June

2016

HYDROCARBON

ENGINEERING

24

hydrocarbon processing industry, paying close attention to

design for operational safety, measurement accuracy and

reliability to meet regulatory requirements, and to sustain low

total cost of ownership.

Meeting pollution requirements

The EPA has issued the final amendments to the new source

performance standards (NSPS) for process heaters and flares

at petroleum refineries.

n

n

40CFR60 Subpart Ja: total sulfur measurements.

§

§

Determine sulfur dioxide (SO

2

) emissions from the

flare.

§

§

Measurement ranges of 1.1 - 1.3 times the maximum

anticipated sulfur concentration.

n

n

40CFR60 Subpart Ja: hydrogen sulfide (H

2

S)

measurements.

§

§

Determine the hydrogen sulfide (H

2

S) in the fuel gas

to the flare.

§

§

Short term limit of 162 ppmv as a feed to the flares.

§

§

Span value for this measurement is 300 ppmv H

2

S.

n

n

40CFR60.18: net heating value.

§

§

Maintain a minimum Btu content and measure net

heating value to the flare.

§

§

300 Btu/ft

3

or greater if the flare is steam-assisted or

air-assisted.

§

§

200 Btu/ft

3

or greater if the flare is non-assisted.

The PGC5000 series of analysers provides a versatile

platform to combine these three measurements in the

optimal oven and controller configurations to minimise

capital cost, and focus on maximum measurement

availability, ease of maintenance and regulation compliance.

Total sulfur measurements

A recent development from ABB provides the ability to

measure, independently, the hydrogen sulfide (H

2

S) and the

total sulfur within a single PGC5007 total sulfur analyser,

reducing the initial investment cost of the flare analytical

system and the total cost of ownership.

For total sulfur measurements (outlined in 40CFR60

Subpart Ja), ABB’s PGC5007B analyser employs a field proven

combination of hardware and application experience to

provide a simple and robust measurement result: sample

injection

→

oxidation

→

separation

→

measurement.

Application features and benefits include:

n

n

Simple design: one injection valve, one set of columns,

one detector, no complex backflush or heart-cut

techniques.

n

n

Guaranteed, interference-free measurement without

matrix or stream composition dependencies.

n

n

Sulfur specific detection.

n

n

Wide analytical measurement range from 0 - 100%, to

satisfy measurement ranges of 1.1 - 1.3 times the

maximum anticipated sulfur concentration.

Hydrogen sulfide measurements

The PGC5007B is based and built according to ASTM method

D7041-04(2010), Standard Test Method for Determination of

Total Sulfur in Light Hydrocarbons, Motor Fuels and Oils by

Online Gas Chromatography with Flame Photometric

Detection. With hundreds in service around the world, this

Figure 4.

Sulfur detection and limits are mandated by

worldwide local agencies.

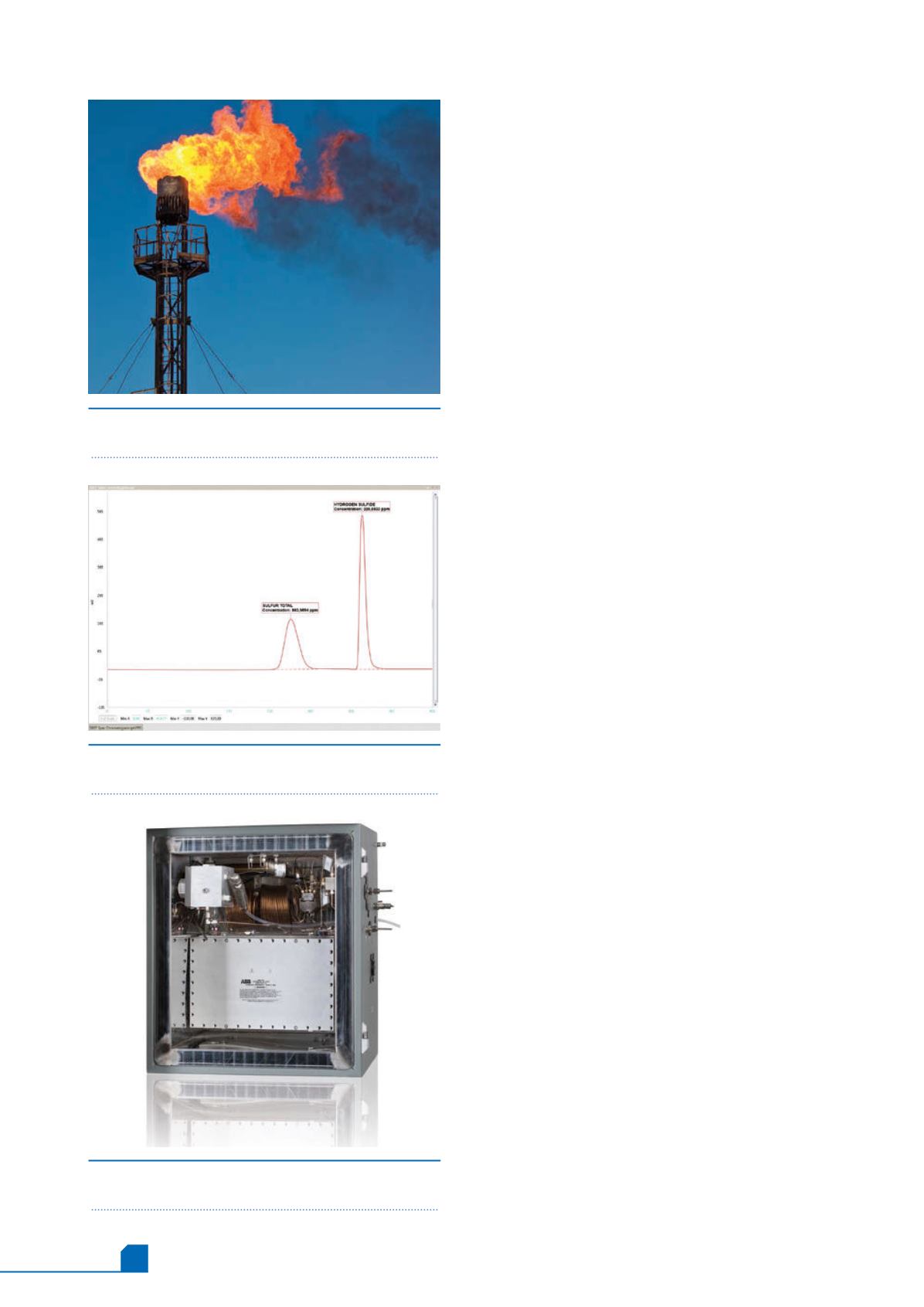

Figure 6.

The PGC5007 interior oven with proven

valves, vapouriser, furnace, column and detector.

Figure 5.

Hydrogen sulfide (H

2

S) and total sulfur can

be independently measured within a single analyser.