June

2016

HYDROCARBON

ENGINEERING

34

When post combustion gases can be accurately measured,

flare CE is typically determined by the following equation,

where CE (%) is the combustion efficiency, expressed as a

percentage.

n

n

Equation one:

Where: CO

2

= the volume concentration of CO

2

in the

plume once combustion has ceased; CO = the volume

concentration of carbon monoxide (CO) in the plume once

combustion has ceased; HCi = the volume concentration of the

i

th hydrocarbon (HC) compound remaining in the plume once

combustion has ceased; n

i

= the number of carbon atoms in the

Figure 1.

FlareSentry™ unit.

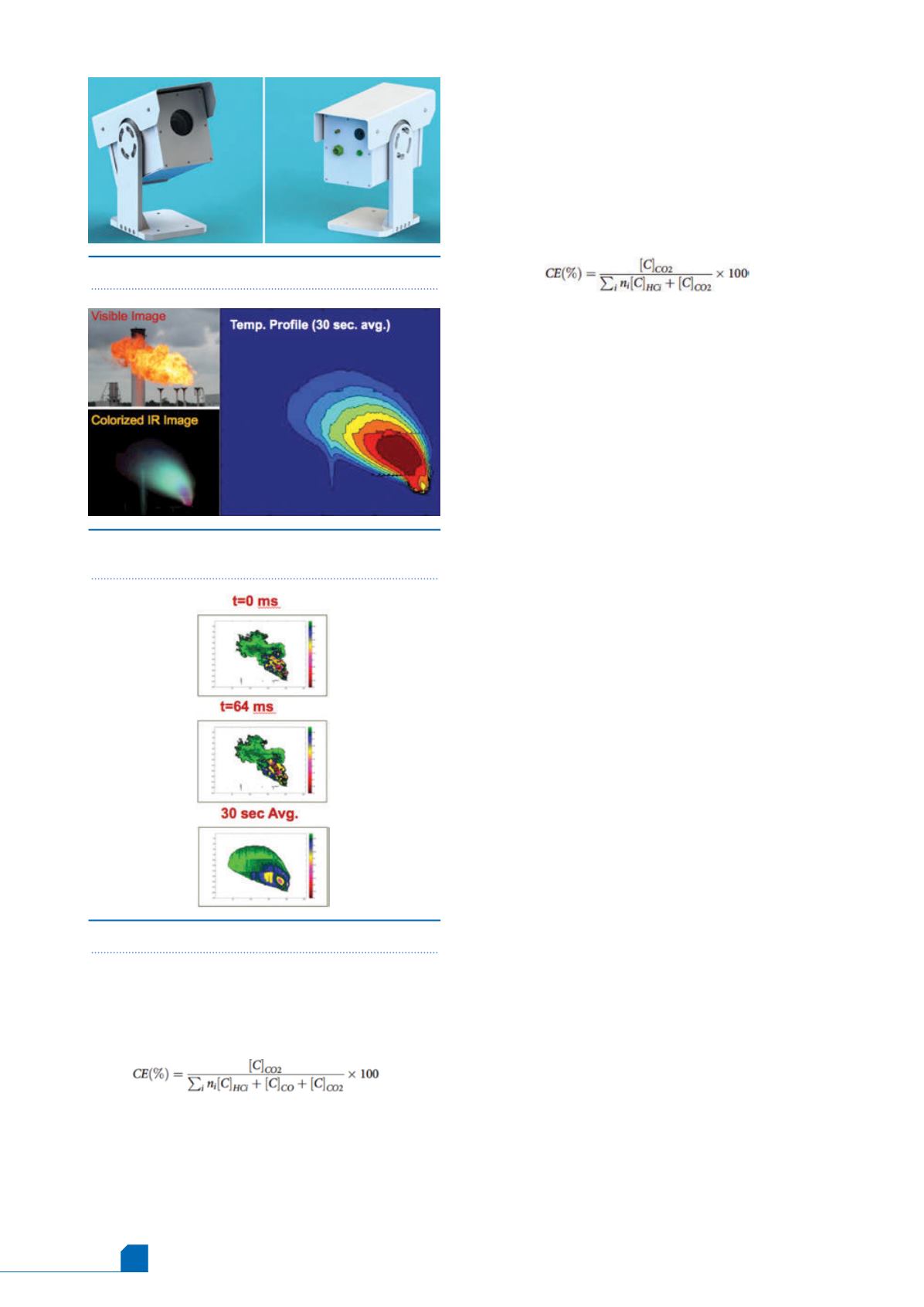

Figure 2.

Comparison of visible, infrared and

averaged profile images.

Figure 3.

Comparison of pixel images over time.

i

th HC compound; and i = the

i

th hydrocarbon compound in the

flare vent gas. When there is only one compound,

i

= 1.

When there is no unburned HC (HC

i

= 0) and no product of

incomplete combustion, such as CO in the plume (CO = 0), the

combustion is complete and CE is 100%. Under most common

conditions, the concentration of CO as a product of incomplete

combustion is measured in orders of magnitude lower than either

CO

2

or HC. For this reason, CO can be neglected in the CE

calculation. Therefore, equation one becomes equation two.

n

n

Equation two:

EPA rulings dictate the required DRE for flare systems, but, as

shown in equations one and two, flare performance (as

determined by destruction of HC) can be measured by CE. As

equation two directly compares unburned HC and its ultimate

combustion product (CO

2

), the CE calculated by equation two

can also be used as an approximation of DRE for HC – that is, how

much HC is destroyed regardless of howmuch is in the CO stage.

The known shortcomings of current indirect monitoring

methods, in combination with the new EPA standards and

deadlines, drove the development of a new flare CE

measurement and monitoring method – a technology that can be

used to directly, autonomously and continuously monitor flare

performance in real time.

The new method for flare CE measurement and monitoring

was first proposed by Zeng, et al., in 2012 and has been proven

through a series of large scale validation tests. It is based on a

unique multi-spectral infrared (IR) imager that provides a high

frame rate, high spectral selectivity and high spatial resolution

(Figure 1).

The method can be deployed for short term flare studies or

for permanent installation providing real time continuous flare CE

monitoring. In addition to the measurement of CE, the method

also measures and reports the level of smoke in the flare flame,

regardless of whether it is day time or night time. The

measurements of both CE and smoke levels provide the flare

operator with a real time tool to identify and operate at the

‘incipient smoking point’ to optimise flare performance.

The multi-spectral IR imager simultaneously measures the

relative concentrations of combustion products, CO

2

and

unburned HC at the pixel level. The relative concentrations of

CO

2

and HC levels measured at each pixel are used to calculate

the CE for that pixel, which represents a path-averaged CE for a

column of combustion gases represented by the pixel. A CE

value for the overall flare, at any given moment, is calculated by

averaging the CE values of the pixels that represent the outer

layer of the combustion zone of the flare where combustion has

ceased.

A CE value representing the flare at any given moment is

calculated by averaging CE values of the pixels that represent

the outer layer of the combustion zone of the flare. The imager

has a high frame rate (11 - 30 frames/sec.) that results in a data

acquisition cycle of 91 - 33 ms. The short data acquisition cycle

means that the path length through the plume depth can be

considered constant for each measurement (frame). This

addresses the significant limitation of other imaging-based

technologies with long data acquisition cycles (e.g., 1 sec.

[Figure 3]). As the data acquisition cycle increases, the

uncertainty due to the changing conditions (plume depth)

increases and the accuracy of the result will suffer. This new

method has been developed into the FlareSentry

TM

,

multi-spectral infrared (IR) imager – the first practical,

autonomous, real time monitoring device for flare CE.