The updated 2014/68/EU PED regulation will take effect in

July 2016. As the first step in moving towards the implementation

of the updated directive, the requirements of the PED were

updated in June this year, the first change to the regulation in

17 years.

What is the PED?

The PED is an EU directive that originally came into force in

1997 (PED 97/23/EC) and applies to the design, manufacture

and assessment and assemblies of pressure equipment, with

a maximum allowable pressure greater than 0.5 bar. The PED

provides guidelines for conformity rather than a strict set of

rules, and sets out the standards for the design, manufacture,

testing, and conformity assessment of pressure equipment in the

European market.

Equipment that complies with the PED is certified with a CE

marking, providing assurance that certified pressure equipment

used in the European Economic Area (EEA) is safe and of sufficient

quality. The requirements of the directive are common to all

states within the EEA, and so all equipment in compliance

with the PED can be sold and used anywhere within the EEA.

This promotes the free movement of goods, and ensures that

compliance is as quick and efficient as possible.

Essentially, the PED requires the level of hazard of pressure

equipment to be assessed and classified into one of five

categories, which cover the entire spectrum of applications.

Equipment deemed to be more hazardous requires more extensive

evaluation of the safety and quality assurance required during the

design, manufacture and testing of the equipment.

The directive applies to any equipment within the scope

defined by the regulation, regardless of application, and also

applies to certain safety equipment designed to protect pressure

equipment from the allowable limits being exceeded. This

includes equipment that is designed to correct or shut down

operations, including pressure and temperature switches, and

pressure limitation devices, such as safety valves.

The PED has a wide range of conformity assessment modules

that define the criteria for design and inspection, as well as the

requirements for documentation. The risk factor of the product

is categorised by either the state of contained fluid, the stored

energy, or the hazards associated with the fluid in the product.

Once this has been determined, the relevant documentation

can be complied and evaluated. For those unfamiliar with

the requirements of these categories, such as companies or

contractors that are new to the sector or entering the European

market for the first time, this can be a confusing and time

consuming process. Knowing where to start and which questions

to ask is key to getting this process right and achieving compliance

efficiently.

Whose responsibility is the PED?

Everyone within the supply chain of pressure equipment has

a responsibility to ensure that only compliant, safe equipment

reaches the marketplace. Whilst some will have a higher level of

responsibility than others, everyone involved in supplying pressure

equipment will have a role to play. Changes to the PED impacts

the whole supply chain, including manufacturers, importers and

distributers of pressure equipment.

One of the key links in this chain are the engineers who

plan, install and maintain pipelines, as the design of pressure

equipment and pressure systems inevitably requires experienced

and knowledgeable experts. As all relevant equipment, plant

and systems within the EEA have to comply with the PED, it is

essential that engineers have at least a basic understanding of the

requirements of the PED and how it applies to their operations,

particularly as it is generally the engineer’s responsibility to

determine the hazard category of each particular equipment item

and system.

What is the process for evaluating pressure

equipment?

Firstly, operators must determine the type of pressure equipment

being considered, e.g. piping, and verify whether or not the

equipment in question is covered under the PED and is not on the

list of exclusions. They must then determine the state of the fluid

within the equipment and evaluate which category it comes under.

For piping, the key factor is to define the diameter, which

is the nominal size of the components comprising the piping

system expressed in millimetres, and evaluate the state, pressure

and temperature of the fluid carried within the piping, in order to

categorise the level of hazard associated with the operation and

ensure compliance with the requirements of the PED.

What do the upcoming changes to the PED

involve?

Essentially, the changes to the directive look to clarify and

streamline the regulations in bringing pressure equipment to the

market, particularly in an industry facing increasing competition

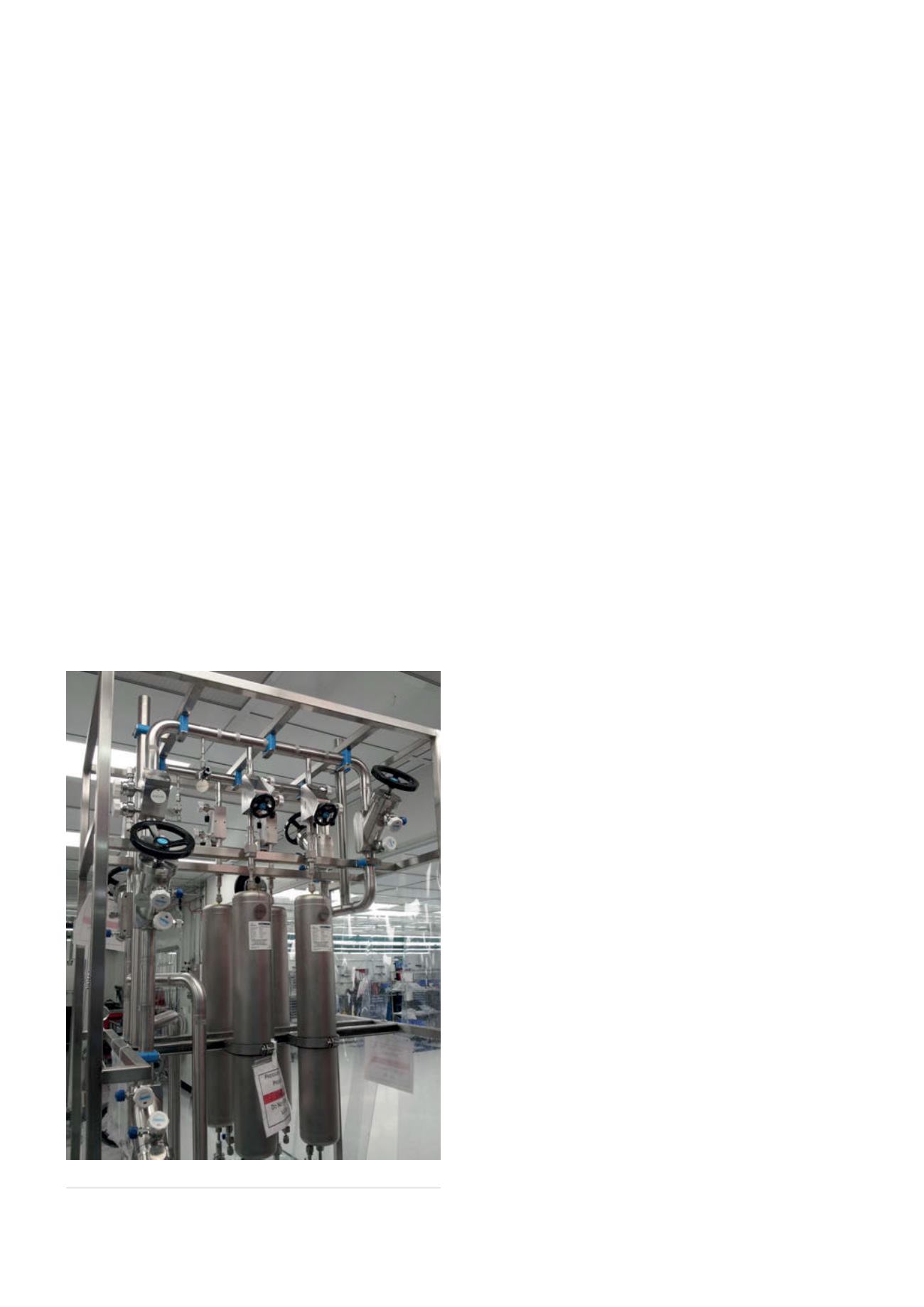

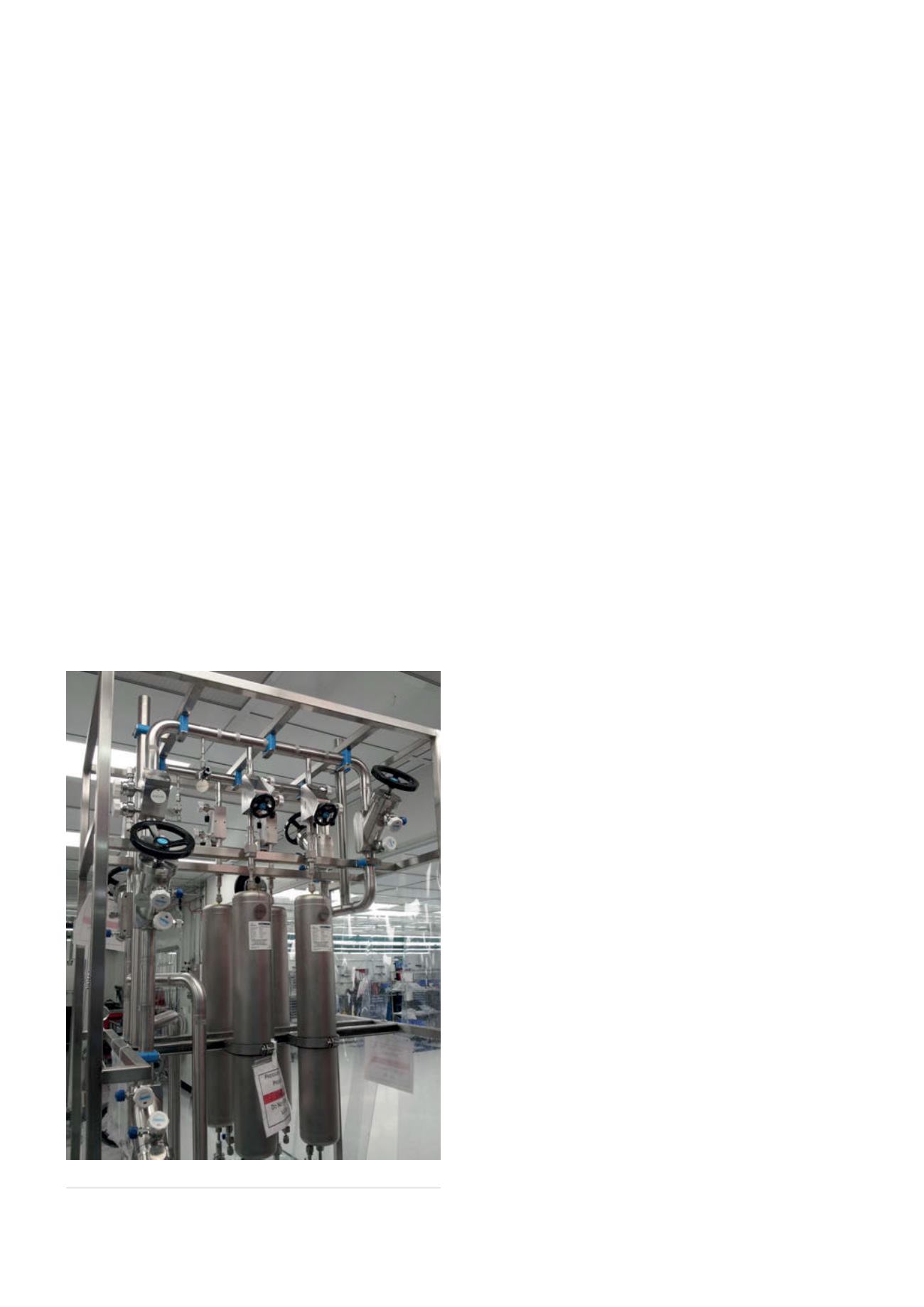

Figure 1.

A chiller skid that is a PED cat.II assembly.

68

World Pipelines

/

MARCH 2016