Weld purging techniques

Equipment has been developed over the past decade to make

purging much easier. Currently available systems are robust

and suitable for multi-use applications. They can be supplied

to cover the size range between 25 - 2400 mm dia.

The most effective devices are those based on

connected inflatable dams. These are programmed to

control gas flow and pressure during inflation and purging,

and once placed in position, require little more input

from an operator. The dams are fabricated using advanced

engineering polymers and are thus suitable for use with

oil and gas pipelines and processing plants where the

elimination of contamination is essential.

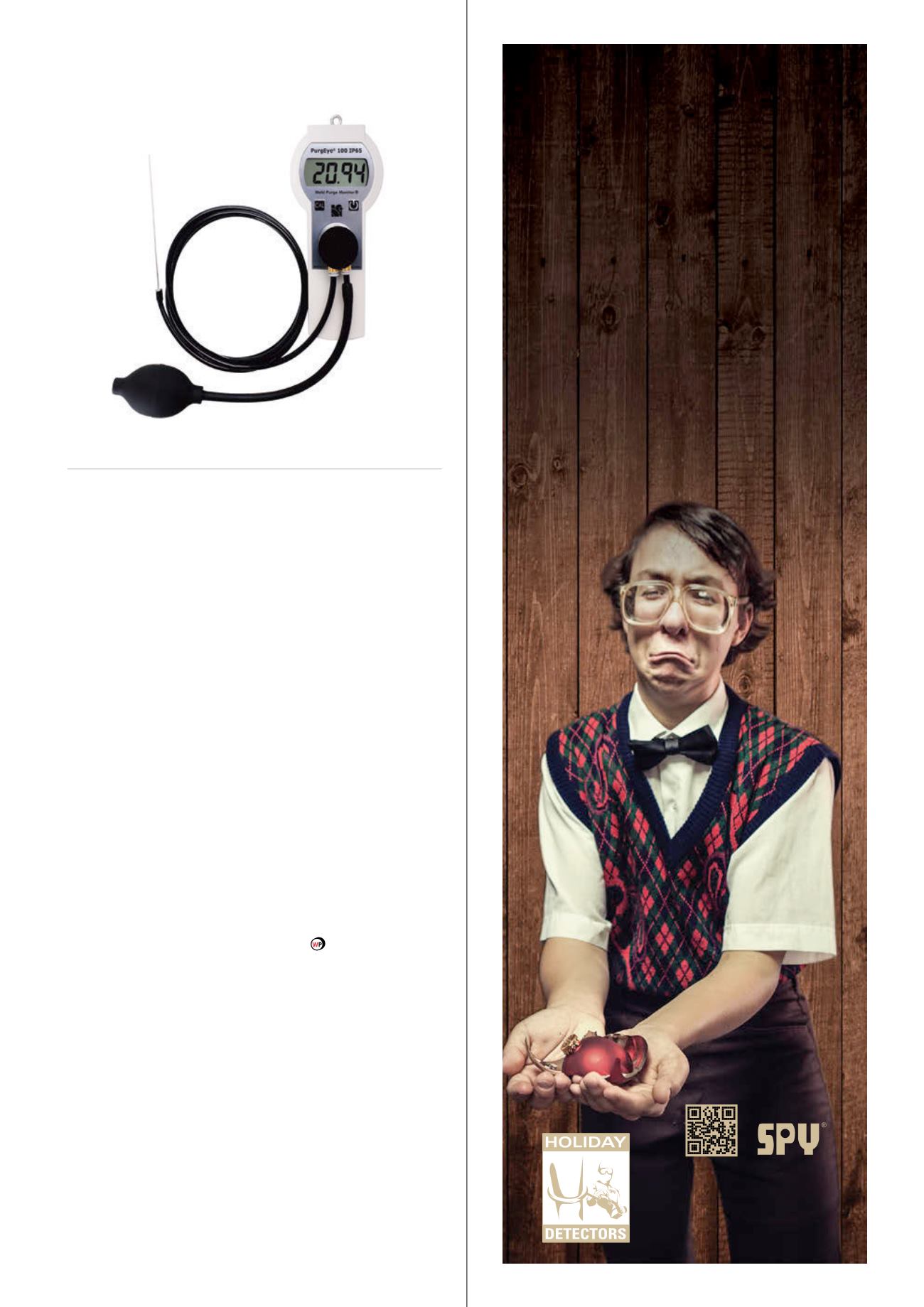

Purge gas oxygen content can be controlled by using an

oxygen monitor. These instruments not only measure oxygen

levels, but will inhibit welding if the level is above that set by

the operator. Recording and analysing software consequently

provides information for quality control purposes.

Conclusion

Even very low oxygen concentrations in weld gases can give

rise to discolouration and corrosion. Controlling oxygen level

in purge gas can be effected simply and efficiently using

contemporary integrated purge systems.

References

1.

EASTWOOD et al. 1993, welding stainless steel to meet hygienic requirements,

document 9, European Hygienic Engineering Design Group (EHEDG).

2.

TITZ, Jörg-Thomas, ‘Microbiologically influenced corrosion of stainless steel’, 2

nd

symposium on orbital welding in high purity industries, La Baule, France.

3.

‘Effects of purge gas purity and Chelan passivation on the corrosion resistance

of orbitally welded 316L stainless steel tubing’,

Pharmaceutical Engineering

, Vol

17, No 1 & 2, 1997.

4.

‘Considerations for Orbital Welding of Corrosion Resistant Materials to the

ASME Bioprocessing Equipment Standard’, Dr B. K. Henon, Arc Machines, Inc.,

Stainless Steel America Conference, 2008.

5.

AMMANN, Thomas, ‘Purging while welding’, BOC Australia, document 2010.

6.

NETTEN, G., ‘Necessity of removal of heat tints on stainless steel to avoid or

minimise corrosion’,

Vecon Netherlands Technical Bulletin

, July 2005.

7.

TABAN et al., ‘Effect of the purging gas on properties of 304H GTA welds’,

Welding Journal

, April 2014, Vol 93.

Figure 4.

Weld Purging Monitor

®

that can read from

atmospheric oxygen levels down to 10 ppm.

Since 1953

R

uining

H

olidays

Even the smallest bare metal exposure or

“holiday”

in nonconductive coating on a

pipeline or inside a vessel will

GROW

to

cause

BIG

corrosion problems down the road.

Since 1953,

Pipeline Inspection Company

has been ruining holidays before they ruin

the integrity of your coatings with fast and

innovative SPY

®

holiday detection equipment.

Visit our website to see our full line!

Pipeline Inspection Company

Phone : (713) 681-5837

Email :