June

2016

HYDROCARBON

ENGINEERING

80

Q&A

Q

Explain why catalysts are so crucial to refining and

petrochemical operations.

Catalysts are not just crucial, they are fundamental to refining

and petrochemical operations, going back over 75 years. Eurecat

has been in operation for over 30 years, working to maximise

catalyst value through ex-situ sulfiding/activation (Totsucat®

process) and regeneration for reuse.

q

To what extent has the downstream catalyst market

grown over the past 10 years, and what have been

the driving factors?

The catalyst market over the past 10 years has been mainly

driven by the switch to ultra low sulfur diesel and gasoline,

and increases in pre-treatment severity for fluid catalytic units

and hydrocrackers due to new regulations (such as Tier 2 and

Tier 3, Euro V, and China V). Eurecat has seen the overall

catalyst market increase by two to three times over the past

10 years. The factors driving this growth have been increased

fuel demand, subsequent increased refinery throughput and

refinery expansion, as well as regulations requiring ultra low

sulfur distillates, gasoline and other transportation fuels.

q

How have catalysts changed since your company

began operating in the industry?

Catalyst activity has increased dramatically from 10 years ago.

Eurecat customers report that regenerated/regenerated and

rejuvenated catalysts today have higher activity than the fresh

catalysts from 10 years ago. Today’s catalysts each require

their own specific ex-situ multi-step sulfiding and activation

processes to achieve activity that is equal to in-situ sulfided

activity.

q

How are new catalysts or catalyst technologies tested,

and how long does the development process tend to be?

Eurecat works closely with the fresh catalyst manufacturers to

develop its proprietary recipes for Totsucat (ex-situ

activation), Cracked Feed Protection (CFP), Passivation (for air

loading) and Hydrocracking Catalyst Activation with Acidity

Protection (HC-AP). The result is that catalyst manufacturers

can support their performance projections with Eurecat’s

ex-situ activation equal to in-situ activation.

Q

What are the main applications for your company’s

catalysts or catalyst technologies within the refining

and petrochemical industries?

Eurecat’s technologies focus primarily on the catalyst ex-situ

activation and spent catalyst regeneration for reuse or resale.

Eurecat works closely with the fresh catalyst suppliers to

develop new catalyst activation methods such as HC-AP, which

can reduce the hydrocracker startup time by 50% or more, as

well as Totsucat

(totally sulfided catalyst)

and Passivation, that

allow for loading activated catalyst under air.

q

What has been the company’s biggest technological

breakthrough in terms of downstream catalysts?

There have been four key breakthroughs for Eurecat: CFP,

HC-AP, Passivation and Palladium Catalyst Reactivation. CFP is

an option for the Totsucat, which allows cracked feed to be

introduced immediately at startup, instead of waiting the

typical three days. HC-AP provides Totsucat with acidity

protection for hydrocracking catalysts, which eliminates the

need for ammonia and provides the fastest and safest

cracking reactor startup. Startup times can be reduced by

50% or more. Passivation is an additional treatment to

Eurecat’s Totsucat ex-situ sulfiding and activation, which

allows the activated catalyst to be handled and loaded

under air. Standard Totsucat requires inert loading. Moreover,

in the coming months, Eurecat will launch a new process that

will allow the Totsucat catalyst to be transported in

supersacks instead of bins, as well as loaded under air. Lastly,

Eurecat's Recover Activity and Increase Selectivity (RAISE®)

process has been developed for palladium-based

hydrogenation catalysts.

q

Where do you see the downstream catalyst industry

in 10 years’ time?

As Yogi Berra once said, “It is tough to make predictions,

especially about the future.” With that said, Eurecat expects to

see higher and higher activity catalysts that are tailored to

specific feeds and conditions, instead of one or two high activity

catalysts for all distillate or gas oil applications. Eurecat sees

continued growth in its Totsucat ex-situ activation, as more

refineries maximise throughput and eliminate in-situ sulfiding

related problems. Regeneration for reuse continues to grow as

the regenerated/rejuvenated activity of new catalyst generations

exceeds the fresh catalyst activity of prior generations.

Eurecat foresees an increased emphasis on the catalyst

management and handling for environmental and safety reasons.

New catalyst unloading technologies, such as CARBODUMP®,

enable much more efficient catalyst removal from reactors,

without water flooding or personnel entry into reactors during

unloading. Pool management among different refineries

promotes the reuse of regenerated catalysts across a geographic

area, or across regions of the world.

q

How has the fall in oil prices affected the downstream

catalyst industry over the past 12 months?

The overall decrease in commodity prices that accompanied the

oil price decline reduced the cost difference between fresh and

regenerated catalyst to historic lows. However, a refiner

regenerating its own catalyst for reuse can still achieve cost

savings of 65 - 75% compared to fresh catalyst.

TIM CAMPBELL, EURECAT US, INC.

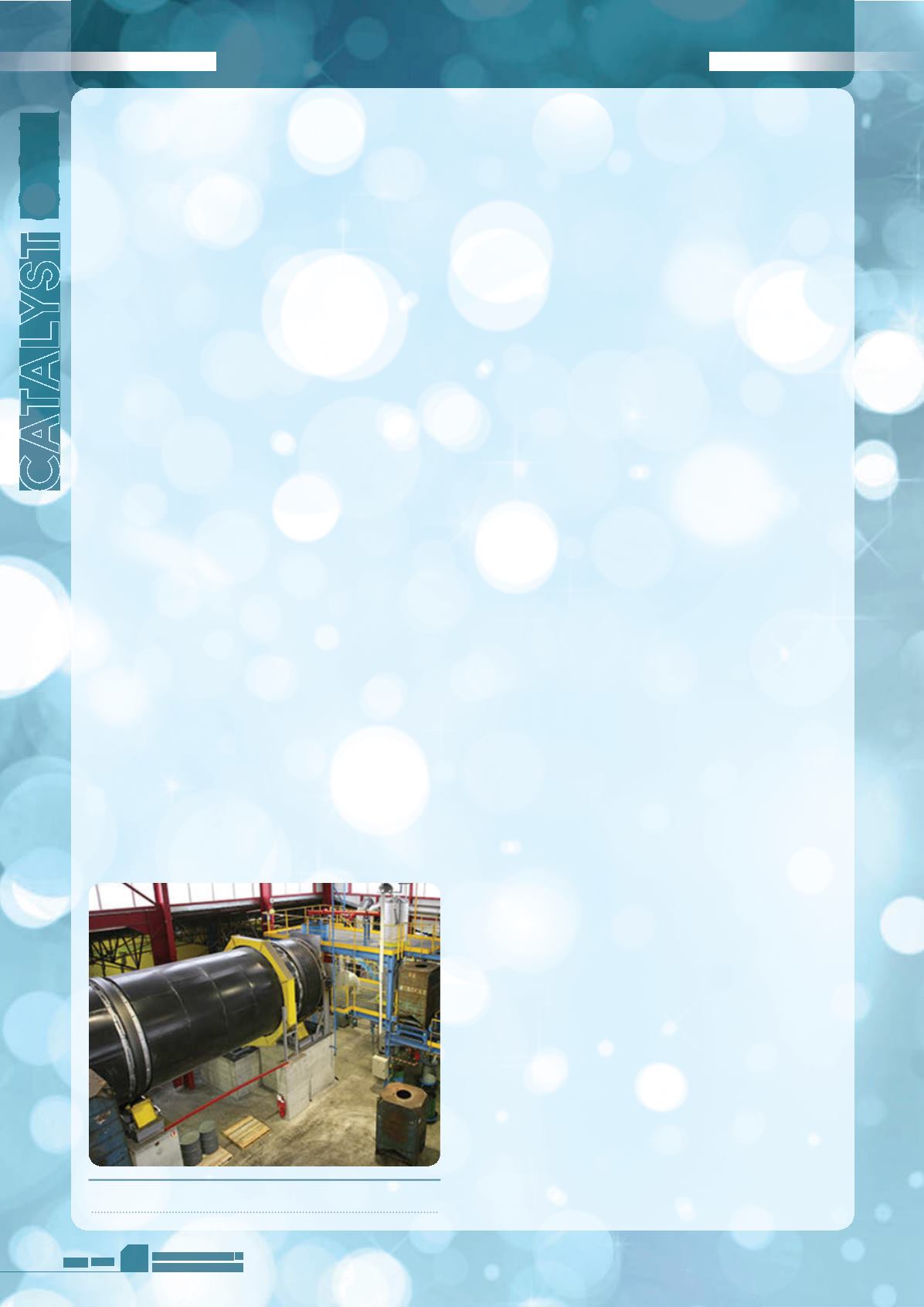

Eurecat regeneration unit.