June

2016

HYDROCARBON

ENGINEERING

25

analyser method continues

to provide the hydrocarbon

processing industry with an

online analytical method

with precision and bias data

2 - 5 times better than other

analytical techniques for

total sulfur measurements.

As a recent development,

ABB adjusted the injection

valve type from a liquid to a

vapour, and developed a

specific and dedicated H

2

S

measurement analytical

module that provides a

system capable of measuring

both H

2

S and total sulfur in

the same analytical oven

and detector.

For hydrogen sulfide measurements (outlined in

40CFR60 Subpart Ja), there are two options:

n

n

PGC5000B class oven or PGC5007 with additional H

2

S

measurement option.

§

§

A direct measurement of H

2

S in fuel gas with a

measurement range of 0 - 300 ppm.

§

§

This analytical method uses a sample injection with

backflush and selector to eliminate interference with

a flame photometric detector for H

2

S.

§

§

Sulfinert-treated hardware for chemical inertness and

measurement accuracy.

§

§

Fuel gas stream isolation from flare gas sulfur

excursions.

§

§

Zero potential of cross contamination when flare gas

sulfur exceeds 300 ppm.

§

§

Separate and independent daily validation and CGA

audit analyses.

§

§

Total sulfur and direct H

2

S measurement from the

same oven.

n

n

Standard PGC5007B total sulfur analyser.

§

§

The EPA has approved the use of a total sulfur

analyser for the H

2

S measurement provided it can

meet a 0 - 300 ppm measurement range. Since the H

2

S

content in fuel gas will always be less than the total

sulfur reported from the flare gas, this analyser can

also be used to confirm the H

2

S measurement.

§

§

Measurement can be made using the total sulfur analyser

system designed for the flare gas stream. Due to the

broad range of measurement, the total sulfur analyser

above can be used to assess compliance with the short

term 162 ppmv H

2

S concentration in the fuel gas.

§

§

Both sulfur measurements can be made within a single

analyser. One PGC5007B can satisfy the 0 - 300 ppm

H

2

S and the 1.1 - 1.3 times the maximum anticipated

total sulfur requirements.

§

§

Lower overall cost of ownership.

Net heating value

For the net heating value, a recommended analyser model is

PGC5000B (Btu measurement). There are direct measurements

of the hydrocarbons in the fuel gas and a net heating value is

calculated from the results.

n

n

Sample injection, hydrocarbon separation and

measurement using a multiport TCD.

n

n

The measurements are used to calculate the net

heating value of the fuel gas stream.

n

n

Chromatography designed to eliminate any potential

water interferences on the Btu value.

n

n

Multiple ASTM methods and GPA calculation

packages available.

n

n

Common analytical technology and hardware to the

PGC5007B total sulfur analyser.

n

n

Complete analytical solution for the entire flare

monitoring package.

n

n

Parallel method of analysis to the total sulfur (TS)

application.

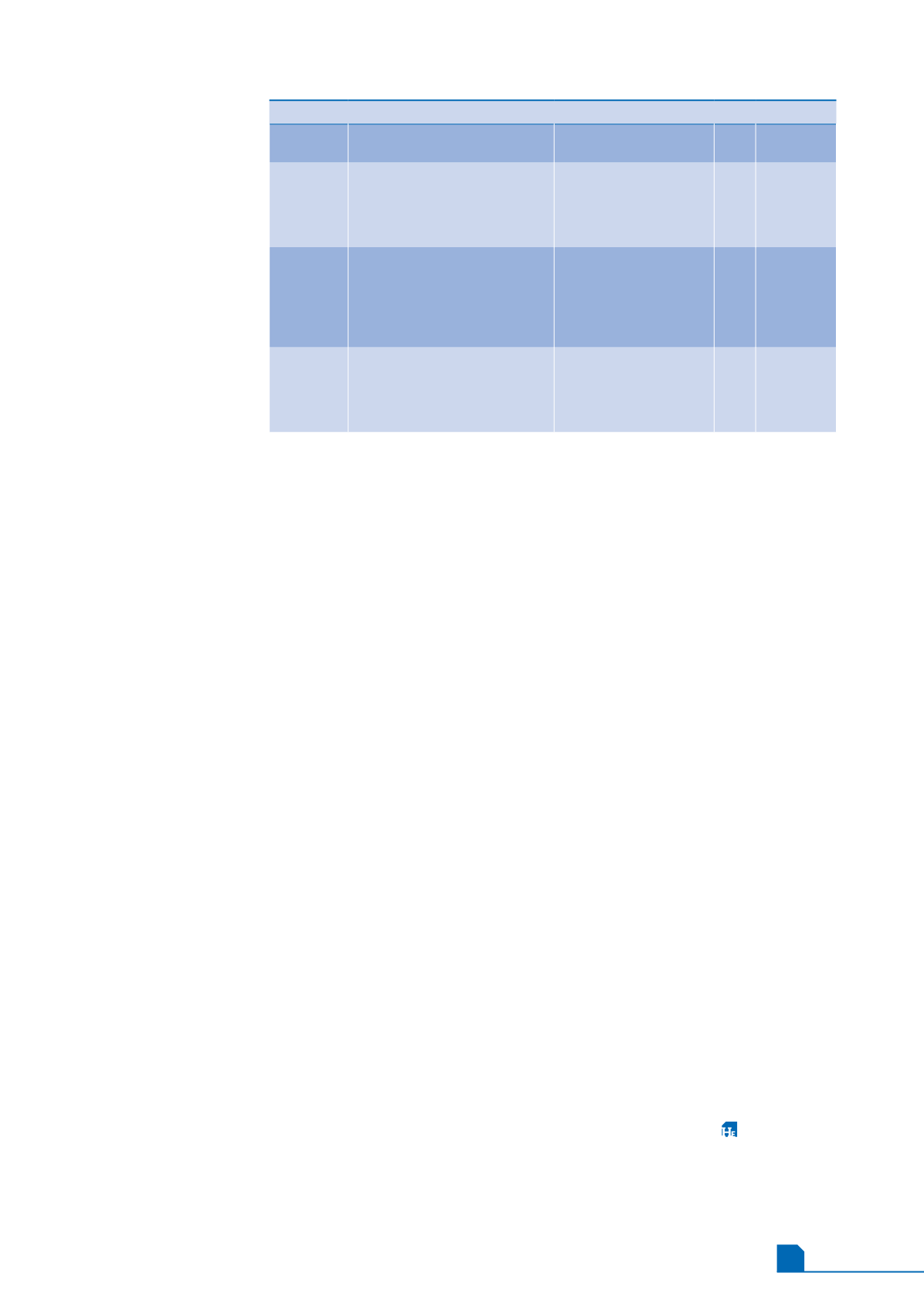

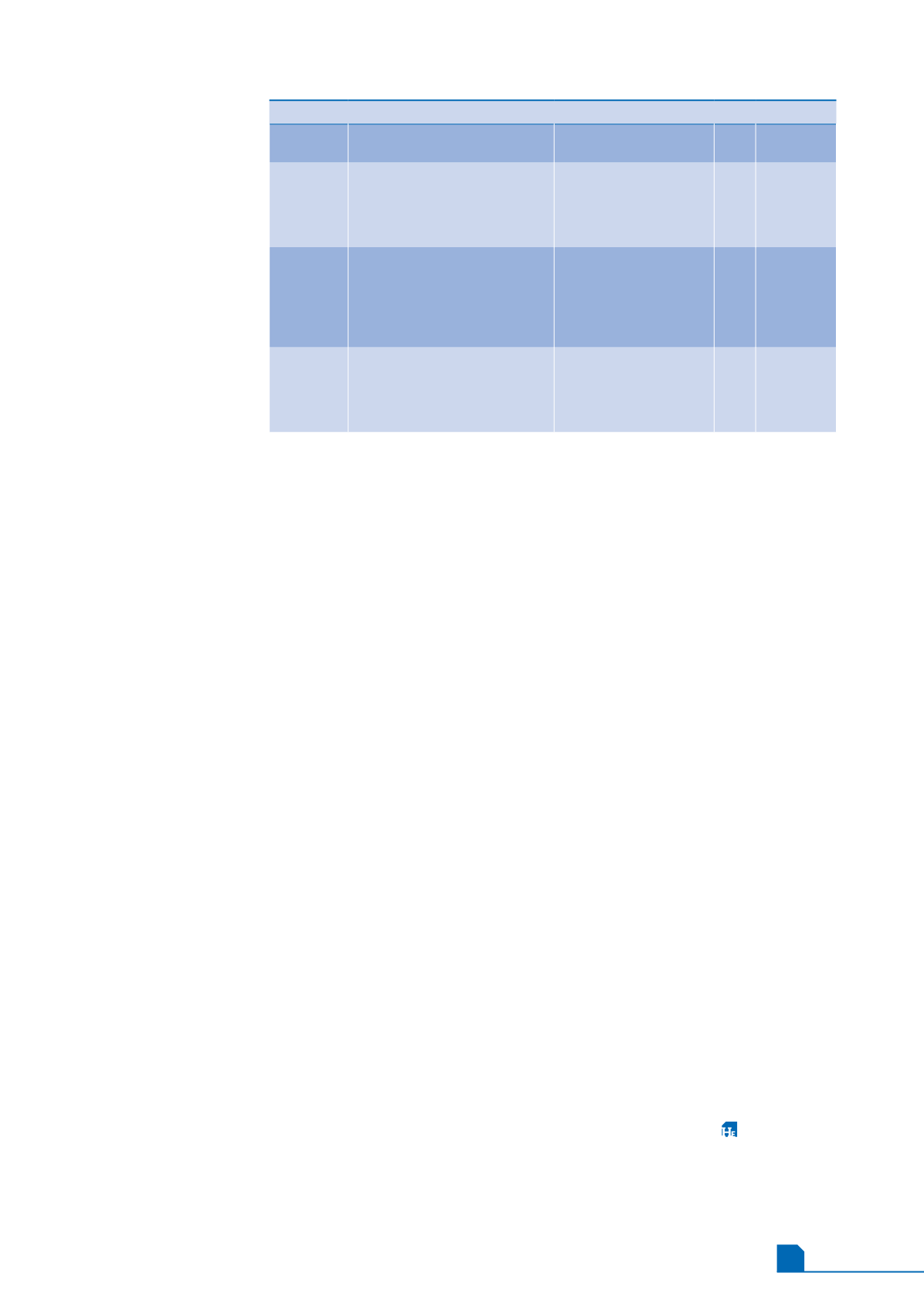

Taking into account the data presented in Table 1,

application option one, based on two B class ovens

represents the most compact solution for meeting the

three measurements. Application option two outputs

the H

2

S as part of the total sulfur measurement. In both

cases, the second B class oven is dedicated to the Btu

calculation. Application option three distributes the

analysis among three independent ovens, for the

maximum measurement control and isolation. Dedicated

sample valves enable automatic switch to low, mid

and high measuring ranges. The PGC5000 series

provides a flexible platform, which allows different

application options for meeting the H

2

S, total sulfur and

Btu analysis.

Conclusion

Process gas chromatographs provide an efficient and accurate

solution for online and automatic sampling, and analysis of

flare effluents. Ensuring operational safety, measurement

accuracy and reliability, and low cost of ownership, this

analytical method has proven to be particularly useful in an

environment of increasingly stringent standards for process

heaters and flares at petroleum refineries.

Acknowledgement

The ABB Lewisburg Process Analytics Team also provided

contributions to this article.

Table 1.

Flare gas analysis – application summary

Application

option

Total sulfur application method H

2

S application method Btu

oven

Number of

ovens

1

Two internally switched ranges

Total sulfur = TS (0 - 5000 ppm)

Total sulfur = TS (5000 - 100%)

Other ranges possible to satisfy the

1.1 - 1.3 x requirement

Directly measured

component:

H

2

S (0 - 300 ppm)

Yes Two B ovens

2

Three internally switched ranges

H

2

S measured as TS (0 - 300 ppm)

Total sulfur = TS (300 - 5000 ppm)

Total sulfur = TS (5000 ppm - 100%)

Other ranges possible to satisfy the

1.1 - 1.3 x requirement

Measured as total sulfur

Reported H

2

S (0 - 300 ppm)

Yes Two B ovens

3

Two internally switched ranges

Total sulfur = TS (0 - 5000 ppm)

Total sulfur = TS (5000 ppm - 100%)

Other ranges possible to satisfy the

1.1 - 1.3 x requirement

Directly measured

component:

H

2

S (0 - 300 ppm)

Yes Three B

ovens