weld defects), repair methods that involve minimal or no lost

production time can be viable. These methods are collectively

referred to as live repair.

Pipeline repair state-of-practice

Repair systems for subsea pipelines need to work within a

10 - 20 year perspective. Challenges of offshore pipeline repairs

increase significantly with increasing water depth. Divers have

historically performed most shallow water repairs – in deeper

waters, pipeline repairs have to be conducted via remotely

controlled technologies. Most subsea and onshore pipeline

repair technologies involve fittings that can be connected to

the pipeline via mechanical means or welding, such as couplings,

clamps, T-branch connections and in conjunction with use of

isolation plugs. In some geographic regions, specific technical

challenges and technology gaps can apply, and stakeholders

can benefit from the establishment of an emergency pipeline

repair system (EPRS) as a repair preparedness strategy. Additional

logistical challenges also apply if the offshore repair operations

involve isolating topside on a production platform. To date,

there are very few options for deep and ultra-deepwater

pipelines repair.

Compared to its offshore counterpart, onshore pipeline

repair generally involves a wider range of options, including

tight-fitting split sleeves, encapsulations, bolt-on repair devices,

and fibre-reinforced composite wraps.

Before the repair operation takes place – onshore or

offshore – a series of planning and operations are typically

required to determine the extent and cause of the damage,

site preparation and intervention, and planning of the repair

operation. It is important to assess the criticality and stability

of the damage and proposed repair techniques in a live repair

situation. Pipeline integrity, i.e. maintaining the safety, reliability

and efficiency of the pipeline should be at the centre of the

entire repair operation. Increasingly, advanced 3D nonlinear

finite element mechanical and thermal analyses are being

used for pipeline integrity assessment, which requires in-depth

knowledge of the tools available.

DNV-RP-F113 (2007) Recommended Practice (RP) is widely

referenced for the qualification of fittings and systems used for

pipeline subsea repair and/or modifications and tie-ins. The RP

includes aspects relating to the design, manufacture, installation,

and operation of such fittings and systems. The maintenance and

modification technology on offshore pipelines has developed

since the publication of the RP to accommodate deeper and

harsher environments, and to reduce downtime. Therefore,

a fast-track joint industry project (JIP) has been launched by

DNV GL to update this RP in order to capture the latest best

practices, experiences and expertise from the main providers

and operators of pipeline repair equipment and tools, and to

formalise criteria and procedures on pipeline subsea repair into

an internationally recognised standard.

Material considerations in welded live repair

strategies

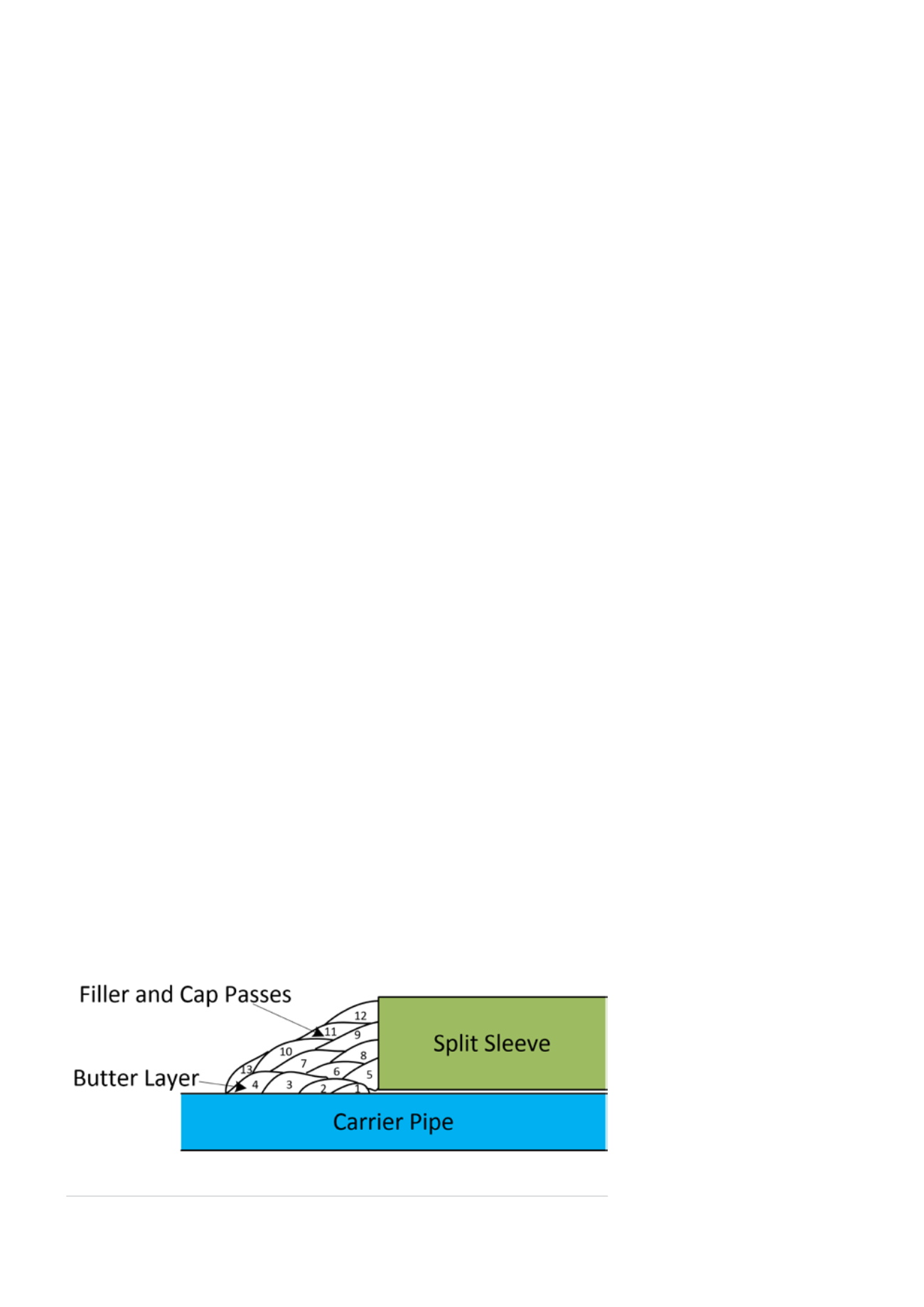

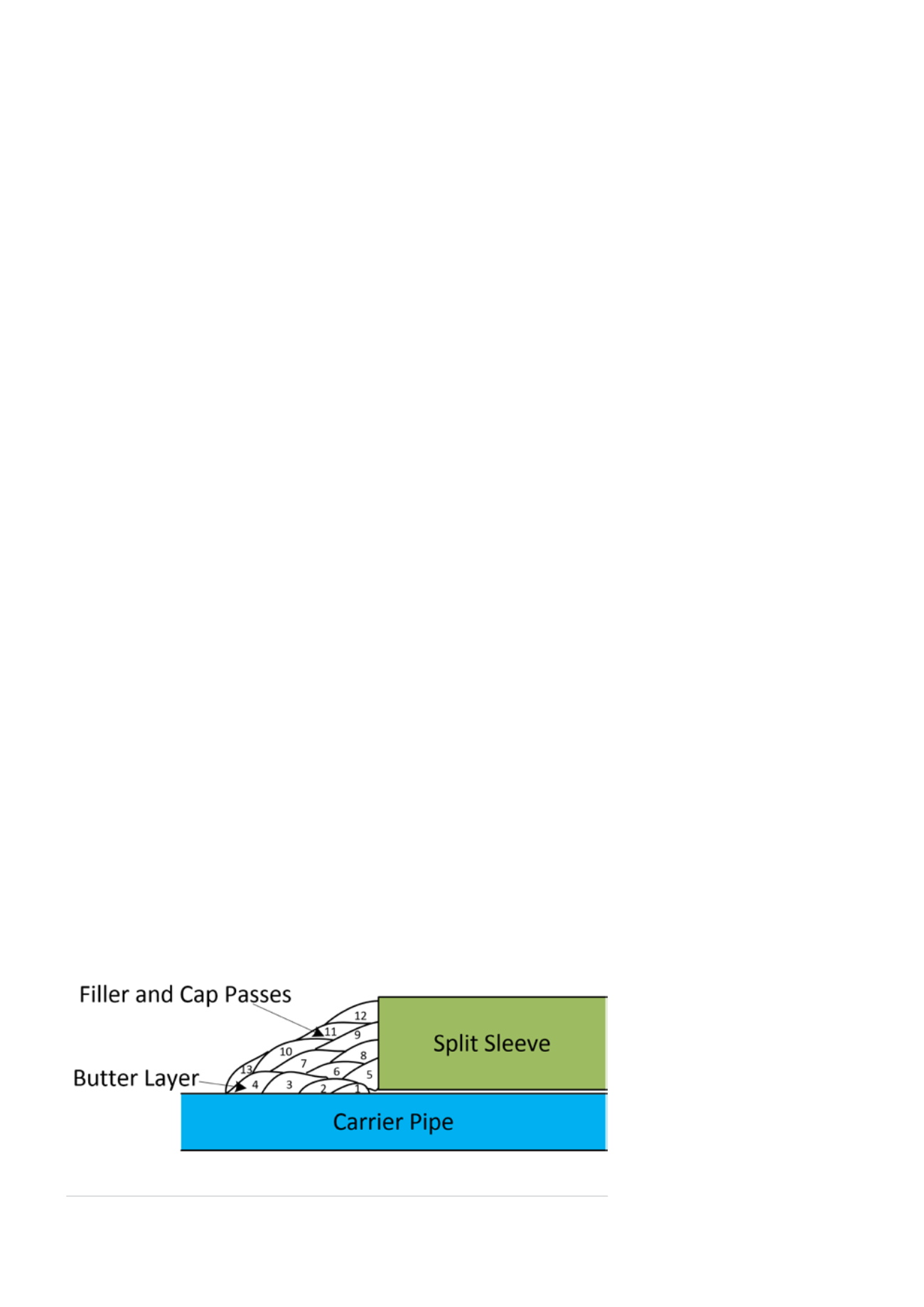

For all pipeline repair operations involving welded sleeves, the

circumferential welds attaching the sleeve to the carrier pipe

are the most critical. These welds are usually performed using a

one or two layer buttering before completion of the fillet welds

(Figure 1).

It is important that the pipe has a good weld-ability to

ensure that an acceptable HAZ hardness is obtained in view

of the forced cooling caused by fluid flow and the habitat

atmosphere and pressure.

Weld thermal simulations are usually performed to check

flow, required welding conditions, and preheating temperature.

To run such simulations, tools such as the Pipeline Research

Council International (PRCI) hot tap software is required. The

weld cooling time, defined as the time taken for the weld seam

and adjacent heat-affected zone to cool between 800 - 500°C,

can be estimated based on the welding parameters such as the

pipe temperature, flow velocity, pressure, pipe and sleeve wall

thickness. The maximum HAZ hardness can either be estimated

based on the weld cooling time value and the PRCI hot tap

simulation tool, or directly using the Yurioka formulae.

For hyperbaric welding conditions under high pressure and

HELOX atmosphere (diver assisted welding down to 180 m) or

remotely controlled GMAW processes (100% Ar down to

1300 m), additional cooling effect is experienced and the effect

of habitat atmosphere and pressure must be combined in the

weld cooling time computations.

For subsea pipelines designed and constructed to DNV-

OS-F101, there are restrictions on the steel carbon content, i.e.

0.12% weight and a typical Pcm value of 0.22 for a SAWL 450

grade pipe. These restrictions on the chemical composition

generally would allow acceptable HAZ hardness (325 HV10

for sweet conditions) to be met even for hyperbaric pipeline

repairs. For pipeline grades specified for sour conditions, such

as grade SAWL 450 S (suffix S for supplementary sour service

requirements), the maximum carbon content is more stringent at

0.10% weight.

A preferred practice for pipeline

sleeve repairs would be to select a

modern low carbon steel line pipe

material, either thermo-mechanically

controlled processed (TMCP) or QT

for the sleeve manufacture. This would

ensure weld-ability of the sleeve and

prevent high hardness in the sleeve

HAZ that usually depends on sleeve

thickness.

The above refers to repair welding

on subsea pipelines designed and

Figure 1.

Typical sleeve fillet weld shown with a one layer buttering deposited onto the

carrier pipe before completion of the root (pass five) filler and capping passes.

36

World Pipelines

/

MARCH 2016