June

2016

HYDROCARBON

ENGINEERING

72

the efficiency of the unit. Online particle sensors provide

the ability to automatically program in the desired

concentration and clarity of any process stream. The

sensors offer real time, continuous viewing and analysis

of particulates under process conditions, and can be

programmed to automatically adjust the operation of

equipment to ensure on specification conformance. For

example, a refinery’s distributed computer system (DCS)

or programmable logic controller (PLC) program can

receive data from the online sensors, which is processed

by the analysis software to manipulate the back-flush

timing on the electrostatic separator. The process to

reduce the back-flush medium then becomes automatic,

allowing for immediate savings in the cost of back-flush

material while ensuring the desired process quality stays

within specification. Through the simple integration of

online sensors and analysis software with

a refinery’s electrostatic separator,

revenue loss from off specification

product and the length of time it takes for

tank settling is prevented.

Typical particle sensor data

collection

Table 2 illustrates a typical example of how

a refinery can determine the percent of

solids and particle size distribution within

any MCB from the FCC/RFCC in real time.

Measurements are captured using an online

digital camera with image and data analysis

software to isolate catalyst and ash

particles in the MCB.

Economics

The following offers an example of how

economic value is generated from

implementing automated online sensors,

analysis software and electrostatic

separation technology to remove FCC

catalyst fines from slurry oil, versus a

standard where settling tanks are used.

Refinery A operates an FCC unit with a

throughput of 80 000 bpd. The FCC unit

has a slurry oil product flow of 6.0 vol.% of

feed, or 4800 bpd at 0.0 API. The FCC unit

uses an electrostatic separator to remove

fines from 3000 wppm to <500 wppm. This

is equivalent to 2.25 tpd of fines. Assuming

2 tpd of sludge for every tpd of fines, a

total of 4.5 tpd of sludge and fines would

have accumulated in the storage tank. In

one year, approximately 1600 t would

accumulate in the storage tanks.

By using an electrostatic separator and

automated online sensors, upgrading the

slurry oil quality for high grade coke

production can provide Refinery A with

significant savings and increased revenue

potential on an annual basis.

Assuming a product value increase of

US$2/bbl of slurry oil, the added value is:

n

4800 bpd slurry oil product x 365 days x

US$2/bpd = US$3.5 million/y product value increase.

The only meaningful process cost for the electrostatic

separator is for recycle flow. For this scale, the recycle

flow rate would be 2 vol.% of the effluent, or 100 bpd. At a

cost of US$1/bpd, this cost is:

n

100 bpd recycle x 365 days x US$1/bpd = US$36 500/y

process cost.

Ignoring the labour and material costs of tank cleaning,

consider the landfill disposal cost of sludge, based on the

previously stated 1600 tpy of accumulation in the storage

tank. Assuming landfill disposal is US$1/lb (or US$2000/t),

the cost is:

n

1600 tpy x US$2000/t = US$3.2 million/y disposal cost

savings.

Table 2.

Sample collection

Main column sample

Sample description from sample container

MCBP decant oil

Image collection

Particles are sent through the flow

cell body and back-lit with a high

output LED strobe light. The particle

images are collected in real time

by the CCD camera. The image is

digitally transmitted to a PC with

software for analysis.

RFCC MCB at 5000 ppm.

Binary images

The image is broken down into

individual pixels. The intensity

difference between the particles and

the background allows the software

to determine which particles are in

focus, and their perimeter, as well as

the major axis, minor axis, area, and

other characteristics of the particle

dimensions.

RFCC CSO after separation;

approximately 50 ppm.

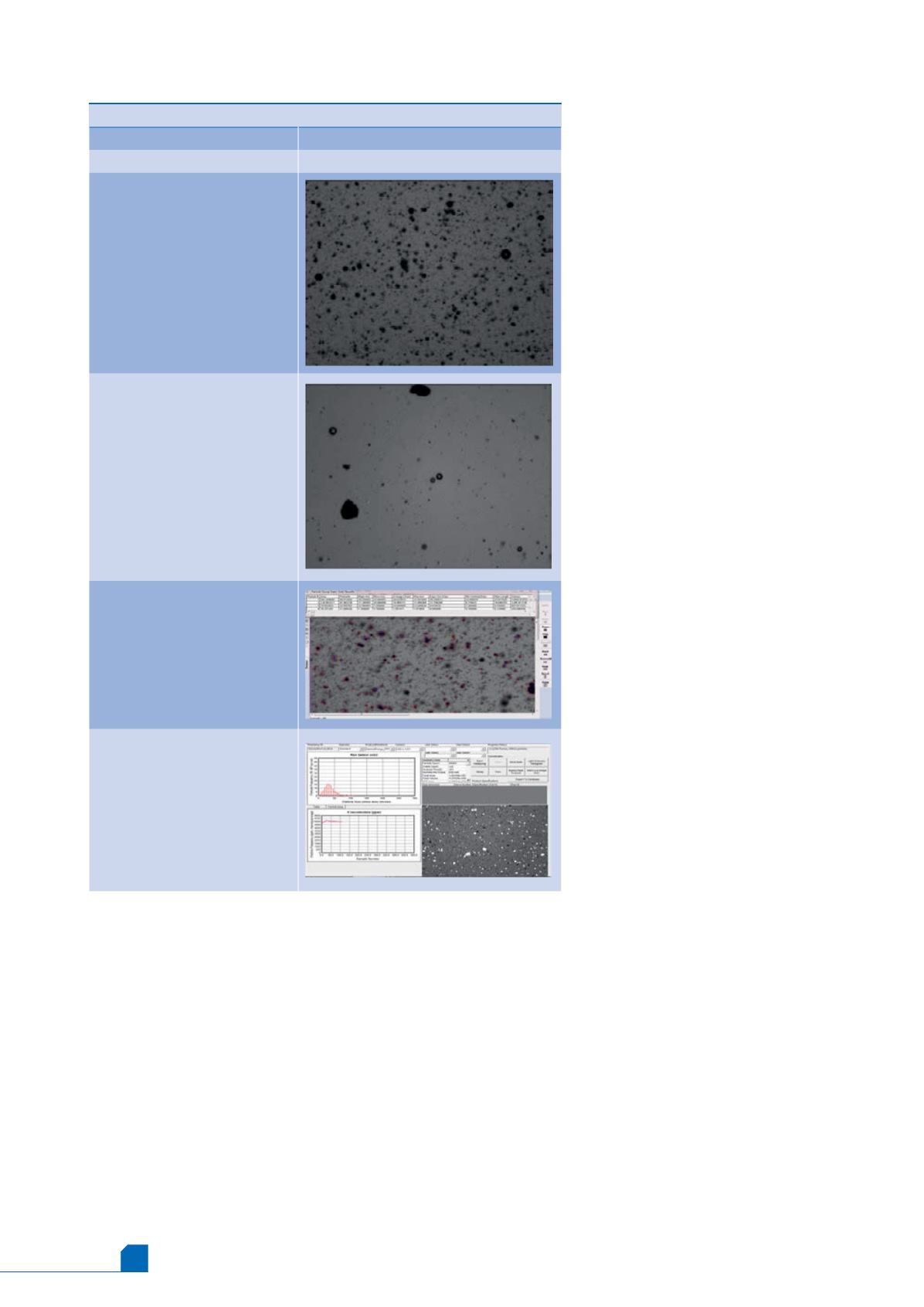

Analysis

Once the software determines the

particles size and shape, further

analysis is performed on individual

particles. The analysis includes

particle filters to enable users

to determine when particles are

dissimilar, or non-conforming, to the

entire distribution of particles.

Output

The software has analysed the

particles data, the information

can be stored and/or output to a

variety of locations. This includes

PC databases, a 4 - 20 mA current

loop, OPC and more.