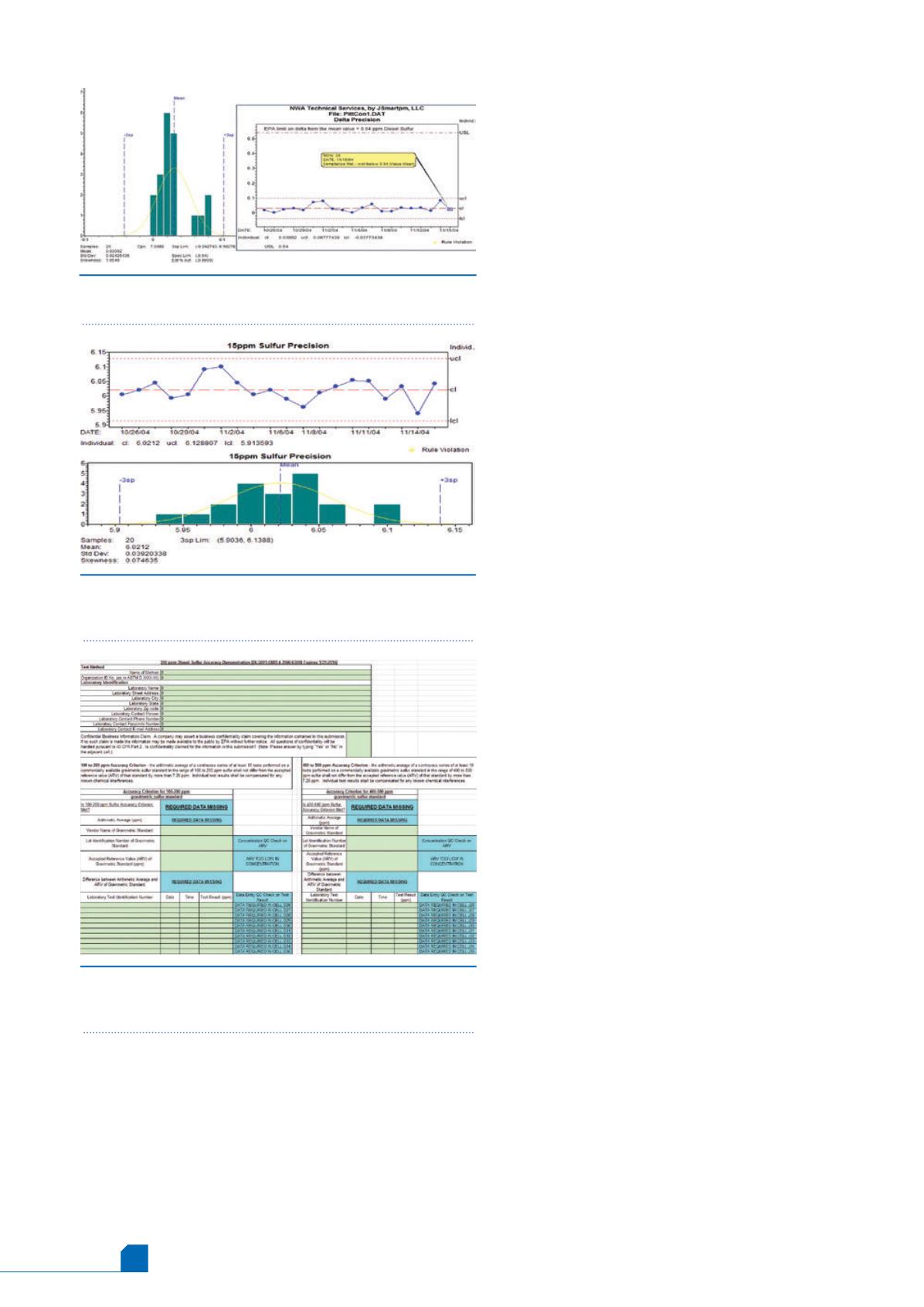

Figure 1.

Historical data – PBATMA regulations require that

AC/CA data is stored for five years for review and analysis.

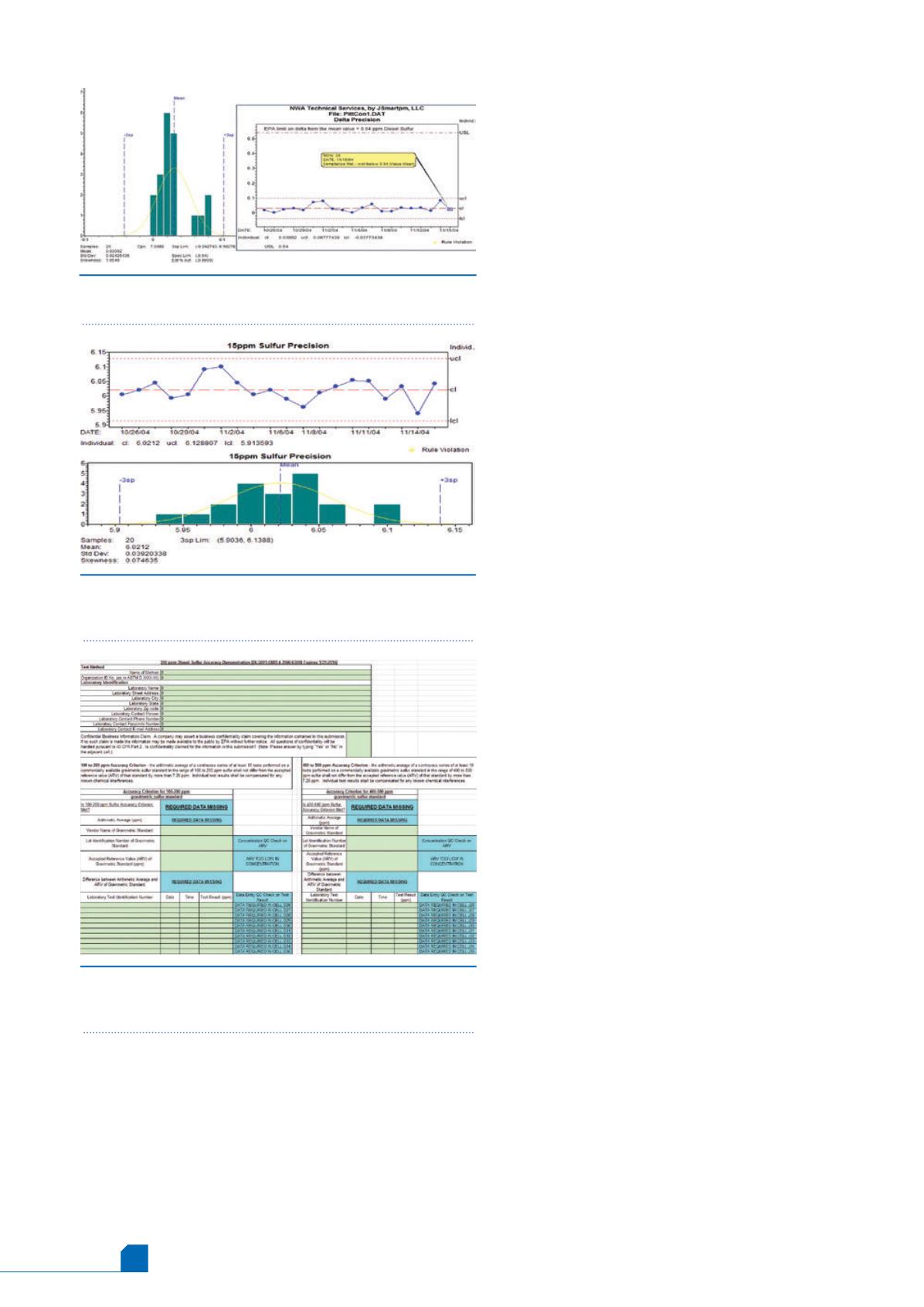

Figure 2.

Refineries are required to monitor and adjust their

control limits if the new calculated limits are statistically,

significantly different from the existing limits.

Figure 3.

EPA sulfur test method spreadsheet – the EPA

offers a sulfur test method spreadsheet for diesel that can

be adapted for expanded applications.

5

separate requirements for ‘non-attainment’ areas that could not

meet federal air quality standards (National Ambient Air Quality

Standards [NAAQS]). In 1990, further amendments included

increased authority at the federal level. This series of

amendments addressed acid rain, ozone protection, increased

enforcement, and an expansion of research.

Fuel refineries experienced multiple milestones, including

the reduction and ultimate elimination of lead-based additives

and the reformulation of gasoline for cleaner burning motor

fuels. The article, ‘Clean by Design’, discusses the increased

standards for clean fuel manufacturing.

1

Clean fuels compliance

has deeply affected quality control (QC) standards. Attention to

the accuracy of data has grown exponentially since the CAAwas

established, with a significant increase in expectations this year.

Stringent guideline changes

PBATMA provides guidelines to ensure the accuracy and

precision of data generated by fuel refineries. In the past, data

quality was deemed acceptable based on industry

recommendations with minimal statistical analysis, but PBTAMA

requires tracking and reporting specific precision and accuracy

parameter variations.

Effective from January 2016, the Tier III regulations expanded

to require heightened certification testing with defined test

method compliance criteria. Every batch of motor fuel must be

systematically tested to prove that the material is suitable and

data must be collected in such a way that specific results can be

reported to the EPA.

In the past, testing methods were regulated but monitoring

precision and accuracy was left up to individual laboratories.

Approved testing methods were tracked by version number.

Federal regulations required labs to use outdated methods for a

period of time when the regulations were not updated as

quickly as the new lab methodology. The introduction of the

PBTMA has addressed these issues with regulations regarding

the performance of tests, according to published methodology

and demonstration of the quality of data. Each parameter

(vapour pressure, etc.) for a batch of gasoline must be within

specifications and test method precision, and accuracy must be

properly demonstrated or the product cannot be released to

commerce.

Refineries must track details of laboratory organisation,

ambient temperatures, humidity and other important

parameters.

Regulatory compliance: staying on top

of the details

Because the CAA is the precursor to many environmental laws,

and has seen great change since it was initiated in the 1960s, the

documents outlining regulatory compliance are often updated.

Details of regulatory compliance, reporting and records

management are located in the Code of Federal Regulations

(CFR).

2

It is important to note that the CFR is a living document

with a procedure for change. In the author’s opinion, it is always

best to use the official government electronic format of the

code when obtaining details to ensure that they are current. The

government provides a website (eCFR) where the current code

can be found.

3

It is also important to note that the storage of data is critical

for compliance. Assignable cause/corrective action (AC/CA)