June

2016

HYDROCARBON

ENGINEERING

76

Q&A

Q

Explain why catalysts are so crucial to refining and

petrochemical operations.

Catalysts are of paramount importance to the refining and

petrochemical industries, since they allow operators to carry out a

desired reaction faster and more selectively than in a non-catalysed

manner, which has huge benefits in terms of economics (e.g., higher

desired product yield, less formation of unwanted byproducts, lower

operating costs through lower operating temperature and/or

pressure), energy efficiency and safety. Almost all refining and

petrochemical products are upgraded by at least one catalytic

reaction during their production process.

q

To what extent has the downstream catalyst market

grown over the past 10 years, and what have been the

driving factors?

The downstream catalyst market has grown substantially in recent

years, driven by several factors: firstly, an increase in global demand

for refined products, mainly due to an increase in transportation fuels

demand (gasoline and diesel), and for petrochemicals. Secondly, the

specifications for transportation fuels have been tightened all around

the world, with more and more countries requiring ultra low sulfur

levels. Finally, the demand has increased mostly for light products and

middle distillates, whereas the global crude offer has become heavier,

which has resulted in an increased demand for conversion catalysts.

q

How have catalysts changed since your company began

operating in the industry?

Axens has successfully operated in the industry for more than

60 years through its mother companies IFPEN and Procatalyse, and

its catalysts have considerably evolved in order to reach the targets

of higher activity and stability, improved cost efficiency and lower

environmental impact. All aspects of catalyst design have been

optimised, from carrier composition, texture and shape to active

metals formulation. Since Axens invests a substantial portion of its

revenue in catalyst research and development (R&D), it can offer

some of the best catalysts available, and intends to continue this in

the future.

q

What are the main applications for your company’s

catalysts or catalyst technologies within the refining

and petrochemical industries?

Axens offers one of the widest catalysts and adsorbents portfolios to

the refinery and petrochemical industries, ranging from clean fuels

production over conversion solutions to aromatics production and

olefins purification. This may allow operators to benefit from Axens’

commercially highly attractive bundle offers.

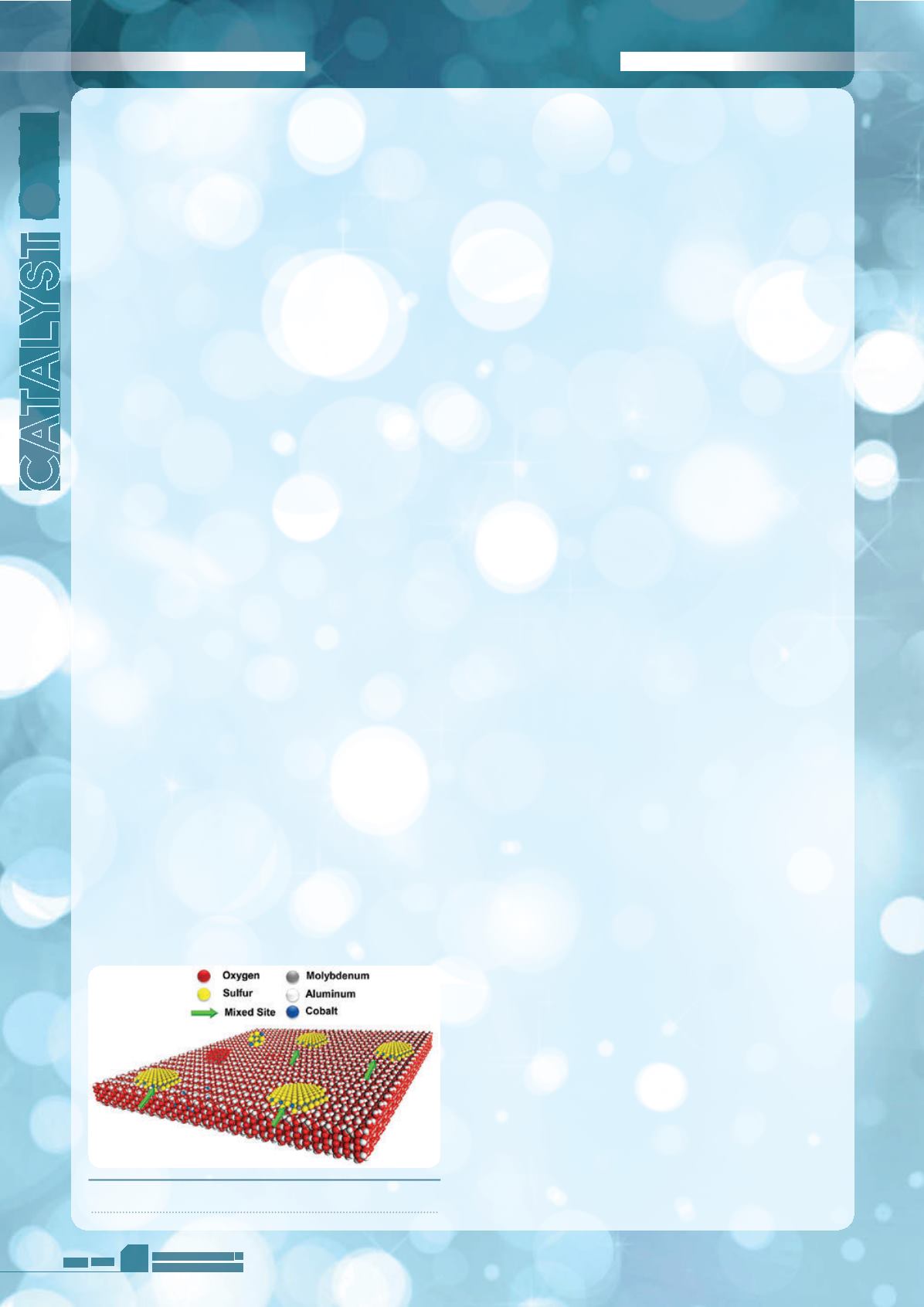

For hydrotreating, Axens has launched Impulse

TM

, a complete,

high performance family of hydrotreating catalysts combining high

stability with outstanding activity levels. Impulse catalysts achieve

high performance through maximising the amount of the catalytically

most active mixed Mo/Ni and Mo/Co sites by optimising promotion,

metal dispersion and support characteristics.

For hydrocracking, catalysts from the pretreating HRK series and

the hydrocracking HDK and HYK series are combined to achieve

operator’s conversion targets. The combination of the HRK, HDK and

HYK series enables operators to squeeze more middle distillates from

vacuum gas oil and heavy fractions, while reaching high conversion

levels and product quality.

Symphony

TM

is the latest generation family of reforming catalysts,

combining the best in catalyst support and multi-metal formulation

technologies. Compelling results are achieved for virtually all

reforming services: from fixed bed to continuous catalyst regeneration

(CCR), low to high density loading, lean to rich naphtha feed and high

to low octane severity. Contrasted with prior generation, best in class

reforming catalysts, Symphony catalysts show step out improvements

in yield, selectivity, coke stability and hydrothermal stability without

sacrificing activity, leading to a notable increase in unit profitability.

For olefins purification, the LD series catalysts are a market leader

for all liquid phase selective hydrogenation reactions, including the

purification of C

3

, C

4

, C

5

streams and pygas.

For sulfur recovery, Axens has pioneered the use of titanium

dioxide catalysts to boost Claus units efficiency and has

revolutionised the design of Claus tail gas treatment units by

introducing low temperature catalysts. Axens’ current portfolio ranges

from regular Claus alumina, boosted alumina for carbonyl sulfide

(COS) hydrolysis, pure titanium dioxide catalysts, benzene, toluene

and xylene (BTX) management catalysts and tail gas treatment

catalysts.

To purify many different gas and liquid streams, Axens offers a

wide range of molecular sieves, specialty aluminas and guard beds of

the AxSorb

TM

and AxTrap

TM

families.

The company also offers a wide and flexible catalyst management

service, Orchestra

TM

, delivering several benefits: reduced catalyst

change out costs while meeting guaranteed technical performances;

increased unit utilisation rate through optimised management of

turnarounds and operations; and maximised and sustainable used

product valorisation.

On top of this, the company as a licensor provides cutting edge

technologies, along with highly efficient equipment and profitability

boosting consulting services. This combination provides a unique

single source offering, enabling Axens to respond efficiently and

rapidly to all customer needs.

Q

What is the next 'big thing' in the downstream catalyst

market?

The refining sector faces a double challenge: provide an increasing

amount of ever-cleaner fuels, and find sources that do not rely on

crude oil and allow for a minimised environmental footprint (reduced

greenhouse gas emissions all along the lifecycle). Axens has developed

catalysts and technology to face these challenges, e.g., through the

hydroprocessing of vegetable oils or animal fats yielding ultra clean

middle distillates (Vegan

TM

), or through the conversion of synthesis

gas of various origins (natural gas, biomass) into waxy materials that

are hydrocracked into ultra clean liquid fuels (Gasel

TM

). In the field of

petrochemicals, bio-ethylene can be produced via dehydration of

renewable bio-ethanol (Atol

TM

).

ARNO FRITZ, AXENS

Impulse

TM

catalyst technology.