June

2016

HYDROCARBON

ENGINEERING

30

which are connected to the flare, it may be prudent to

specify the maximum back pressure at the process unit

battery limit when sizing the outside battery limits (OSBL)

headers and sub-headers from various units in the complex.

This would enable the unit engineer to size his or her

network independently and later integrate the same, along

with the OSBL relief network. This approach is slightly

conservative, yet effective when there are several different

entities, or offices, involved in the design of a complex relief

network, which involves many process units. For the

preliminary sizing of the inside battery limits (ISBL) relief

network, a maximum back pressure of 1.5 kg/cm

2

g at the

unit battery limit could be used (assuming that balanced

bellows PSVs are used at lower set pressures, and

accounting for the pressure losses for the liquid seal drum,

gas seal and flare tip). Further optimisation can be targeted

once all the relief valve data and pipe lengths, based on the

final piping isometrics, have been entered in the flare model

for the complete system.

n

n

Actual length of flare headers and sub-headers: the sizing

of the relief network should be based on the actual

routing and configuration of the PSV laterals, sub-headers

and main flare header. One of the most important factors,

which has a pronounced impact on the back pressure, is

the piping expansion loop configuration, which is based on

the design temperature of the flare header. Each piping

expansion loop would result in four additional 90˚ bends,

some additional straight length, and the exact

configuration of the expansion loops on the main

header/sub-headers, which could lead to a huge increase

in the built up back pressure, especially in cases involving

high pipe diameters. This needs careful attention when

designing a new relief network. The normal practice is to

specify a single design temperature for the entire length of

the OSBL flare header(s); however, sometimes this results

in a highly conservative expansion loop configuration,

leading to increased back pressure and cost. To optimise

the number of expansion loops, a flare header

temperature profile can be generated based on the actual

heat lost from the hot flare header to the ambient. Based

on this temperature profile, a lower flare header design

temperature can be specified for those OSBL header

sections farther away from the process unit(s), which

would lead to a smaller number of piping expansion loops,

thus lowering overall cost. Close coordination with the

piping stress engineer is required to make this exercise

effective.

n

n

Allowance for the pressure drop in the liquid seal drum

(where provided): the liquid seal drum should, generally, be

included in the scope of the flare vendor, as most of the flare

vendors provide their own specialised liquid seal drum

designs (including the specification of the proprietary drum

internals, e.g., anti-slosh baffles, etc). Generally, around

0.2 - 0.25 kg/cm

2

is considered adequate for the liquid seal

drum when sizing a new relief network.

Flare knockout drum and pumps

An adequately sized OSBL flare knockout drum should be

provided in order to prevent the carry over of liquid droplets

to the flare stack. The sizing of the knockout drum should

consider all the major relieving scenarios in the complex. In

situations involving extremely high peak flare loads, the

possibility of providing two parallel knockout drums, with

symmetrical inlet piping, could be explored. On a large

diameter horizontal knockout drum, the inlet header may be

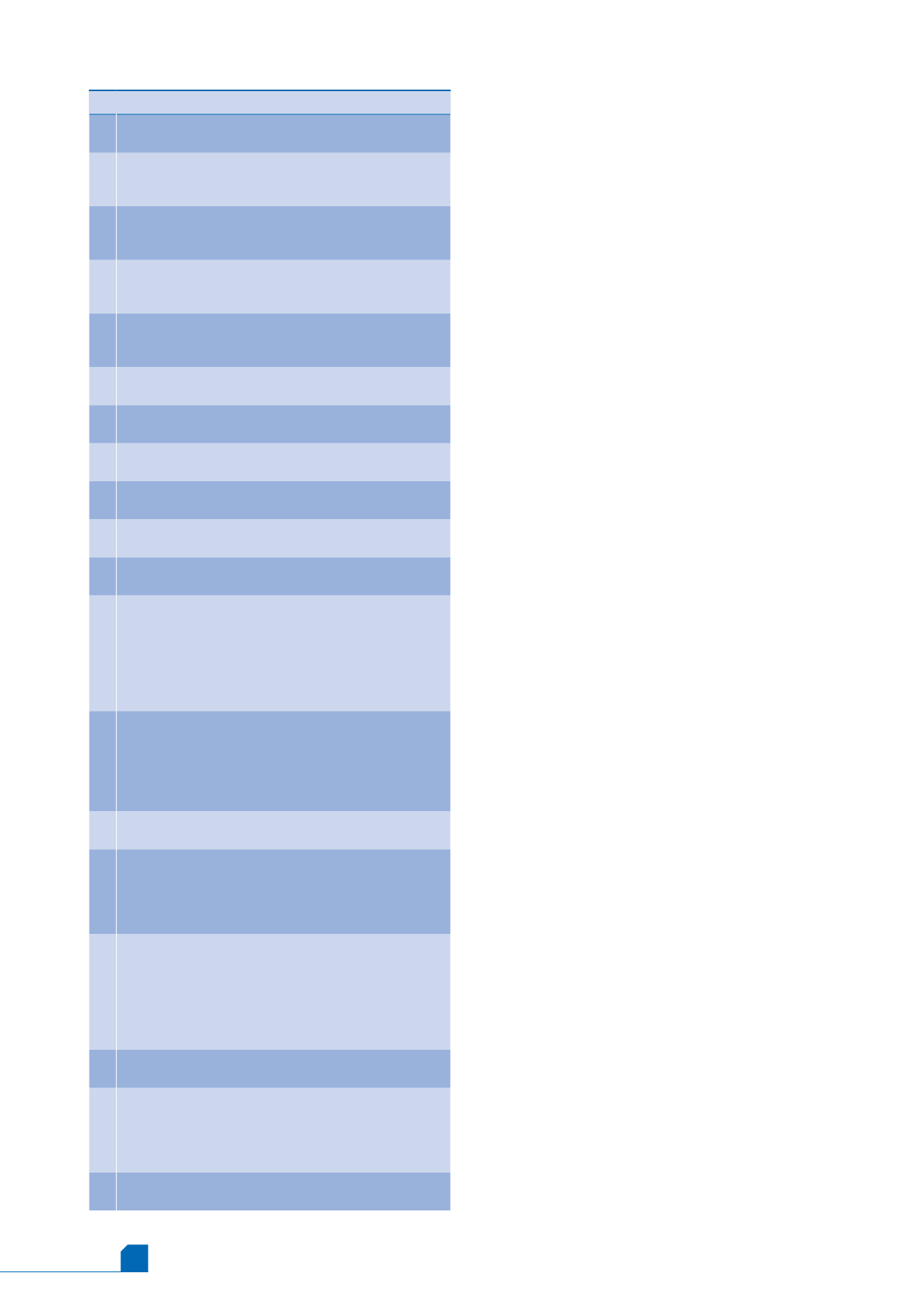

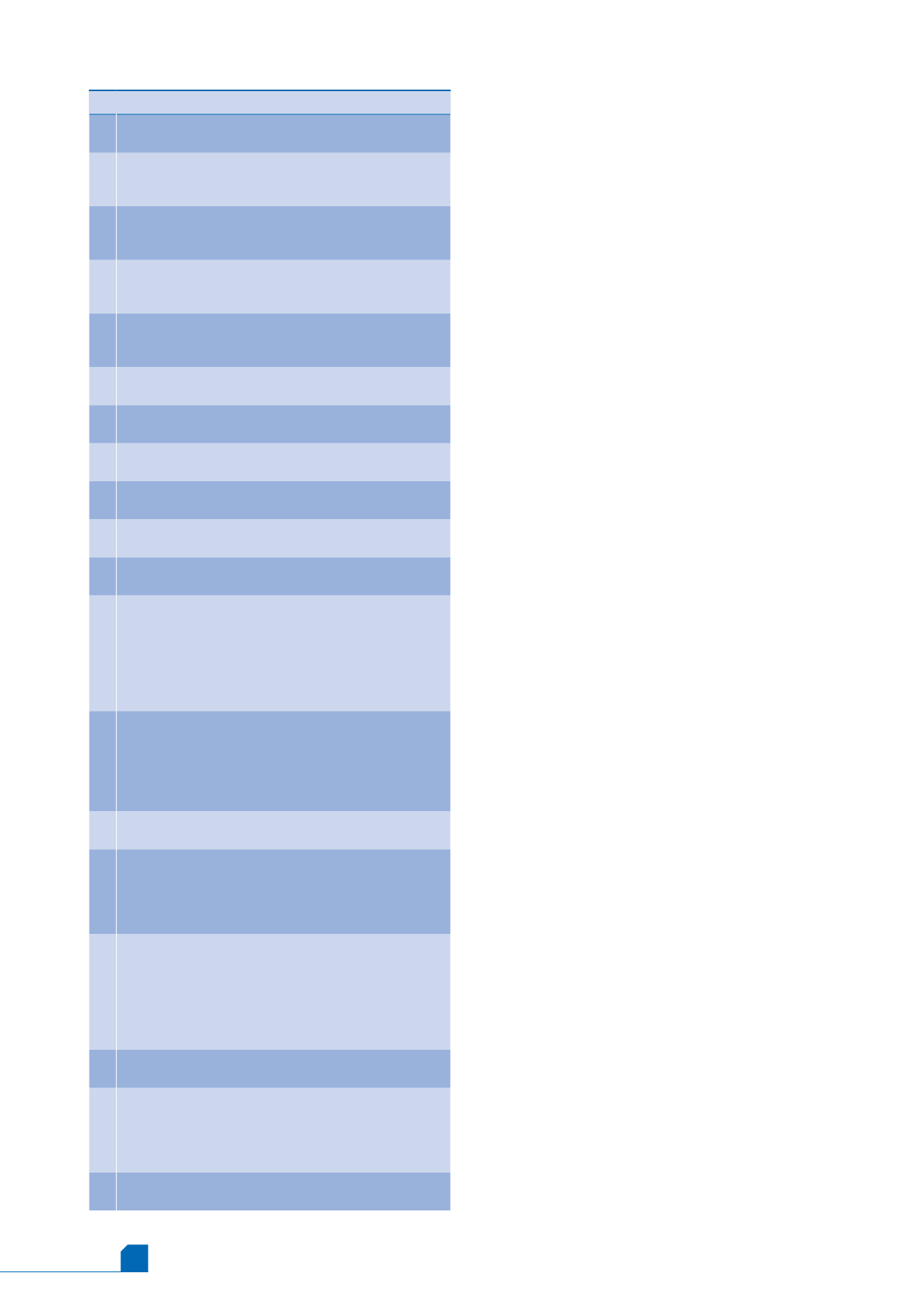

Table 1.

Relief network checklist

1

Check that the PSV/control valve/BDV/XV layout in the

model is as per the final plot plan/3D piping model.

2

Check that the routing of all individual PSV outlet laterals,

flare headers and sub-headers is as per the actual (final)

piping isometrics.

3

Check that inner diameter (ID), length and required fittings

for all PSV outlet laterals/flare sub-headers/flare headers

are based on the final piping isometrics.

4

Check that the correct pipe schedule (based on the actual

selected pipe class) has been selected for all PSV laterals,

sub-headers and headers.

5

Check that the flare knockout drum(s) have been modelled

correctly with respect to type (vertical/horizontal), location

and dimensions.

6

Check that the flare stack height and diameter are based on

final vendor data.

7

In case a liquid seal drum is being used, check that an

adequate pressure drop has been included for the same.

8

Check that the flare tip diameter has been input based on

final vendor data.

9

Check that the flare tip pressure drop curves have been

input based on final vendor data.

10

Check that all the relevant relieving scenarios in the plant or

complex have been built in the model.

11

For each relieving scenario check that all the active PSVs

have been correctly selected.

12

For each relief valve check that the following data have

been input based on the final relief valve datasheet:

(a) Set pressure.

(b) Normal (kg/hr).

(c) Molecular weight (usually calculated based on the

component-wise composition data entered).

(d) Relieving temperature and pressure.

13

Check that the following data for each relief valve have

been based on the final relief valve vendor datasheet:

(a) Relief valve type.

(b) Orifice designation.

(c) Outlet flange diameter.

(d) Relief valve rated flow.

14

Check that the system back pressure has been entered

based on the overall project design data.

15

Check that the following data have been entered as per the

overall project design data:

(a) Atmospheric pressure.

(b) Ambient temperature.

(c) Wind velocity.

16

Check that the following constraints have been entered as

per overall project design data:

(a) Mach number constraints (these may be different for

headers and sub-headers).

(b) Liquid and vapour velocities (if applicable).

(c) Noise data.

(d) Constraints on rho*v2 (if applicable).

17

Check that an appropriate thermodynamic model, e.g., Peng

Robinson method, has been selected for VLE and enthalpy.

18

For two phase systems check that an appropriate method,

e.g., Beggs and Brill (Homogeneous) method, has been

selected for pressure drop calculations. For single phase

systems, the more rigorous adiabatic pressure drop method

should be used.

19

Check that there are no Mach number/choked flow

violations in any of the pipe segments.

Find out

Serving the tan

TSA16UpdatedAdv