Based on the example data above, Refinery A can

realise the following annual savings potential:

n

US$3.5 million/y additional product value increase –

US$40 000 process cost + US$3.2 million/y disposal

cost savings = US$6.7 million annual savings.

Catalyst savings might not be as valuable for a residual

unit, but would still be significant. Individual cases involving

deep residual cracking benefits should be calculated based

on a thorough knowledge of the RFCC unit feed, operating

conditions, catalyst characteristics, etc. It is important to

note that smaller catalyst particles returned to the unit have

an inherently larger surface to volume ratio, and could have

a considerably higher residual cracking activity than the

larger equilibrium catalyst held in the unit.

Other cases with slurry oil catalyst concentrations of

2000, 3000 and 4000 ppm and slurry uplift of US$2/bbl

have been shown to generate higher profit drivers for

a refiner. Savings from the use of the electrostatic

separator and particle sensors to maintain process clarity

for these concentrations range from approximately

US$4.5 - 11 million/y.

Conclusion

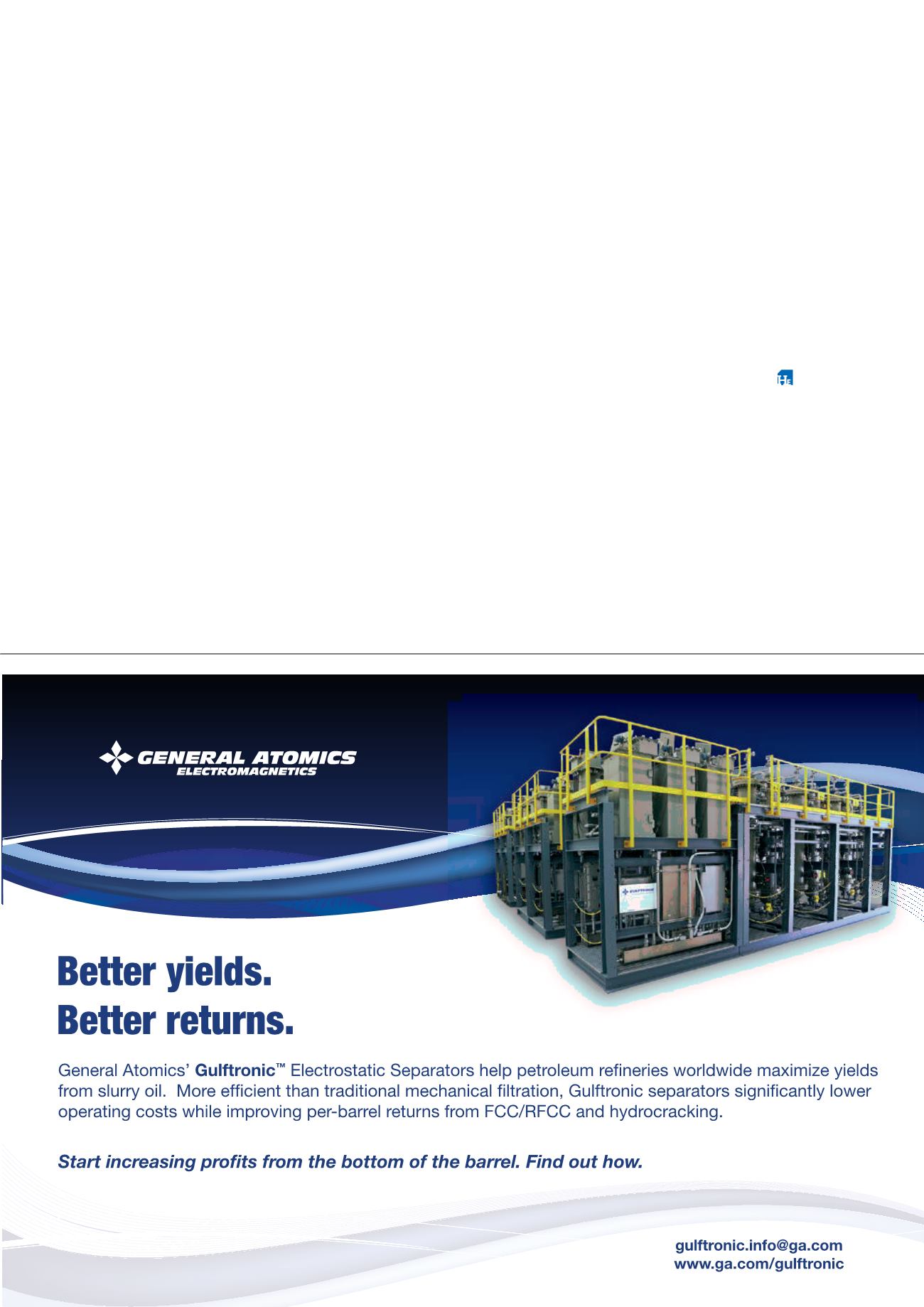

Online analysis of clarified slurry oil to maintain a high

grade of clarity to meet current market options can save

refineries without a catalyst removal option millions of

dollars a year. In many cases, meeting client demands for

clarified slurry oil in carbon black and fuel oils can realise

as much as US$1 million/month in revenue generation.

Deploying a reliable electrostatic separation technology

combined with real time, online monitoring techniques

provides operators with the confidence they are meeting

market specifications to improve profit potential.

The removal of FCC/RFCC slurry oil solids to low levels:

n

Permits clarified oil to be used in higher value

applications, yielding approximately US$2 - 4/bbl.

n

Reduces or eliminates the need for the disposal of

hazardous waste from slurry oil holding tank sludge.

n

Reduces fresh catalyst make-up costs through FCC

catalyst recycling.

n

Reduces additive costs by eliminating the need for

chemical settling aids.

n

Allows costly blending of higher grade products to be

used for other conversions at a higher profit.

References

1. GUERCIO, V. J., 'US Producing, exporting more slurry oil', Oil & Gas

Journal, 4 October 2010.

2. Platts, Methodology and Specifications Guide, 'Petroleum Product

& Gas Liquids: US Caribbean and Latin America', January 2012.

3. MINYARD, W. F., and WOODSON, T. S., 'Upgrade FCC Slurry Oil with

Chemical Settling Aids', World Refining, November/December

1999.

4. MOTAGHI, M., SHREE, K., and KRISHNAMURTHY, S., Anode Grade

Coke from Traditional Crudes, PTQ, Q2, 2010.

5. ELLIOTT, J. D., 'Impact of Feed Properties and Operating Parameters

on Delayed Coker Petcoke Quality', presented at the ERTC 2008

Coking and Gasification Conference.

6.

Archive/Optimize-value-from-FCC-bottoms.html.