valves to stick in open (Figure 3). Known as steam contamination,

this can also cause an unsafe condition.

In lube oil systems, where critical instrumentation shares the

same oil system as the steam turbine, contamination such as

particle or condensate can be introduced to the valve’s actuator

(Figure 4). This can cause the valve’s actuator to stick open and

not activate when an emergency trip is required, thus causing an

unsafe condition.

Theory of operation

Traditionally, trip, trip-throttle and/or swing disc non-return valves

are reset and allowed to be actuated once positive minimum

oil pressure is established at the valve. The loss of oil pressure –

which is initiated by either a solenoid or mechanical trip valve

– will cause the trip or trip-throttle valve to immediately close in

less than 0.5 or 0.3 secs, depending on the valve type.

Steam turbine trip systems

Steam turbine trip systems come in a variety of options. Over the

years, Steam turbine OEMs have designed their own trip systems

that can typically be classified as mechanical or electrical trip

systems. Both are based on speed and work within a specified

range.

Mechanical trip systems can be a simple spring-loaded plunger

that triggers a trip or flyweights that trigger the mechanical trip.

The trip can be caused via linkage or the loss of oil pressure to

the trip-throttle valves, which causes those valves to immediately

shut off steam to the steam turbine.

Electronic trip systems incorporate an electronic over-speed

device that monitors the speed of the steam turbine. Once the

electronic over-speed device senses a condition, a signal is sent to

deactivate the solenoid trip valves. Similar to the mechanical trip

system, these solenoid trip valves open, causing loss of oil pressure

to the trip-throttle valves, which in turn causes those valves to

immediately shut off steam to the steam turbine.

Legacy product line

Typical legacy product lines can include: latch type, oil operated

and swing disc non-return valves. Latch type valves (Figure 5) are

based on 1940s technology and use low pressure oil, either from

the steam turbine or lube oil skid, to allow the end user to reset,

open and close the valves.

Latch-type valves are typically used in API 611 and other

general-purpose steam turbine applications. These valves trip

in less than 0.5 secs. The oil-operated valve was released in

the early 1980s and uses a minimum of 100 psig to reset and

actuate this type of valve. The benefit of this type of valve is the

ergonomically designed human interface, higher trip speed, 4 - 10

times closing force, and back-seated design (eliminating steam loss

when the valve was in the open position). Typically used in API

612 and other special purpose steam turbine applications, the oil

operated valve trip time is less than 0.3 secs.

Swing disc non-return valves are used on induction/extraction

steam turbines and are used to prevent the reverse flow of steam

in a controlled way. The activation on the swing disc non-return

valves work to assist valve closure, as long as steam is flowing in

the direction opposite to its designed flow direction.

Note that the steam turbine trip system is not taken into

account when calculating the trip speed for the valves above. The

trip time is measured from the start and stop of the valve disc

(piston).

Figure 2.

Environmental conditions can cause valves to appear

as if they were sitting on the bottom of the ocean floor.

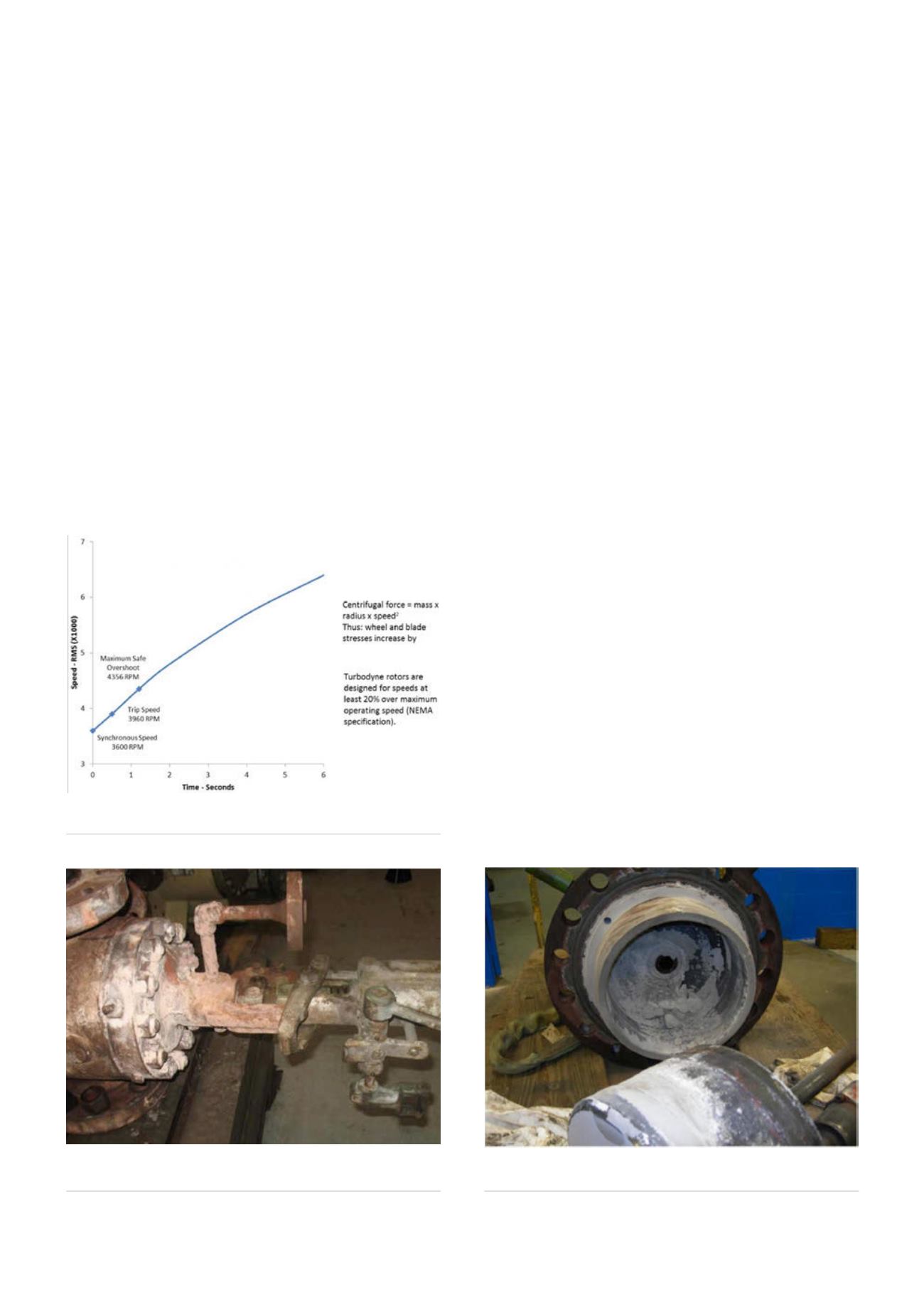

Figure 3.

Phosphate deposits resulting from steam boiler

carryover.

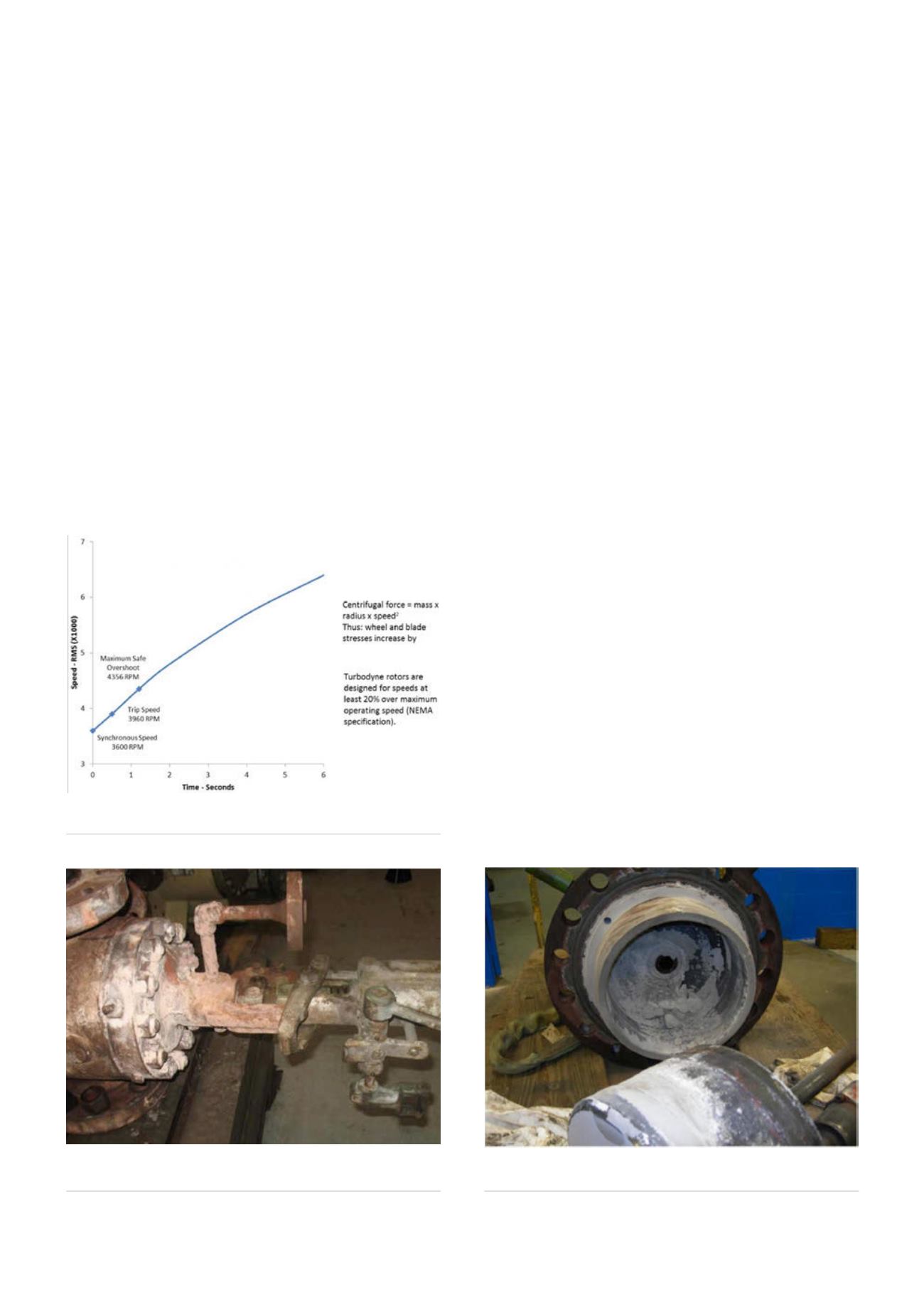

Figure 1.

Simplified acceleration curve for a typical turbine

generator.

58

World Pipelines

/

MARCH 2016