Coatings

&

overall coating cycle time by almost 80% using this automated

process.

The successful coating of inside diameter field joints,

particularly smaller pipe sizes, can pose certain challenges.

It is a difficult process to effectively clean, blast and coat

field joints that cannot be seen or reached by conventional

equipment and workers. As the industry increasingly demands

internal field joint coating, especially on horizontal directional

drill (HDD) pipelines and sour service lines, Aegion Coating

Services engineers and implements its own proprietary robotic

technology. With this technology, untethered robotic trains

are remotely guided up to 1000 m into the pipeline using the

latest telemetry transmissions. These robotic coating machines

are operated remotely by specialist technicians and perform

surface preparation, coating and inspection activities with the

aid of live video from cameras built into the robotic train. The

protective coatings of choice are typically either FBE or liquid

epoxy coatings. Once the inside diameter field joint is cured,

the same robots inspect the work to assure operators these

field joints are defect-free and coated to specification.

The field joint is considered the ‘weakest link’ during

pipeline construction, making coating a critical operation.

Combining internal and external automated robotic

technology allows pipeline operators to control pipeline

surface preparation, coating application and inspection

involved in this process.

Coatings for offshore pipelines

Despite project delays amidst low oil prices, deepwater

production expenditure is expected to increase by 69%

according to a report by global energy consultancy firm

Douglas Westwood.

1

Major growth regions including Africa,

Latin America and North America, collectively account for

approximately US$173 billion out of the overall US$210 billion

expected to be spent from 2015 - 2019. This increase is

believed to be spurred by maturing shallow water fields that

are driving exploration to more challenging frontiers such as

the Arctic and deepwater environments.

Thermal insulation coating is a key tool in a pipeline

engineer’s toolbox to help ensure that flowlines and risers

operate reliably in deepwater environments. These flow

assurance coating systems are applied throughout the length

of the pipeline except for the girth weld field joint section,

making application of a compatible insulating field joint

coating necessary during the pipeline construction process. As

deepwater developments increase in scope and quantity, so

will demand for high-performance deepwater pipeline coating

systems that can withstand design temperatures upwards of

150˚C and pressures surpassing 10 000 psi. Aegion Corporation

has responded to this by partnering with Wasco Energy to

construct a new Bayou-Wasco Insulation (BWI) pipeline facility

in New Iberia, Louisiana. This new facility allows the company

to service the Gulf of Mexico deepwater market along with

pipeline coating projects in Latin America and the Caribbean.

Flow assurance systems generally rely on syntactic and

foam polypropylenes, polyurethanes and epoxies. However,

trends indicate the current materials commonly used for

insulation purposes may not satisfy future deepwater pipeline

thermal and mechanical requirements. Deepwater pipelines

requiring thicker insulation coatings will pose challenges for

marine construction contractors during construction, for

instance field joint coating stress cracking failures during

pipelay. Pipeline installers have also expressed concerns

regarding the large field joint coating insulation equipment

footprint when operating on a barge or spoolbase that

is already limited in space. When lay vessel day rates run

into the hundreds of thousands of dollars, compounded

by the cost of operating in a low oil price environment,

according to Michael Surkein of ExxonMobil Development

Co., there is a “significant economic incentive to eliminate

the offshore pipeline field joint”.

2

Pipe coating manufacturers

and applicators must therefore reassess the materials and

application methods that are traditionally used to ensure

that field applied deepwater coating solutions also do not

contribute to cost overruns in increasingly ‘lean’ times.

Coatings repair and rehabilitation:

inspection, repair methods, testing

Rehabilitation of exterior and interior coatings can frequently

extend the life of a pipeline in a cost-effective manner. Old or

failing coatings can be located by various means. For piggable

pipes, inner diameter (ID) coatings can be directly observed.

For outer diameter (OD) coatings, corrosion engineering

companies like Corrpro can detect failures in coatings by

monitoring changes in CP current levels. Once failures have

been pinpointed, the rehabilitation process can begin.

For OD coating rehab, excavation is required. Once the

area is properly shored up, the rehab contractor begins by

removing the failed coating. Best practices recommend

complete coating removal followed by abrasive cleaning of

the substrate, however some clients prefer to simply abrade

the existing coating in order to save time and money. In cases

of badly disbonded coating, this cost-saving measure is simply

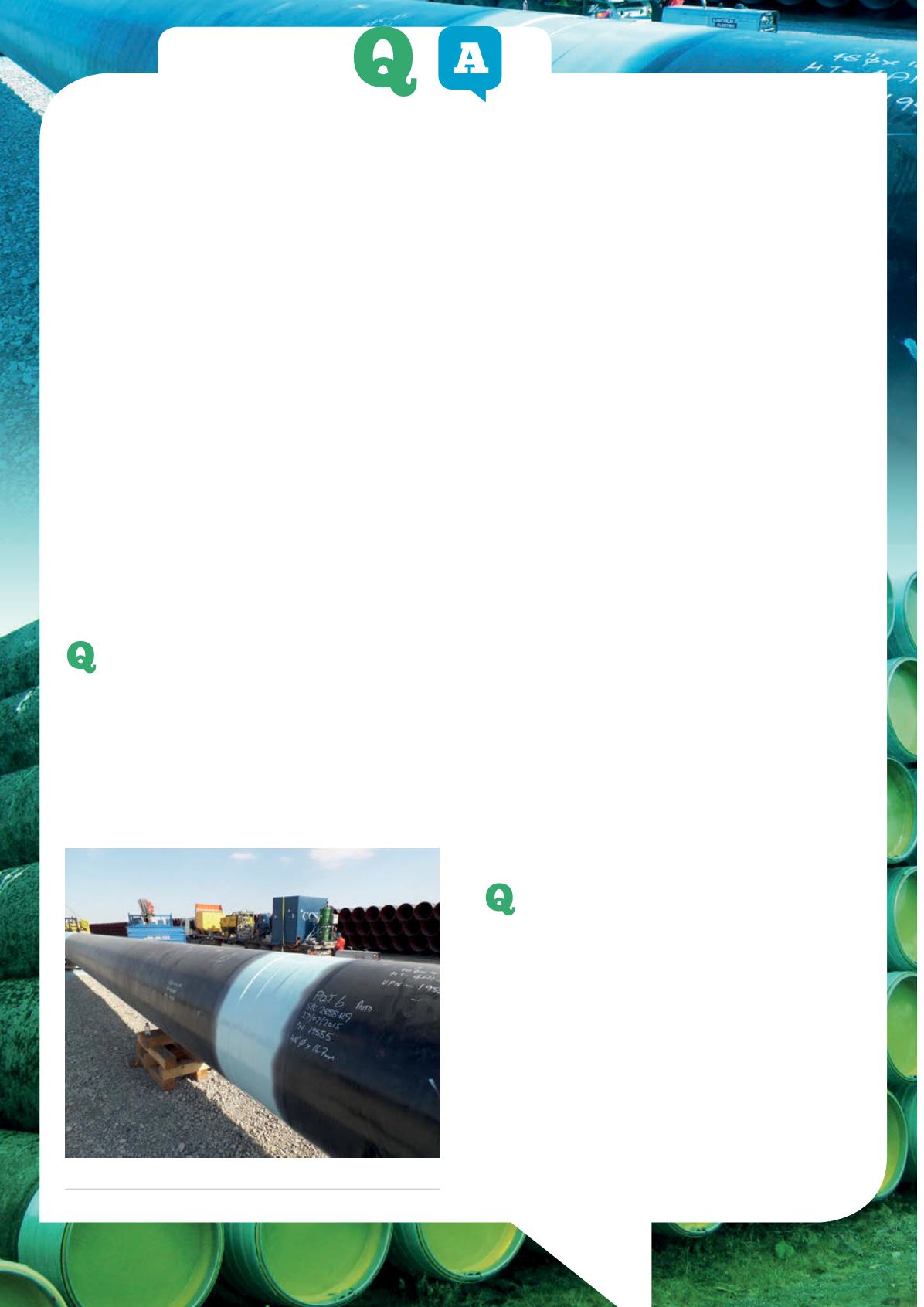

Figure 1.

Liquid coated joint.

50