June

2016

HYDROCARBON

ENGINEERING

28

various flare header configurations possible to suit different

project requirements. Some of these are described below:

n

n

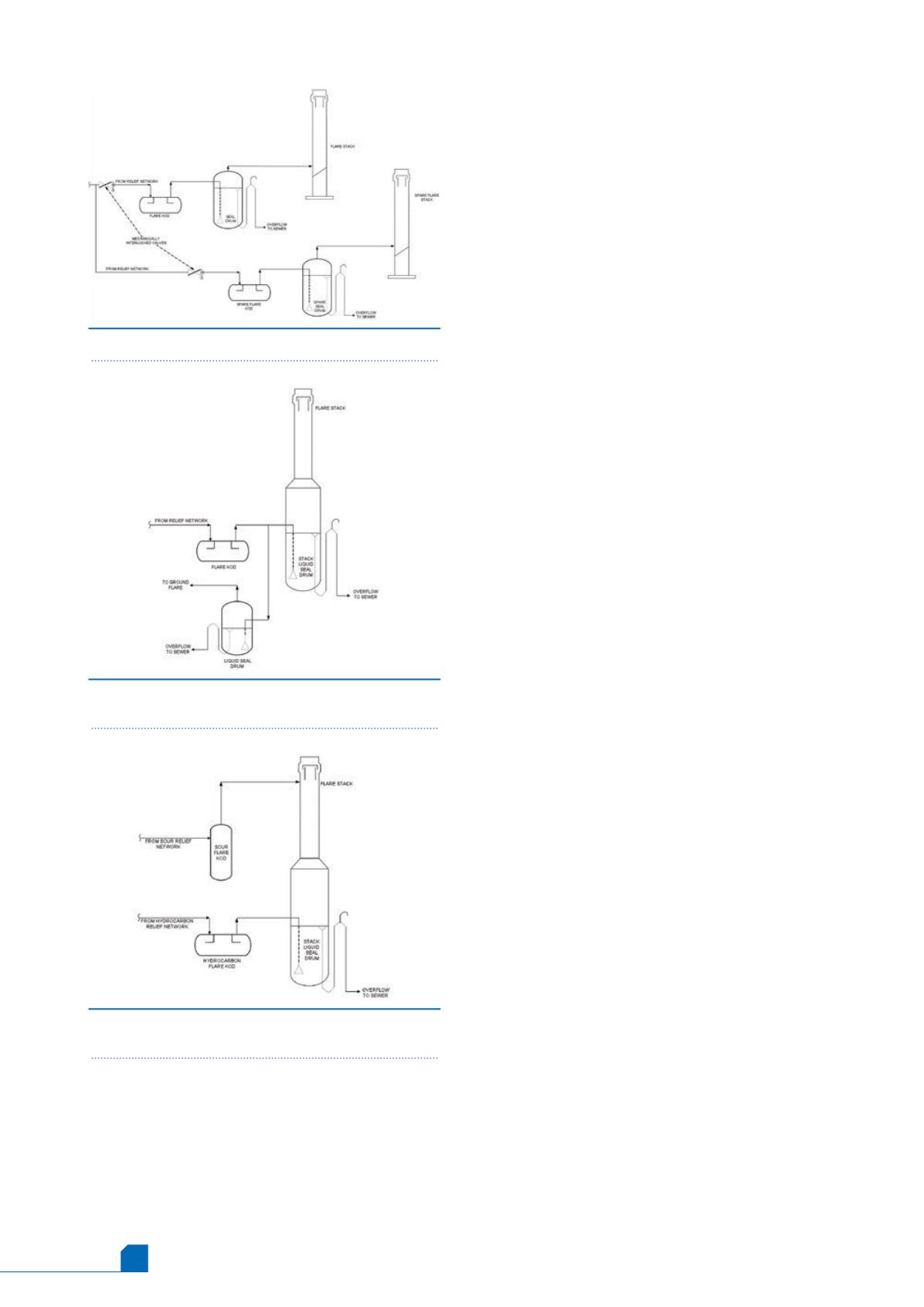

100% standby flare: a 100% spare flare knockout drum,

liquid seal drum and stack are provided, which would

ensure 100% availability of the flare at all times (Figure 1).

Mechanically interlocked isolation valves, along with well

documented safe operating procedures, are used to line up

Figure 3.

Low capacity sour flare tied in to

hydrocarbon flare stack.

Figure 1.

Mechanically interlocked, 100% spare flare.

Figure 2.

Ground flare operating in conjunction with

elevated flare.

the spare flare. The two stacks with demountable tips, one in

operation and one on standby, are mounted on a common

derrick structure so that the spare tip can be lowered for

inspection without shutting down the operating flare. The

flare regulations followed in some countries, e.g., Russia,

1

require the provision of a 100% spare flare knockout, liquid

seal drum and stack.

n

n

Separate low pressure (LP) and high pressure (HP) flare: in a

very large refinery or petrochemical complex where several

hundred pressure safety valves (PSVs) have widely different

set pressures, and high loads from the PSVs have high set

pressures, the overall system economics may favour the

provision of separate HP and LP flare headers. This is so that

higher back pressures can be permitted at the outlet of those

higher pressure PSVs, thereby reducing the diameter of the HP

flare header. The provision of separate smaller HP and LP

knockout drums, rather than a single large common knockout

drum, can also be explored. However, the flare design

regulations followed in some countries

1

require that

dedicated HP and LP flare systems should be provided and all

relief valves set at 30 bar (g), or higher, need to be connected

to the HP flare.

n

n

Two separate headers connected to a single knockout

drum: sometimes, from a layout perspective, it may be

possible to route two separate flare headers to a single

knockout drum by separate inlet nozzles, so that even if

there is simultaneous flow in both the headers during peak

flaring, only the common outlet header from the knockout

drum to the stack, which is not expected to be long, is sized

for the total flow.

n

n

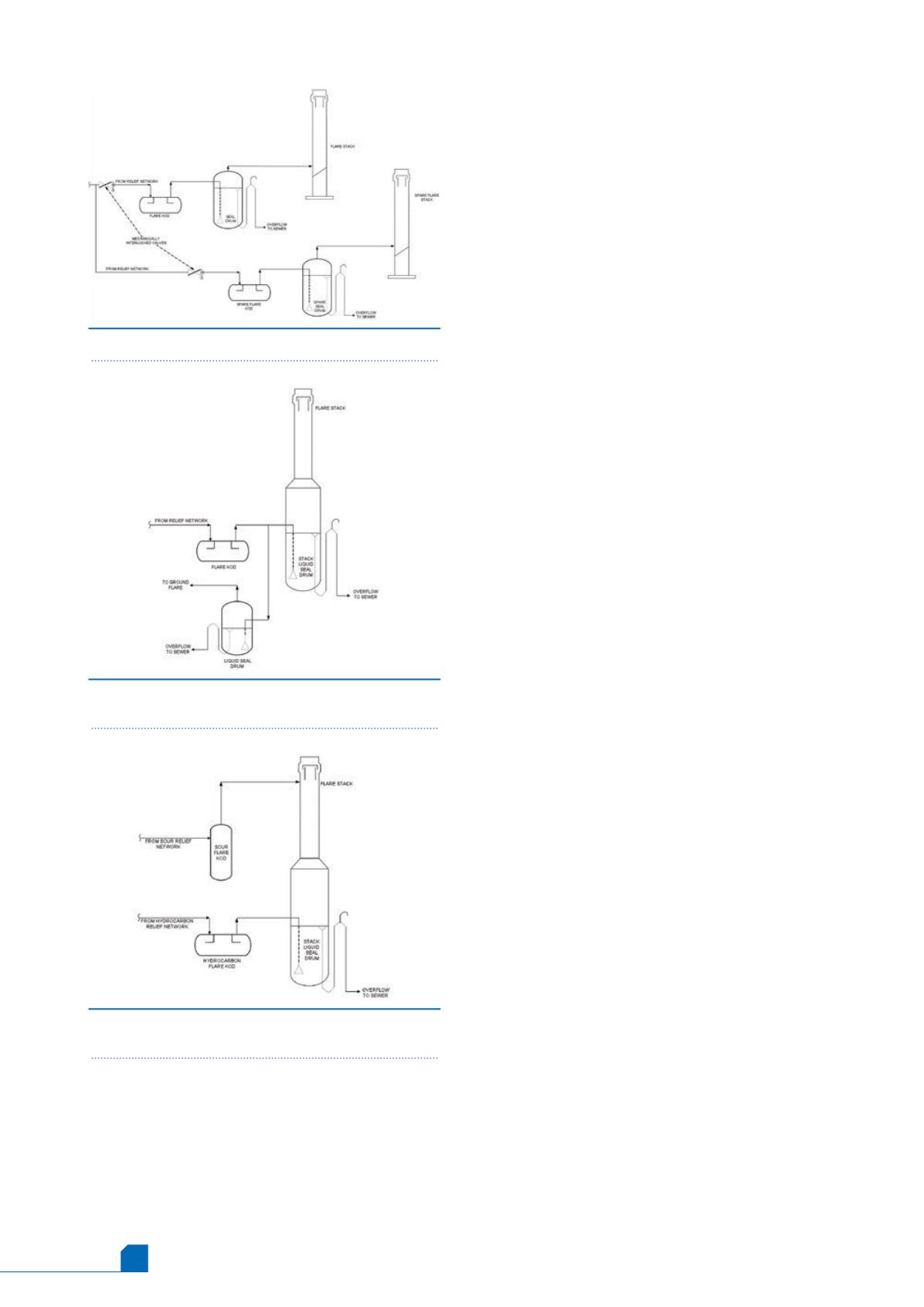

Combination of elevated and ground flare: an enclosed

ground flare needs to be considered in case the plant is

located in an environmentally sensitive area (e.g., a densely

populated area or one in which there is a possibility of

disturbing the local fauna). However, the ground flare

becomes uneconomic if the peak flaring load is very high. In

such cases, the combination of an enclosed ground flare

operating with an elevated flare stack can be explored

(Figure 2). The peak flare load can be diverted to the

elevated stack by means of a properly designed liquid seal

drum.

n

n

Sour flare header of low capacity tied in to a hydrocarbon

flare: in a refinery where the peak sour flare relief load was a

small fraction of the peak hydrocarbon relief load, the heat

traced sour flare header was tied into the common elevated

stack at the base of the molecular seal (Figure 3). The

metallurgy of the stack, tip and molecular seal were selected

considering the composition of the sour gas.

Sizing of the relief network

The sizing of a relief network is critical for the safety of the entire

facility. An improperly sized relief network could lead to excessive

vibrations and the possible rupture of a flare header/sub-header,

which could cause major accidents in an operating plant. The

availability of commercial software usually equipped with inbuilt

thermodynamic models, for the sizing of relief networks, has

greatly reduced the effort required for sizing a relief network,

although the user needs to pay careful attention to the inputs

being used by the program (a relief model checklist is presented in

Table 1).

Some of the major items that need to be carefully reviewed

when sizing a relief network are:

n

n

Back pressure at unit battery limit: in a large complex with a

large number of relief valves from several process units,