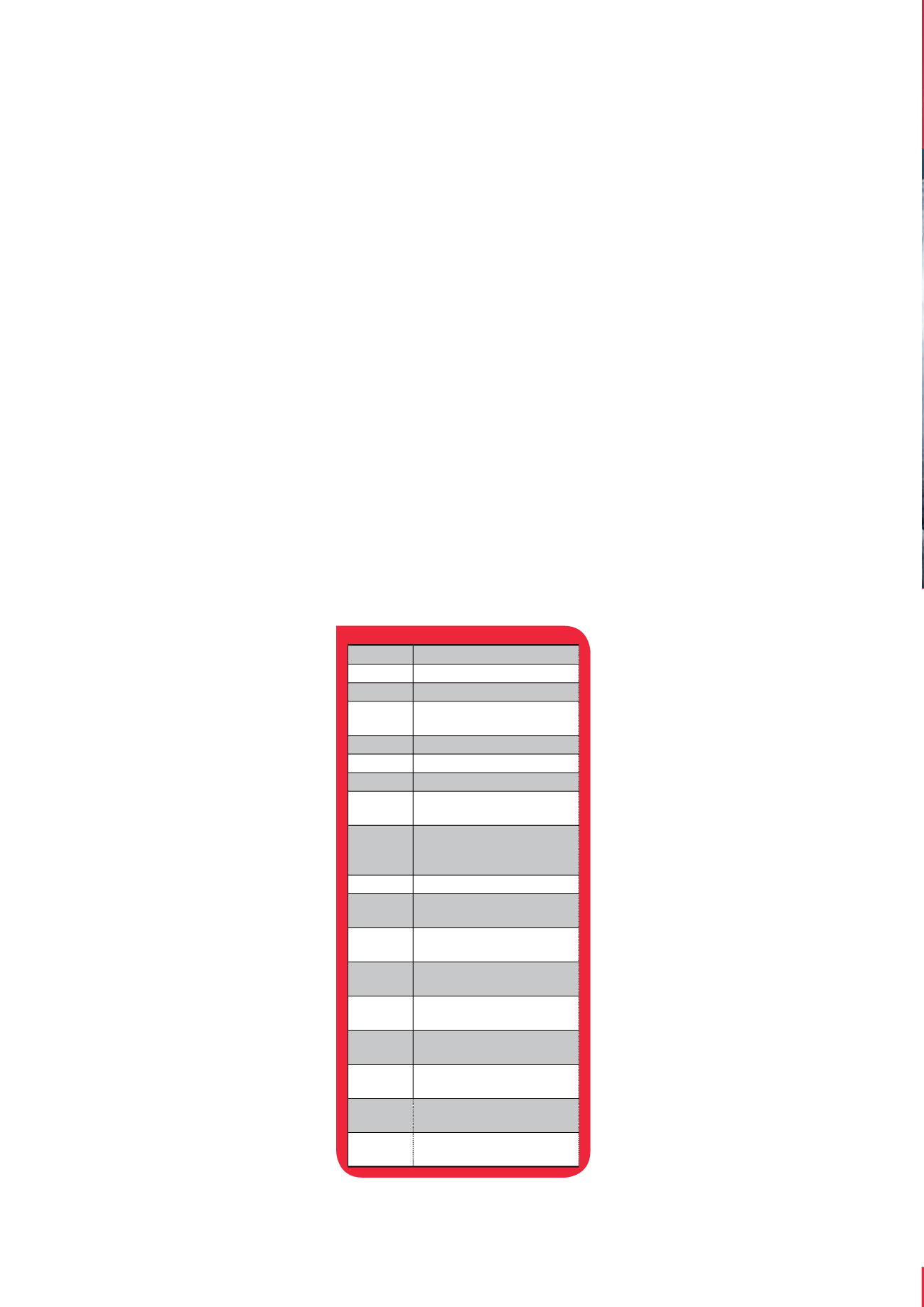

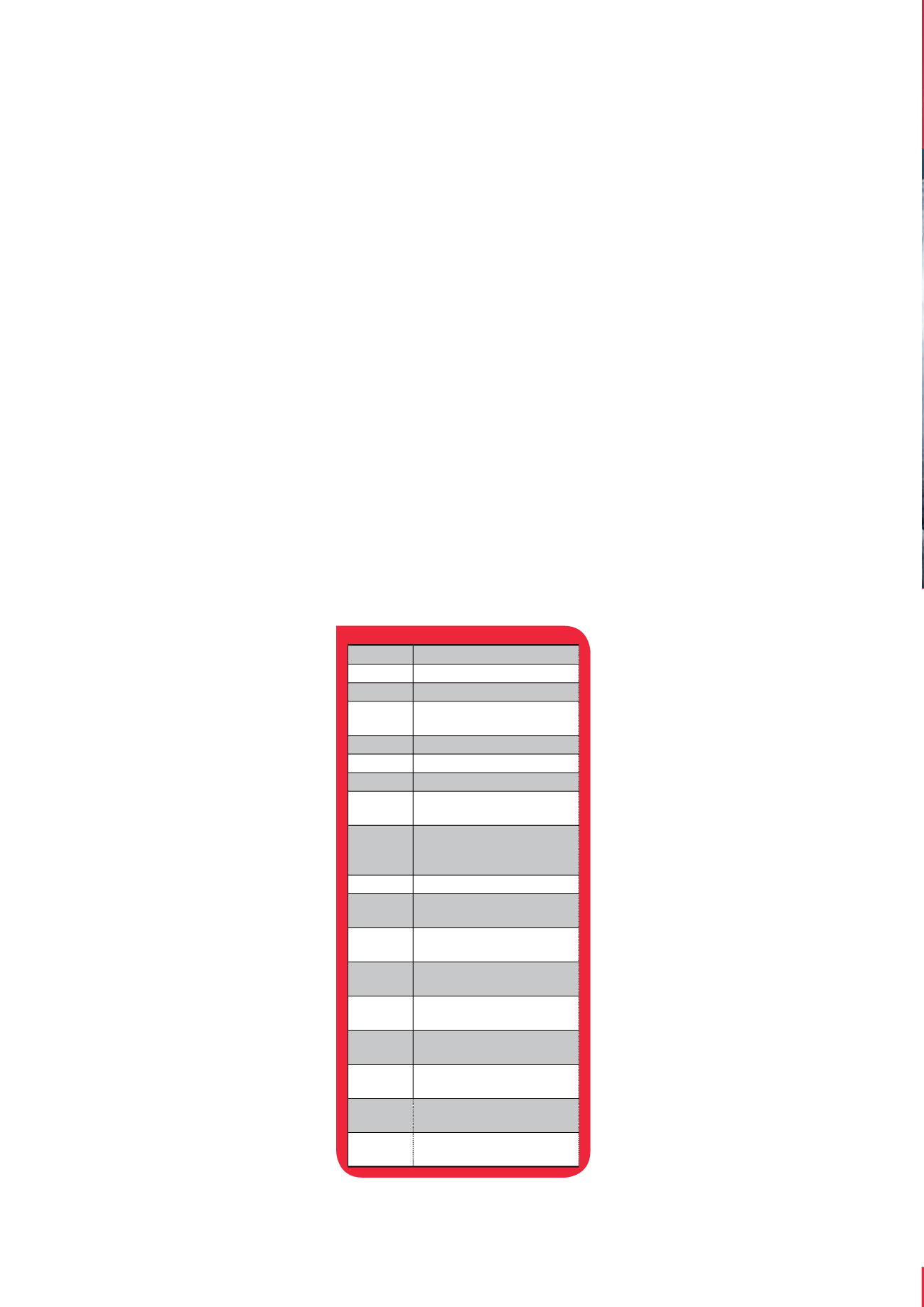

Key

ILI

Inline inspection

DA

Direct assesment

MOP

Maximum operating pressure

MIC

Microbiologically influenced

corrosion

CP

Cathodic protection

MFL

Magnetic flux leakage

UT

Ultrasonic testing

ECDA External corrosion direct

assessment

ECCDA External corrosion

confirmatory direct

assessment

IDCA Internal corrosion assessment

SCCDA Stress corrosion cracking

direct assessment

WG-ICDA Wet gas internal corrosion

direct assessment

DG-ICDA Dry gas internal corrosion

direct assessment

LP-ICDA Liquid petroleum internal

corrosion direct assessment

CP CIPS Cathodic protection close

interval potential survey

DCVG Direct current voltage

gradient

ACVG Alternating current voltage

gradient

ACCA

Alternating current-current

accentuation

Hydrotesting

Hydrotesting became common practice for pipelines in the

1940s. The process involves taking the pipeline out of service

and purging the product, then the pipeline is pressurised

above the maximum operating pressure (MOP) with the intent

to determine the ability to operate the pipeline at MOP.

While hydrotesting is still widely used today, there are several

drawbacks to the process. The water used in hydrotesting

is considered hazardous material after being used, meaning

owners incur the additional risk and cost associated with

disposing of the water after testing. The information gained

from the test is also limited in that it provides no information

of the actual condition of the pipe, coating or surrounding

environment.

Hydrotesting can also promote internal corrosion of

pipelines, especially if the water used is not properly treated

for microbiologically influenced corrosion (MIC) and chlorides.

Internal corrosion usually occurs if the pipeline is not

properly cleaned and dried after the test. Hydrotesting can

also result in pressure reversals, which worsen the integrity

of the pipeline.

1

Finally, the pipeline may be required to be

out of service for a significant amount of time, resulting in a

significant loss of revenue.

ILI tools

ILI tools – which are commonly referred to as smart pigs

– were developed in the 1960s and

commercialised in the 1970s. These tools

are designed to survey the conditions

of the pipeline wall with limited

disruption and can identify and quantify

the corrosion and cracking in steel

pipelines.

2

Magnetic flux leakage (MFL)

and ultrasonic testing (UT) are common

ILI tools used widely by owners today.

ILI is a significant part of pipeline

integrity management, and promote

safe, efficient and cost-effective pipeline

operation.

2

However, it is important

to remember that ILI is just a subset

of a family of inspection tools used

to verify pipeline fitness for service.

As with any inspection technology, ILI

tools have a threshold for detection –

the tools are unable to reliably detect

anomalies that are below their design

specifications’ detection ability. Also,

internal pipeline inspections are primarily

reactive, requiring the damage or wall

loss to occur before defect detection is

possible.

DA management

The most recently developed solution

for pipeline integrity management is

DA, which is a structured, iterative

integrity assessment protocol used by

pipeline operators to assess and evaluate the integrity of their

pipelines.

Adoption and demand for DA is increasing in modern

integrity programmes due to more stringent industry

regulations, ageing pipeline networks, limitations of alternate

inspection techniques, and the fact that roughly 70% of

pipelines within North America are difficult to pig. DA surveys

provide pipeline owners with important information on both

the pipeline’s condition and its surrounding conditions, both

of which can lead to degradation and eventual failure.

The stages of DA

It should be noted that geotechnical, dent, and buckle threats

are not specifically addressed with any of the DA techniques.

All DA protocols are four-step iterative processes that include

a pre-assessment, an indirect inspection, a direct examination

and a post-assessment. Inspections involve the integration of as

much pipeline available integrity data as possible, which includes

physical characteristics and operational history, historical and

multiple indirect inspections, and direct pipe surface examinations.

In the pre-assessment step, historic and current pipeline

data is collected to determine whether DA is feasible, define

DA regions, select indirect inspection tools and determine if

additional integrity data is needed.

The second step in DA methodology involves the use

of non-intrusive and aboveground techniques. These tools

assess the effectiveness of the coating

and CP for pipeline external corrosion

assessment (EDCA and ECCDA), and

predictive modelling, or critical angle

calculations for pipeline internal

corrosion assessment (ICDA) to identify

and define areas susceptible to internal

corrosion.

For EDCA, the state of CP, coating

and soil resistivity are critical factors

in determining high-risk areas. For

ICDA, fluid flow, mass transfer,

solid accumulation, mineral scales,

corrosion products, and MIC are

critical components.

3

For stress

corrosion cracking, critical factors

include operating stresses, operating

temperatures, distance from a

compressor station, age of the pipeline,

and coating type.

The direct examination step involves

the analysis of pre-assessment and

indirect inspection data to select sites

for excavation and examination of

pipe surface. This process validates the

inspection data and provides a first-

hand evaluation of the pipe surface and

surrounding environment.

Finally, the post-assessment phase

involves the analysis and integration

of integrity data collected from the

42

World Pipelines

/

MARCH 2016