oil and gas pipelines. Now, they’re also being used on some

utility installations.

“Just here in the past year we started using reclaimers

with our smaller rigs in certain conditions,” says Jim

Watland, Operations Manager for Dakota Utility

Contractors, which is based in Texas and performs utility

and pipeline HDD installations. “That helps us reuse the

water and reuse the chemicals.”

Second, contractors are sometimes using multiple

reclaimers on a single job, most often positioning one by

the drill and the other at the exit pit. This is most common

on larger diameter and lengthy bores when it’s difficult

to get from one side of the project to the other. Another

factor is the distance to the nearest dump site.

How reclaimers work

Drilling fluid helps create hole stability

and suspend and carry cuttings, making it a

critical component of a bore.

Reclaimers should not be confused

with mixing systems. A mixing system

supplies water mixed with drilling fluid

additives downhole to aid the drilling

process and maintain the integrity of the

opened hole. A reclaimer has an onboard

mixing system, but its primary purpose is

to recycle the used drilling fluid in order

to reuse that fluid. A reclaimer is made up

of hydro-cyclones, shakers and screens —

collectively referred to as solids control

equipment — that separate solids out of

the fluid and recirculate reusable fluid,

consisting of bentonite, water and other

additives, back into the active fluid system.

Large reclaimers are typically defined

as units that deliver fluid to a drilling rig

at a flow of 400 gal./min. (1514.1 l/min.)

or greater. They have three tanks that function in each

of the three stages of the reclamation process: scalping,

desanding and desilting. Fluid is transferred to the

different stages by centrifugal pumps.

Smaller reclaimers, with cleaning capacities of

350 gal./min. (1324.9 l/min.) or less, sometimes have two

tanks and skip the desanding stage by transferring fluid

directly to the desilting stage.

The first stage is the scalping pass, which is achieved

by the primary shakers. Scalping shakers receive 100% of

the flow that is pumped into the system from the return

pit. Scalpers are not meant to remove all the solids from

the mud, just enough so the downstream equipment can

work to its utmost efficiency.

The second stage, desanding, and the third, desilting,

are accomplished by feeding the scalped fluid into

polyurethane hydro-cyclones (or more simply put, ‘cones’)

at a predetermined pressure. Once the fluid enters the

cones, the fluid starts spinning on the inside wall. As this

fluid spins, heavier solids move toward the outside wall

and the lighter solids and fluid occupy the middle. The

heavier solids feed to the bottom of the cone where they

are then deposited on a shaker for further drying and for

the extraction of free liquid where possible. Finally, solids

are sent toward the end shakers and sent to a pit or roll-

off box for disposal.

As a rule of thumb, process rates for the cones should

be double that of the incoming fluid. This process allows

the cones to have another chance at extracting any

stubborn solids and also dilutes the solids’ loading ratio so

the cones can work more efficiently. It is only at this point

that the drilling fluid is ready to be received back into the

drilling process. A pump will send the cleaned fluid to a

Figure 2.

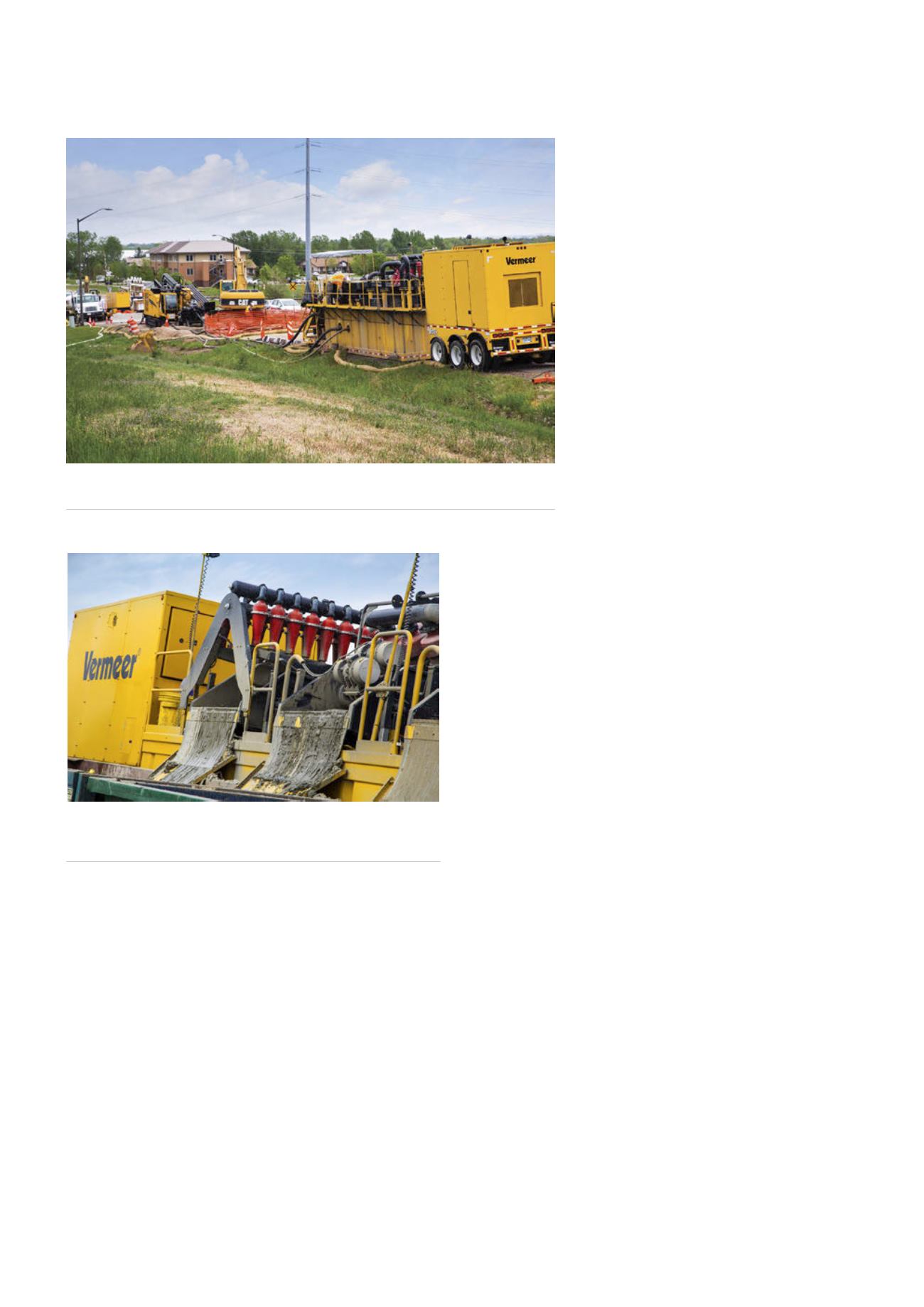

The growing use of reclaimers is worldwide trend. In fact, drilling fluid

regulations are more strict in Europe than in North America.

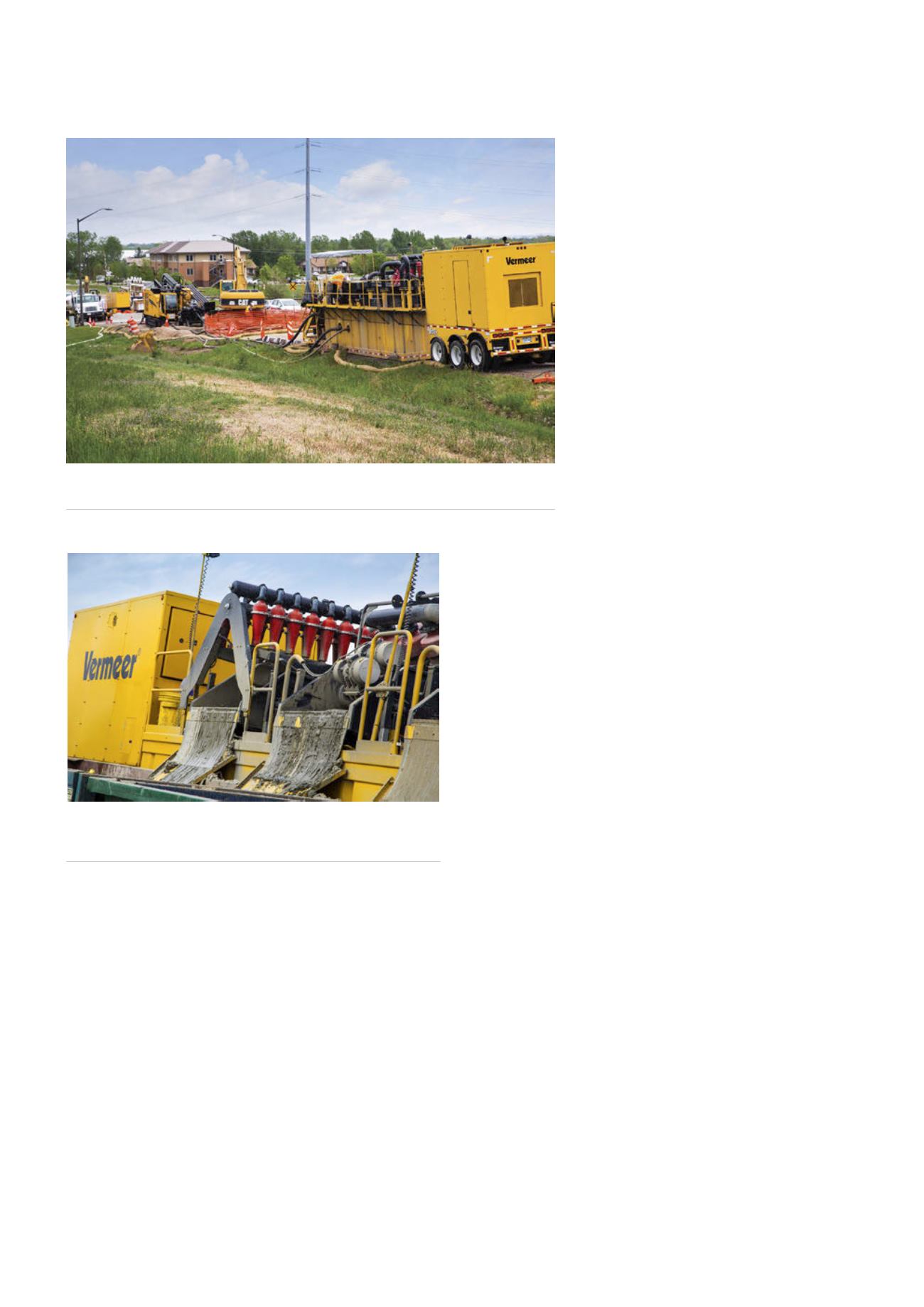

Figure 3.

A series of shakers, cones and screens on a reclaimer

filter out solids from fluid, with the cleaned drilling fluid able

to be used again.

82

World Pipelines

/

MARCH 2016