high-pressure pump for another trip down the bore path

to extract cuttings and carry them to the surface.

Reclaimers changing HDD

The growing adoption of reclaimers is changing the HDD

industry.

“I’d say the increase in mud recycling is one of the

biggest recent developments in the industry,” Heinen says.

This evolution has been spurred by the rising costs

and number of regulations for drilling fluid management.

Requirements vary not just state to state or city to city,

but sometimes job to job because project owners have

different rules.

Also, Heinen says the number of dumpsites is

decreasing, and he’s aware of contractors who have

left jobs because the disposal process became too

burdensome. The issue has grown to the extent that it

should be a central consideration when bidding on a job.

Watland, of Dakota Utility Contractors, says thinking

through drilling fluid needs and disposal is a major part

of his job — and four managers who work under him also

spend time on this.

“It’s very, very hard today to figure out what you’re

going to do with your mud,” he says. “We have to figure

out where we’re going to go get water, how to dispose of

our mud and whether we should use reclaimers so that we

can clean our mud and reuse the drilling fluid so that we

don’t have so much expense.”

On a job in Arkansas in early 2016, a Dakota Utility

HDD crew was required to haul drilling fluid to a class I

landfill accepting hazardous waste. The nearest facility

was a two hour drive one way from the jobsite, four

hours roundtrip. That’s four hours in labour costs for the

drivers, transportation costs and a disposal fee of up to

US$1000 per load.

Frank Canon, one of the godfathers of drilling

fluid use in the HDD industry, also talks up the

importance of reclaimers. Canon, who retired last

year as a Senior Account Representative at Baroid

Industrial Drilling Products and remains active in

the industry as a consultant, says reclaimers can

help reduce the costs of drilling fluid disposal.

“The difference in cost between disposing of

solids filtered out by a reclaimer versus disposing

of the whole fluid can be tremendous,” he says.

The adoption of reclaimers is a trend that is

occurring worldwide, according to Canon. For

example, drilling fluid regulations are even more

stringent in Europe than in North America.

Picking a reclaimer

Although reclaimers are becoming more common

on HDD jobsites, when to use one is still most

often determined on a project by project basis.

Contractors should take into account the

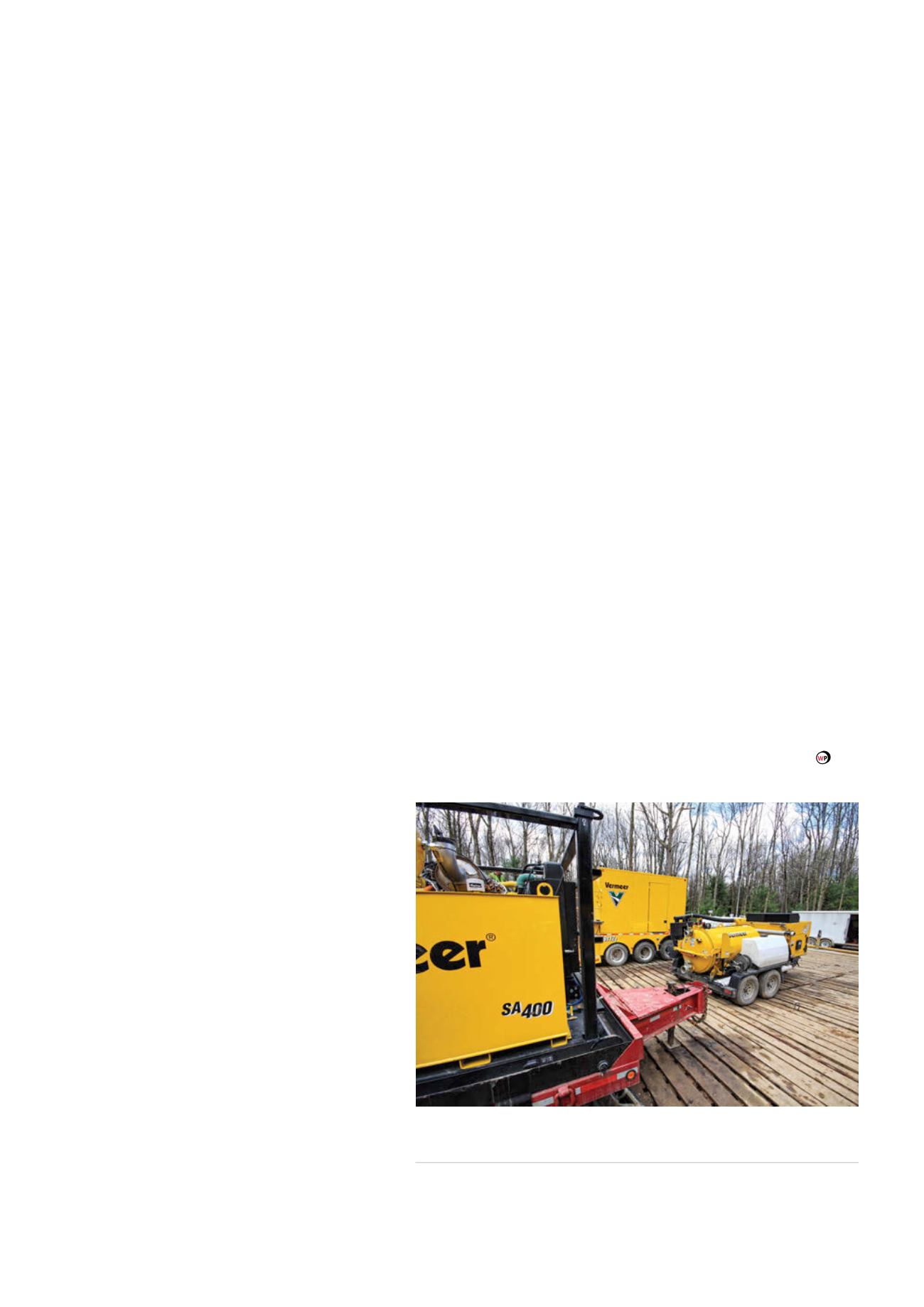

Figure 4.

Among the features to consider when shopping for a reclaimer,

look for a machine with a pump and cleaning system designed to work at

the same flowrate, which helps to maximise productivity.

estimated cost of fluid disposal, hole diameter, bore

length, ground conditions and water source.

As a general rule, a project that requires 7500 gal.

(28 390.6 l) or more of fluid per day is one where a

reclaimer should be considered.

When it comes to picking a reclaimer, Heinen says a

contractor should work with a local dealer to find the

right fit. Some bits of advice from him include:

)

)

Make sure screens for the reclaimer are readily

available. Some manufacturers make custom-sized

screens only, forcing reclaimer owners to buy the

part from them.

)

)

Look for a reclaimer with a high-pressure pump

whose capacity is equal to the cleaner capacity,

which allows for higher efficiency.

)

)

Also important is having the pumps match the

cones, which helps improve the efficiency. Some

manufacturers undersize pumps to lower the

purchase price of a reclaimer, but that could cost the

owner over the long-term because the mud won’t be

as clean.

)

)

Get a unit that effectively removes sand. Sand that

gets through the reclaimer process can harm the

pumps on a horizontal directional drill.

)

)

A reclaimer’s mixing and cleaning capacities should

be robust enough to meet a contractor’s needs.

Some units fall short in those categories.

“Drilling fluid disposal, its cost and the location

of dumpsites, are a growing headache for HDD

contractors,” Heinen says. “Fluid recycling, through the

use of a reclaimer, has the potential to offer relief.”

MARCH 2016

/

World Pipelines

83