design. SNC-Lavalin proposed three compressor units with the

following configuration, subsequently installed on common

header piping:

)

)

Driver: Waukesha 16V275GL+.

)

)

Rated bhp: 4835 bhp at 1000 RPM.

)

)

Compressor: Ariel JGC/6.

)

)

Cylinders: 12.5 CM, 9.75 CM.

)

)

Stages: two.

)

)

Suction pressure: 250 - 750 psig.

)

)

Discharge pressure: 1250 psig.

)

)

Design flowrate: 167 million ft

3

/d per unit.

The compressor frame, cylinder and driver combination

was selected to maximise the flowrate across the operating

range. SNC-Lavalin conducted an on-skid pulsation analysis of

the compressor units and proposed an optimised vessel design

that was within API 618 (5

th

edition) pulsation and mechanical

guidelines. At the time of the on-skid analysis, the off-skid plant

piping layout was being designed by the EPC firm and was not

included in the SNC-Lavalin scope of evaluation.

Plant design with off-skid piping

A pulsation study was conducted on the off-skid plant piping by

another firm. Due to higher than allowable pressure pulsations

observed in the off-skid piping, multiple restriction orifice plates

were recommended. The parasitic losses associated with the

additional orifice plates would result in a loss of 17.6 million ft

3

/d

station throughput and a corresponding revenue loss of

US$15 million/y (calculated at US$2.27 per million Btu) for the

end user.

The end user requested SNC-Lavalin to review the plant

design and conduct an independent acoustic analysis. SNC-

Lavalin conducted the plant header study and confirmed that

the pressure pulsation in the plant piping was higher than

allowable. Using orifice plates in the piping would have reduced

pulsation, but at the cost of efficiency and capacity. As a result,

SNC-Lavalin looked for other methods to reduce pulsation

while maintaining the desired flowrate of the plant. The

pulsation in the piping was amplified due to reflection points

in the off-skid piping. Multiple compressor units on a common

header also generated higher pulsation in the header and the

unit discharge lines. Since changing line sizes or layout was cost

prohibitive, it was necessary to filter the pulsation frequencies

of individual units without creating additional pressure loss.

SNC-Lavalin designed two additional off-skid volume

bottles per unit (one vessel on each stage discharge line). The

location of the vessel on the off-skid piping was optimised to

get the best acoustic response. The size of each vessel was then

optimised to reduce the line pulsation within API 618, 5

th

Edition

guidelines (Figure 2 and 3). The calculated pressure drop due to

secondary off-skid volumes was minimal.

Conclusions

Development of the shale resources with variable or declining

well pressure requires compressors to operate over a wide

operating range. Maximising flowrate throughout the operating

range extends the profitability of the compression asset over its

lifecycle.

Traditionally, pulsations generated by the compressor are

controlled by utilising large pressure vessels and restriction

orifice plates. Large discharge vessels are not desirable, as it

raises the centre of gravity of the compressor frame, resulting in

increased mechanical vibrations.

Restriction orifice plates control pressure pulsation in the

pipeline but result in a permanent pressure drop in the system.

Parasitic load due to pressure drop should be minimised, since it

has an inverse correlation with the compressor flowrate.

Optimising the compressor unit on-skid vessel and piping

design is not enough to ensure maximum throughput. A

complete plant header study is needed to evaluate methods to

reduce pulsation while maintaining the desired flowrate of the

plant.

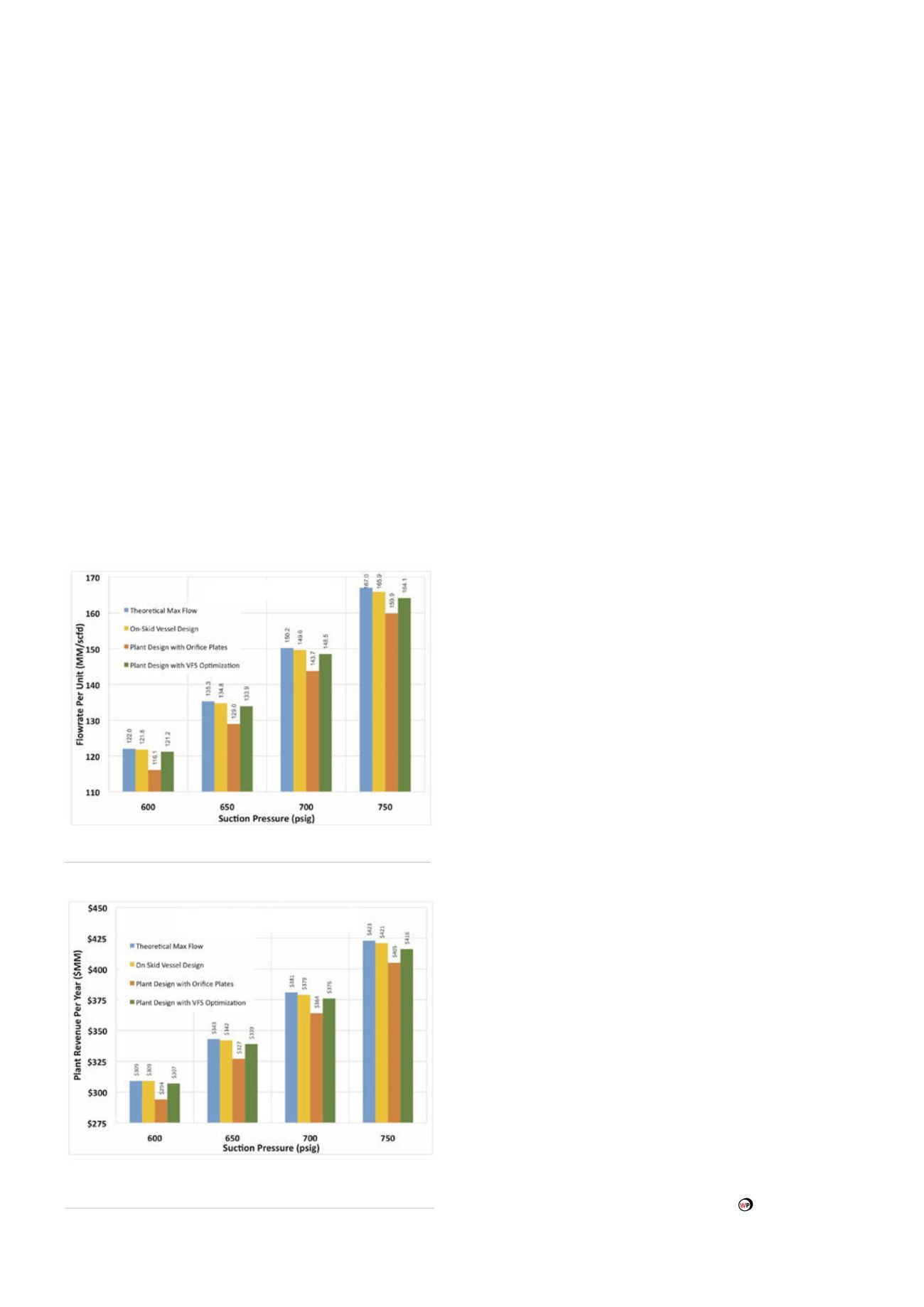

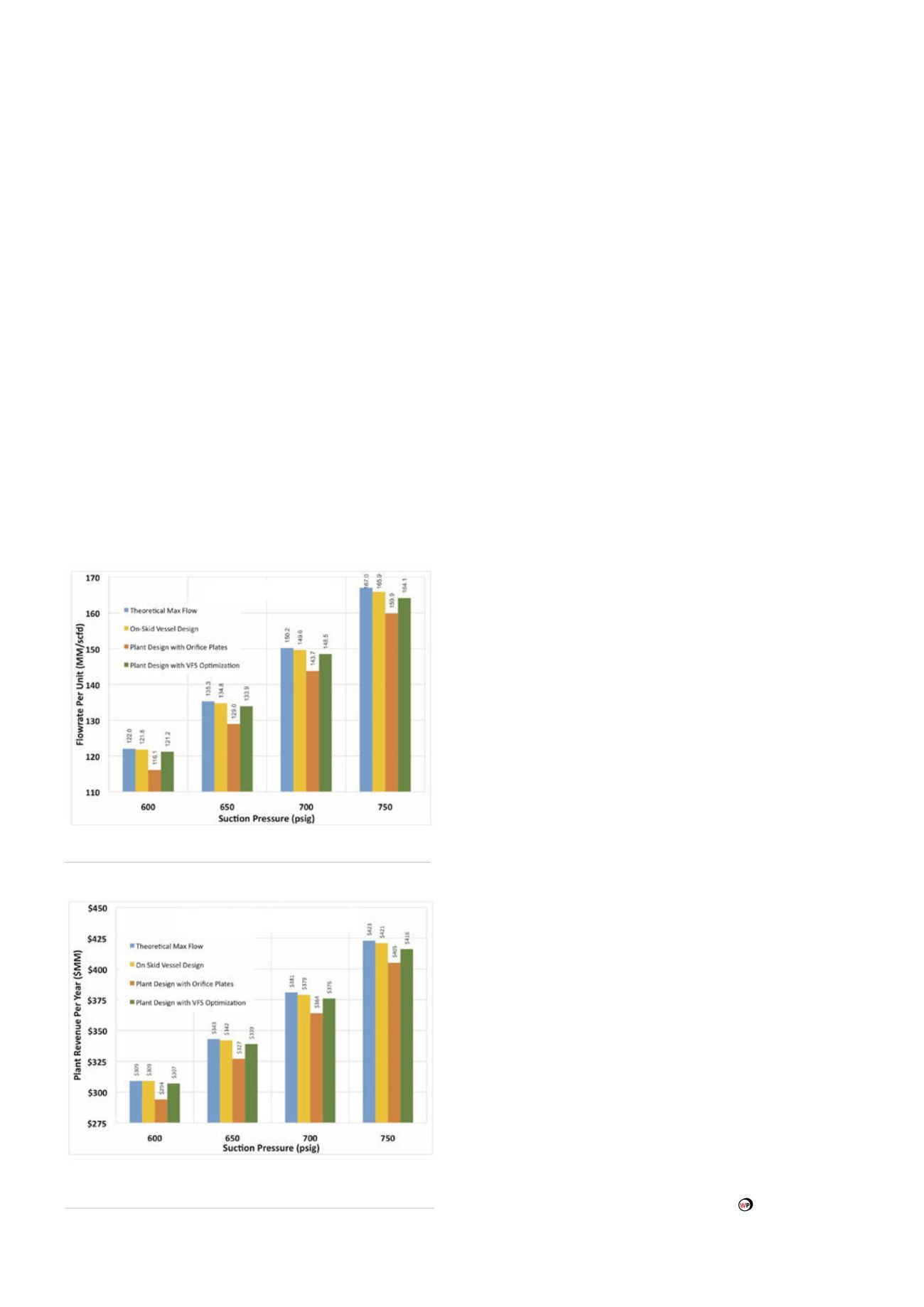

In the case study presented in this article, SNC-Lavalin

designed two additional off-skid volume bottles to reduce

pulsation in the plant piping within API 618 (5

th

edition)

guidelines. The design optimisation conducted by SNC-Lavalin

avoided a flowrate loss of 12.6 million ft

3

/d and corresponding

revenue of US$11 million/y (Figure 4 and 5).

Figure 4.

Flowrate per unit.

Figure 5.

Plant revenue per year (US$ million): calculated at

US$2.27/million Btu.

56

World Pipelines

/

MARCH 2016