Coatings

&

Frits Doddema, Seal For Life

Industries, the Netherlands

The biggest threat to the external integrity

of pipeline coatings (in the plant and/or in

the field)

It is ageing pipelines and the state of coatings and back-up

by cathodic protection (CP) that pose the biggest threat to

pipelines’ external integrity. Stress corrosion cracking (SCC)

induced by alternating current (AC) or direct current (DC),

and stray current inflicted corrosion issues are also a concern.

When is it time to rehabilitate? Specific electrical resistance

in Ohm/m

2

is a good indicator. The coating industry should

avoid misleading terms like ‘non shielding’. The purpose of the

old and rehab underground pipeline coating is to provide a

barrier, a shield and to avoid the creation of micro-cracks in

the coating. The specific electric insulation properties of the

coating should be enough not to allow a CP current to pass

through the coating. It means the coating should have low

moisture absorption and a high electrical resistance.

R&D spend on coatings for oil/gas

pipelines

Pipelines are being developed worldwide to meet rising

demands for energy, and pipeline integrity is being studied

to reduce loss in transmission and to handle increasingly

hostile environments. From cement composites to fusion

bonded epoxies (FBE), self-healing polymers and layered

polyolefin, new coating materials have been produced and

are undergoing extensive trials in the laboratory and infield

testing for internal pipe coating usage and external for field

application.

Pipe coating companies are undertaking much of the

new research. Some pipe coaters are looking at alternative

adhesion promoters for polymeric coatings in wet sour gas

conditions. Pipelines in rough terrain, like blasted out rock

trenches, require additional mechanical protection. New

rockshield or thin layers of fibre-reinforced cement solutions

have been developed. Also, excellent work is being done on

cementitious-based linear anode solutions.

Coatings for high pressure, high

temperature pipelines

From the perspective of polyolefin-based coating solutions

for high temperature pipelines, we have seen a shift to

polypropylene. Re-introduced solutions like irradiation

beamed mechanical protection materials based on polyolefin

has caught attention. For field application and in the shop,

pipe can be coated with these cold applied or heat shrinkable

sheets in order to protect the anticorrosion coated pipelines.

The irradiation beamed materials and adhesives withstand

the 120˚C conditions. These materials offer a longlife 3D

crosslinked advantage over extruded polylefins for thermal

stressfull application and services.

Coatings for offshore pipelines

Corrosion control for offshore pipelines is typically

achieved with a combination of pipe coatings supported with

CP to cover coating holidays or defects. The best and most

practical measures that can be taken to prevent damage to

the corrosion control systems depend on the type of pipeline

and the pipelay method. The following general guidelines may

prove useful:

)

Weight-coated pipelines.

)

Reel laid pipelines.

)

Conventional pipelay (S-Lay).

)

Conventional pipelay (S-Lay)

<

200 ft seawater.

)

J-Lay pipelines: bottom or controlled depth towed

pipeline installation.

In case of coating repair or damage repair, the company

offers subsea applicable systems to prevent corrosion,

insulation and sealing.

Combining technologies for corrosion

protection

Seal For Life Industries encapsulates five established

and leading brands in the area of dealing with corrosion

prevention and control. We operate worldwide across many

different industries and in many different markets – which is

in no small measure thanks to the innovative capabilities of

the five brands within our group, each of which has its own

specific disciplines.

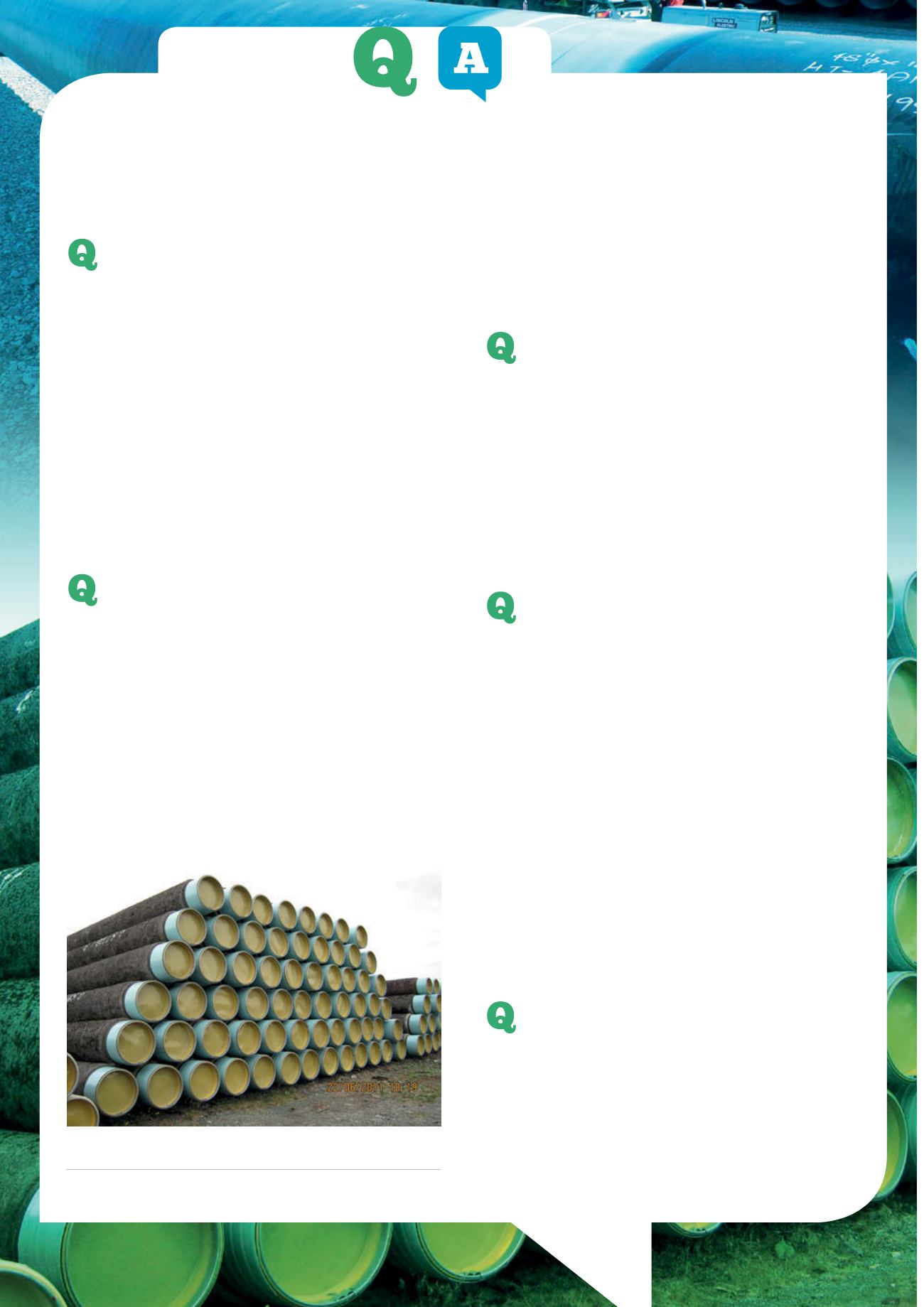

Figure 1.

Statoil pipeline storage by Dhatec EndCaps, Stopaq

Sealing and Corect VPCI provided by Presserv AS.

46