June

2016

HYDROCARBON

ENGINEERING

32

tied into a radially projecting nozzle at an angle less than the

vertical, in order to lower the flare header and pipe rack

elevation, therefore reducing cost.

Generally, two flare knockout drum pumps are provided,

one in operation and one on standby; however, it should be

ensured that at least one of the pumps is on emergency power

or, alternatively, on a steam turbine drive.

Flare stack

The height of the flare stack should be fixed based on the

specific project flare radiation and pollutant ground level

concentration criteria. Rigorous thermal radiation and

dispersion calculations need to be carried out to arrive at an

acceptable stack height, keeping in mind the requirements of

the design standard being used and the requirements of the

local regulatory bodies.

The provision of a system for continuous monitoring of

the operational flare stack is of vital importance. Several

options listed below are available for the purpose:

n

n

The provision of dedicated closed circuit television

(CCTV), which visually monitors the operational flare tip

from the main control room, is the simplest and most

commonly used system.

n

n

Opacity meters may be installed to continuously monitor

the flame, which can also be programmed to automatically

inject a calculated quantity of steam, thus ensuring that the

flare is smokeless within a certain range of capacity (the

generally acceptable smokeless load is around 10 - 15% of

the peak flare load from economic considerations).

n

n

Burn-back thermocouples provided on the flare tip, with

alarms on distributed control systems (DCS), would ensure

that the flame is not ‘burning back’ and causing potential

damage to the flare tip. For increased reliability, dual

thermocouples with a separate thermowell for each pilot

may be considered. Alternatively, retractable

thermocouples may be provided as these can be taken

out for maintenance without shutting down the flare.

n

n

Provision of a flame failure alarm on the DCS, which alerts

the operator in case of ‘flame out’.

n

n

The provision of an infrared (IR) video camera is another

reliable flare monitoring tool as it permits visual monitoring

of the flare tip and is not affected by adverse weather

conditions. It can also be programmed to automatically

control the quantity of assist gas, which needs to be injected

into the flare tip when flaring gas with a low heating value.

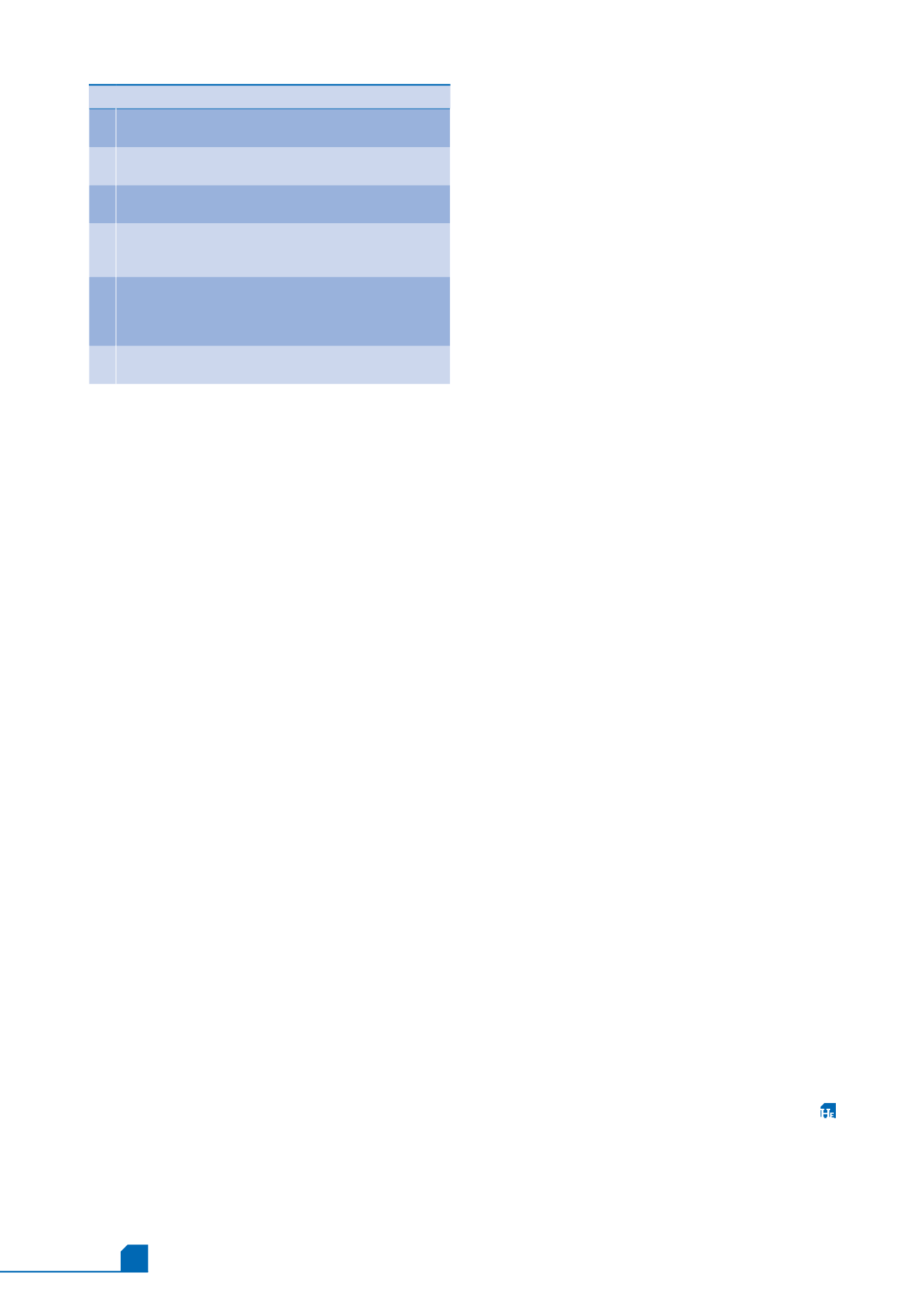

Table 1 (continued).

Relief network checklist

20

Check that there are no velocity violations based on data

entered.

21

Check that there are no back pressure violations for any of

the relief valves in a given scenario.

22

Check that there are no slug flow violations for any pipe

segments.

23

Check that the back pressures at the unit battery limit/PSV

outlet flange are within the limit specified in the project

relief system design basis.

24

Check that there are no temperature violations for any

segment of piping (based on the maximum acceptable

temperature for carbon steel/stainless steel piping – as the

case may be).

25

Check that there are no noise violations for any of the

piping segments.

Flare header purge

Flare header purges should be provided at the stagnant end of

each header/sub-header to ensure that a small positive flow

through the network exists at all times. Low pressure refinery fuel

gas is the generally accepted purging medium. However, it should

be ensured that a back up purging medium is available, in the case

of failure or unavailability of the primary purge. Furthermore, an

emergency nitrogen purge should also be provided, which sweeps

the main header following a hot release and subsequent cooling

of the hot flared gases, to prevent shrinkage and the development

of a vacuumwith possible air ingress into the system.

Smokeless flaring

The opacity of the flared gases is measured using the Ringlemann

number (#1 Ringlemann is 20% opacity while Ringlemann 0 is

clear).

2

The flared gas composition and heating value are the two

inherent factors that are responsible for the production of smoke

during flaring. Unsaturated hydrocarbons, which contain double

and/or triple bonds, are responsible for the smoky flame.

Smokeless flaring over a range of capacity (usually around 10 - 15%

of design capacity from economic considerations) is

accomplished by the injection of a calculated quantity of steam

or air into the tip. Steam assist is more effective as steam can

supply more momentum, enhancing ambient air-fuel mixing, as

well as ambient air entrainment. Air may be used in cases where

steam is unavailable.

Provision of assist gas

In cases where the heating value of the flared gases is particularly

low (less than 200 Btu/ft

3

for unassisted flares and 300 Btu/ft

3

for assisted flares),

2

incomplete combustion of the flared gas

could occur and, so, a calculated quantity of assist gas (usually

refinery fuel gas or LP natural gas) is injected into the flared gas in

order to boost its heating value, thus ensuring complete

combustion. The flared gas is analysed and its heating value

estimated by the use of a Btu analyser, which is then used to

compute the quantity of assist gas required to boost the heating

value of the flared gas to the target value of 200 or 300 Btu/ft

3

.

Conclusion

Flare designs could range from simple utility flares to enclosed

ground flares, which may be required to operate alone or in

combination with an elevated flare, and frommultiple injector

steam assisted flares to air assisted flares. The exact flare header

configuration to be employed needs to be examined considering

the specific requirements of the project, the overall economics of

the system, as well as the layout of the units in the complex with

regard to the flare design regulations being followed. A rigorous

analysis of all possible relief scenarios is required to check that

the relief network has been adequately sized. Furthermore,

particular care should be taken to ensure that the stack radiation

criteria and pollutant ground level concentration are within the

limits specified in the project design criteria/flare design

regulation being followed. One should ensure that a reliable stack

monitoring system is in place and adequate purges have been

provided at all dead ends of the flare header and sub-headers.

References

1.

Russian PB-03-591-03, 'Rules for the Design and Safe Operation of Flare

Systems', 1992.

2.

API Standard 521, 'Pressure Relieving and Depressuring Systems',

6

th

Edition, 2014.