Coatings

&

Bill Sante, Axalta Coating

Systems, USA

The biggest threat to the integrity of

pipeline coatings (in the plant and/or in the

field)

Axalta Coating Systems has 150 years of experience in coatings,

a third of which as an active player in the pipe coating market,

so is familiar with the threats to the integrity of pipeline

coatings. There are a few of them, and some are more common

than others. First, damage to the coating during installation

(handling, dragging or bumping) or operation of the pipe tends

to yield the largest issues.

However, there are a few coating technologies and other

alternatives on the market to help offset this type of damage.

For instance, Axalta offers abrasion resistant overcoat (ARO)

solutions or numerous combinations of dual layer options,

which are specifically designed to offer increased protection.

Additionally, pipe coatings utilised in improper operating

conditions can result in issues such as hot spots, leaks, etc.

Another threat to the integrity of pipeline coatings is the poor

or inadequate application of the coating, whether it is in the

field or a controlled environment. And finally, a weak shielding

mechanism, or no cathodic shielding mechanism at all, can lead

to accelerated corrosion in some cases.

Coatings for high pressure, high

temperature pipelines

Coatings for high pressure/high temperature pipelines are

requests that coating manufacturers are hearing more about,

and are generally taking quick action in order to address

customers’ needs. Axalta Coating Systems is no exception.

The pipeline market is asking for both external and internal

coatings that can resist higher temperatures. The rise in

standards is due to the industry being forced to drill deeper

shafts, which require directional drilling in order to reach

the wells. The location of these wells are in more rigorous

environments, with temperatures reaching

>

150˚C and pressure

levels of 10 000 psi. The Nap-Gard portfolio from Axalta

currently offers external coating systems that have been used

on pipelines operating at 150˚C and up to 180˚C. The most

challenging part of developing high-temperature coatings

is getting agreement from the industry on defining what an

external coating needs in order to pass and be considered ‘a

qualified coating’ for higher operating temperatures. Axalta

will be releasing a new internal high temperature coating in the

latter part of 2016 to meet the needs of higher temperature

resistance.

Which convention, conference, standards

and guidance are of most relevance to the

pipeline coatings industry?

Axalta Coating Systems continues to have a global presence

at NACE International, AMI organised pipeline and field joint

coating conferences, which bring together many talented

professionals to discuss issues and solutions within the industry.

On a regional level, events such the NAPCA and NACE have

been very beneficial for networking and learning from suppliers

and customers in North America.

In all regions of the world, the industry specifies the

pipe coating standards as defined by the Canada Standards

Association (CSA) and ASTM International. These two

organisations define the majority of the standards and testing

methods, and as such we of course work to meet them. For

example, Axalta’s Nap-Gard portfolio adheres to the industry

standards for impact resistance, bending, elongation, hardness

and cathodic disbondment, as defined by CSA and ASTM

International.

Biggest challenge to the pipeline coatings

industry in 2016

The challenges the pipeline industry in 2016 will face will

most certainly revolve around the soft demand for pipeline

construction, which is directly impacted by falling crude oil

pricing. Additionally, cost pressure by end-users and pipeline

owners will cascade through the value chain to ensure that all

suppliers remain price competitive.

From a technology standpoint, the challenges will be

the continuing need for high-temperature and pressure-

resistant coatings in new pipeline construction. These elevated

temperature and pressure scenarios are evident in every region

of the globe where the industry continues to drill further

horizontally and deeper into the ground to reach the wells and

shale deposits. Axalta is addressing these needs by developing

internal and external coatings, which will have capabilities of

withstanding temperatures in excess of 200˚C and pressure of

10 000 psi.

Note

Bill Sante, Global Director, Functional Coatings for Axalta Coating Systems.

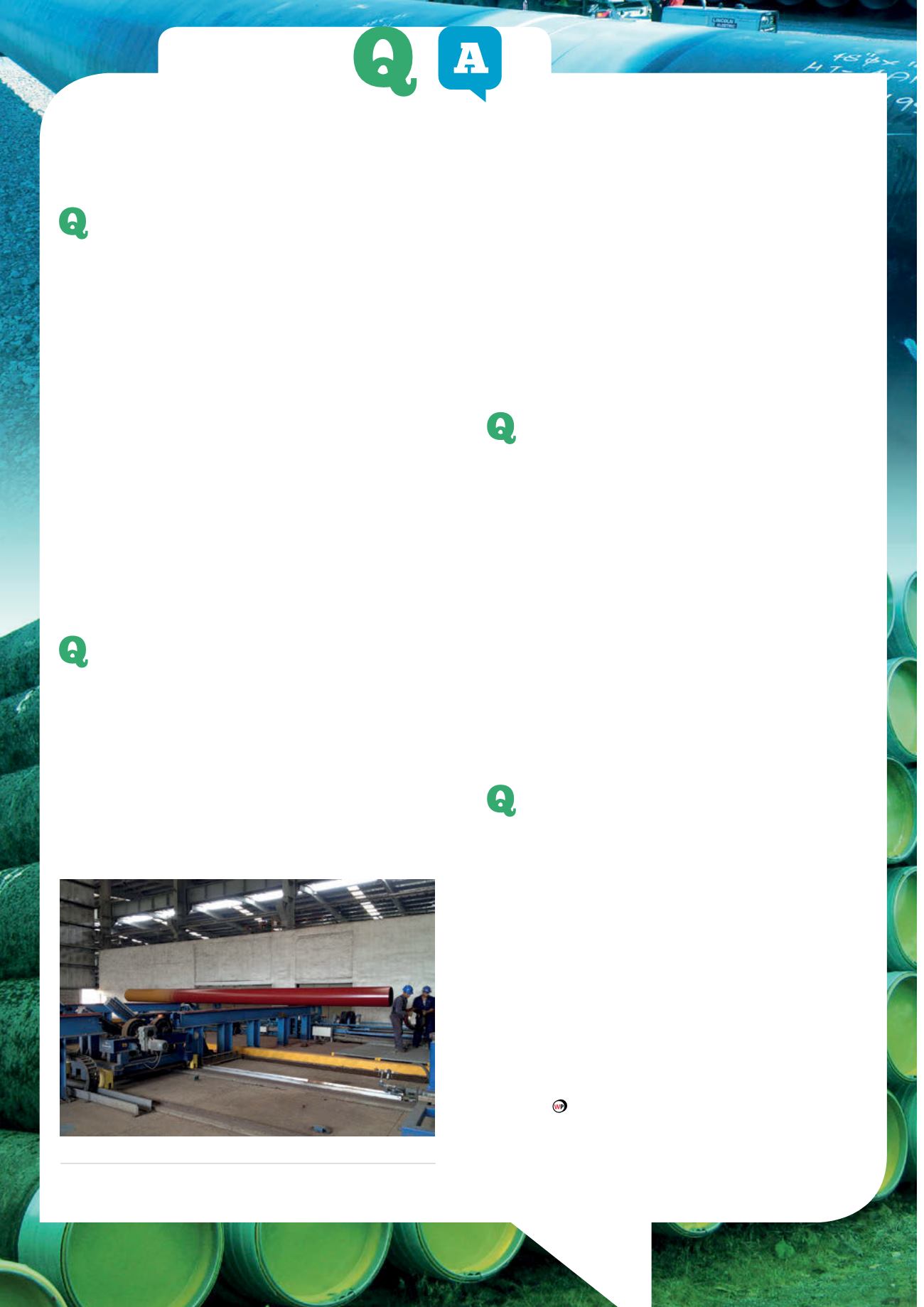

Figure 1.

Axalta double layer FBE coating.

52