June

2016

HYDROCARBON

ENGINEERING

36

operation, optimising flare operation from both a cost and

CE/DRE perspective. Automatic adjustments to fuel or assist

gas, steam and air can be made via the closed loop control

system, based on real time conditions of the flare system,

lowering costs for supplemental fuel and providing more

accurate maintenance of required DRE.

Benefits of the FlareSentry include:

n

n

Elimination of inaccuracies associated with the current

practice of monitoring indirect parameters (heating value,

velocity, etc.) versus direct monitoring of CE.

n

n

Autonomous operation eliminates ‘aiming’ or manual data

reduction.

n

n

Providing SI assists the operator with achieving incipient

smoke conditions day and night.

n

n

Continuous data availability provides real time CE and SI to

operators for optimal flare performance.

n

n

Non-contact monitoring minimises operating and

maintenance (O&M) cost, which is high for indirect

monitoring methods because the sensors for these

methods are in direct contact with the flare vent gases.

n

n

A short measurement cycle (milliseconds, averaged over

seconds to one minute) enables quick response and

minimises cost for supplemental fuel.

n

n

An industrial interface allows for closed loop flare

operations based on direct CE and SI values.

n

n

Providing CE values along with SI and pilot status gives the

operator a complete picture of flare performance with a

high level of confidence.

n

n

Simplified monitoring, reporting and compliance activities.

Conclusion

Regulations related to flare operations continue to tighten, but

employing the best available technology, such as FlareSentry, to

monitor and control the actual CE of a flare system in real time

gives operators the necessary tool to meet the challenge.

Bibliography

1.

COBURN, J., RTI International Memorandum on Flare Control

Option Impacts for Final Refinery Sector Rule, 2015,

EPA-HQ-OAR-2010-0682-0748.pdf.

2.

US Environmental Protection Agency, Parameters for properly

designed and operated flares, 2012, EPA Office of Air Quality

Planning and Standards (OAQPS):

. epa.gov/ttn/atw/

flare/2012flaretechreport.pdf (accessed 24 March 2015).

3.

US Environmental Protection Agency, Fact sheet, Proposed

petroleum refinery sector risk and technology review and new

source performance standards, 2014:

/

petrefine/20140515factsheet.pdf (accessed 24 March 2015).

4.

ZENG, Y., MORRIS, J., and DOMBROWSKI, M., Validation of a newmethod

for measuring and continuously monitoring the efficiency of industrial

flares, Journal of the Air &Waste Management Association, 2016, 66:1,

pp. 76 - 86, DOI: 10.1080/10962247.2015.1114045.

5.

ZENG, Y., MORRIS, J., and DOMBROWSKI, M., 'Multi-spectral infrared

imaging system for flare combustion efficiency monitoring,' US Patent

9,258,495, 2012. Issued on 9 February 2016.

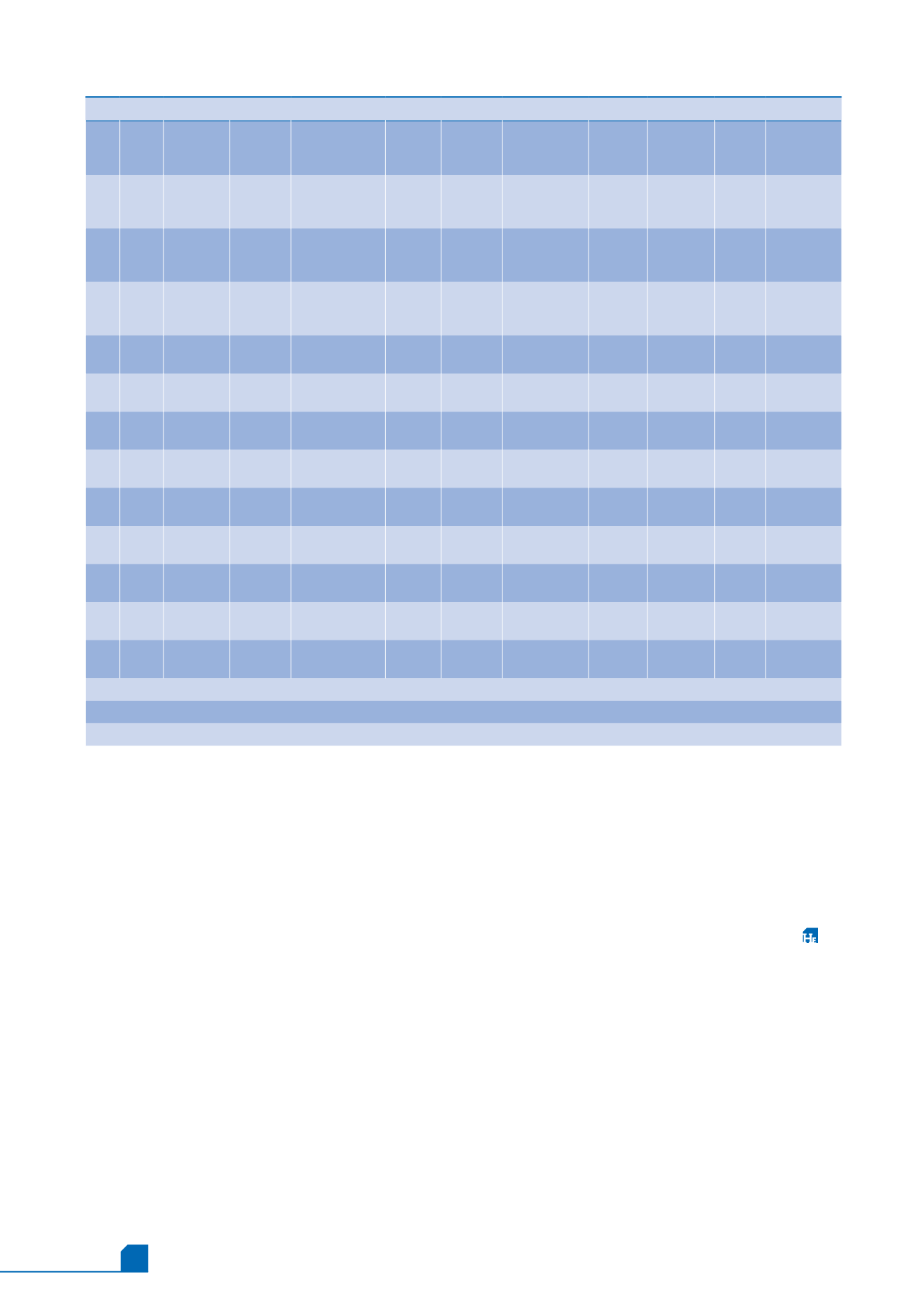

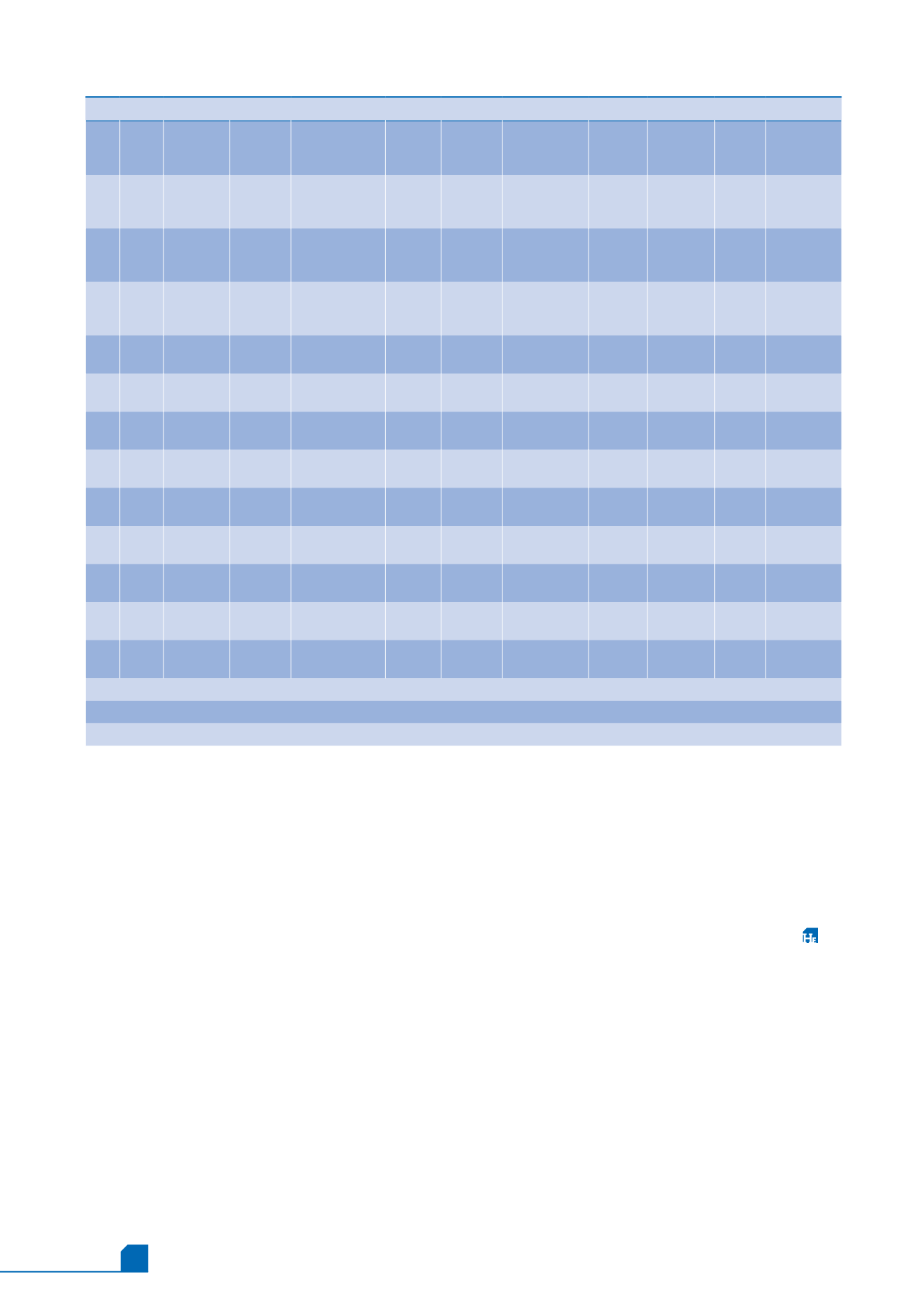

Table 1 continued.

Flare CE validation test results

Test

no.

Flare

type

Fuel

Fuel

flow rate

(lb/hr)

Stoichiometric

air

Steam/

HC

(lb/lb)

CZNHV

(Btu/ft

3

)

CE-extractive

method

CE-new

method

CE

difference

Smoke

index

Avg. O

2

in extracted

sample

26 MPGF Propane/

N

2

(50/50)

2448

99.99%

99.80% -0.19% 0.35

18.19%

27 MPGF Natural

gas

(100%)

3300

100.00% 99.80% -0.20% 0.26 17.03%

28 MPGF Natural

gas

(100%)

3300

100.00% 99.90% -0.10% 0.32 15.76%

29 QFS Propane

(100%)

4640

0.52

1035

99.99%

98.70% -1.29% 0.56 19.91%

30 QFS Propane

(100%)

4640

0.52

1035

99.97%

99.10% -0.87% 0.70 17.60%

31

QFS Propane

(100%)

1879

1.25

571

97.75%

97.50% -0.25% 0.46 19.90%

32 QFS Propane

(100%)

1879

1.25

571

67.48%

77.20% 9.72% 0.83

20.24%

34 QFS Propane

(100%)

1537

1.53

489

59.99%

73.60% 13.61% 0.17

19.94%

36 QFS Propane

(100%)

1537

1.53

489

70.57%

76.60% 6.03% 0.15

18.75%

37 QFS Propane

(100%)

1537

1.53

489

83.15%

85.10% 1.95% 0.21

18.38%

38 QFS Propane

(100%)

3328

0.71

850

99.67%

99.10% -0.57% 0.40 17.38%

39 QFS Propane

(100%)

3328

0.71

850

99.82%

99.40% -0.42% 0.46 18.86%

Average CE difference between the two methods – all 28 tests: 0.50%

Number of tests with oxygen <19.5% (indication for good extraction): 18

Average CE difference between the two methods – 18 tests with oxygen <19.5%: -0.10%