processing plants, making the presence of systems for the

safe and effective control of pressure absolutely vital.

Failure to install and effectively maintain pressure relief

systems can have disastrous ramifications. Overpressure

in a pipeline can result in terminal – and therefore very

expensive – damage to the pipeline, with the very real

likelihood of an explosive release at a location and a

time that would be impossible to predict. When it is

remembered that this explosive release may be that

of a poisonous gas – H

2

S or otherwise – it is clear that

allowing any possibility for this type of event cannot be

countenanced.

For example, research has shown that even gas

concentrations below 5 - 10 ppm can have immediate and

significant effects on the human body, while it has been

demonstrated that continuous exposure to H

2

S levels far

below 1 ppm, can result in serious, long-term diseases

among these groups.

The alternative to an explosive release is that

unchecked pressure can travel further down the pipeline,

causing untold damage to process and equipment as

it moves. A pressure surge that reaches a compressor

unchecked can cause significant damage, resulting in an

immediate and very costly loss of production, to say

nothing of the extremely high replacement costs for the

compressor and other ancillary equipment.

Traditional methods of pressure relief

Over the years, the systems commonly chosen for this

function have been pressure relief valves. These valves

open up an alternative outlet for fluids or gases in a system

once a pre-set pressure is exceeded to avoid further

pressure build-up.

Typically, relief systems either vent gas into the

atmosphere, or to a venting stack for flaring. Venting to the

atmosphere is far from friendly to the environment and is

a potentially major issue where the discharge of gas with a

high concentration of H

2

S is concerned. This represents a

significant health hazard for workers and anyone else in the

vicinity.

The alternative solution – the use of flaring – presents

its own problems. It goes without saying that the presence

of naked flames represents a potentially significant hazard

in itself. The flaring process can produce a range of

combustion gases, which can each cause harm to anyone

nearby depending on the contents of the original gas.

This combustion also generates greenhouse gases and

is a significant contributor to national emission levels.

Meanwhile, overpressure gas, which is flared to reduce

pressure, is simply being wasted.

Their simplicity, relatively low cost, and lack of

environmental restrictions made them popular for many

years in spite of their usually large footprint.

The search for safer alternatives

However, in light of increased environmental concerns

and the need for greater onsite safety in line with the

requirements of safety integrity level (SIL) 3, leading players

in the marketplace sought an alternative. This came in with

the development of the very first high-integrity pressure

protection systems (HIPPS) in Germany, a country even then

renowned for its commitment to operational safety. The

role of the HIPPS is to shut off the source of high pressure

before the design pressure of a system is exceeded;

negating the possibility of a loss of containment through

the rupture of a pipeline, as well as preventing damage

to system components through exposure to excessive

pressure.

Ideal for incorporation into new systems, HIPPS can also

be retrofitted into existing pipeline systems to optimise

safety and reduce the need for flaring.

HIPPS products form part of a broader family of

components known as high-integrity protection systems

(HIPS), which effectively include any device whose role is

to protect the downstream portion of any plant or process

system. HIPS can be introduced into any existing plant –

whether upstream, midstream or downstream – to help

ensure compliance with international or local safety or

environmental regulations.

The key difference between a relief system and a HIPPS

is that whereas the relief system is designed to remove any

excess inflow of fluids for safe disposal, the HIPPS stops

the inflow of excess fluids and retains them in the system.

This last point is key as it negates the possibility of the

release into the atmosphere of harmful gases, as well as the

dangers associated with flaring.

The very first systems were designed to close a pipeline

and consisted primarily of ball and butterfly valves,

representing an effective solution at a relatively low cost.

Development has continued at a rapid pace since then,

and modern systems are now much more sophisticated,

incorporating high-specification logic controllers,

solenoids, redundancy systems and parallel measuring

technology. These components enable fully remote

operations with premium reliability and ensure the highest

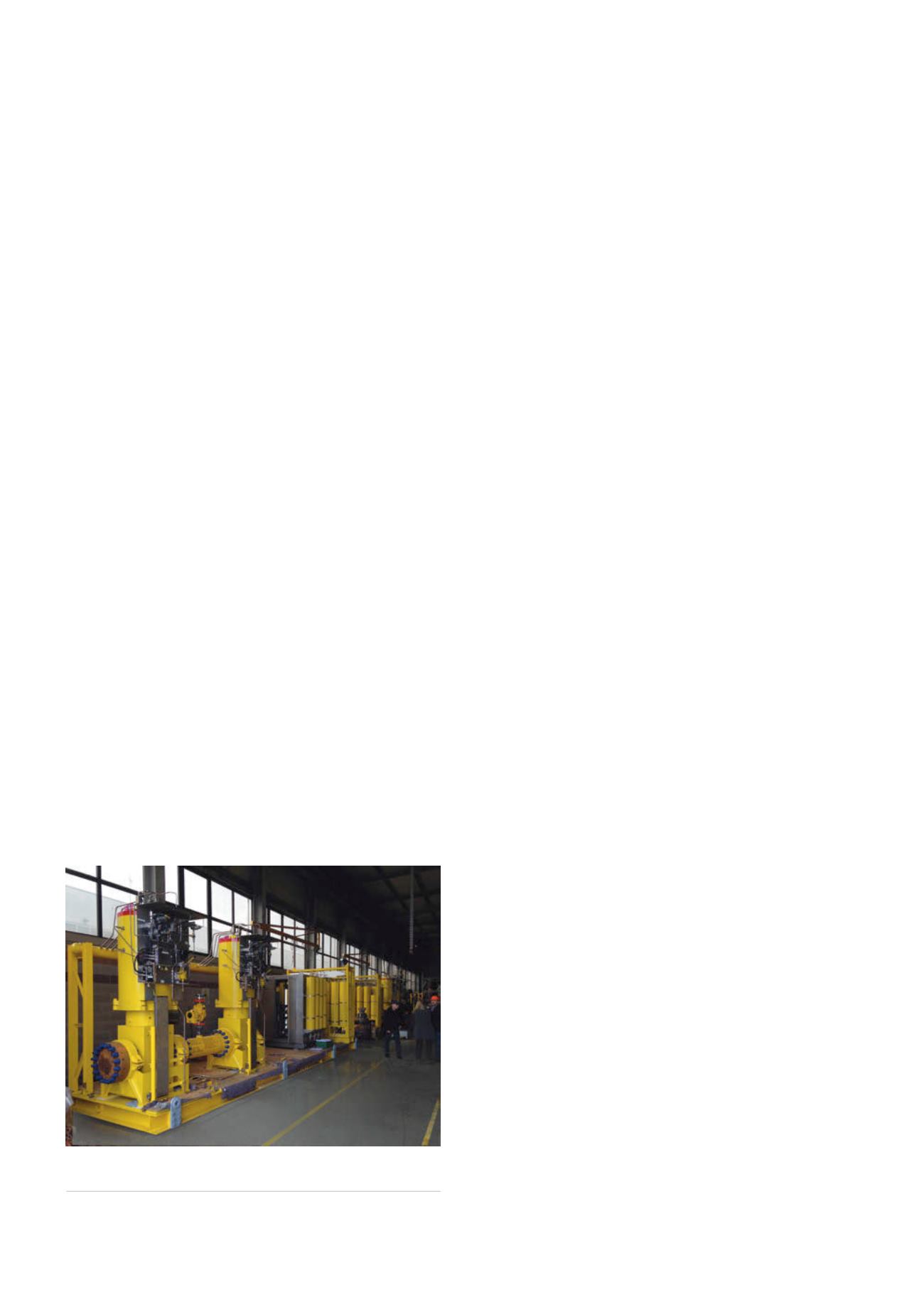

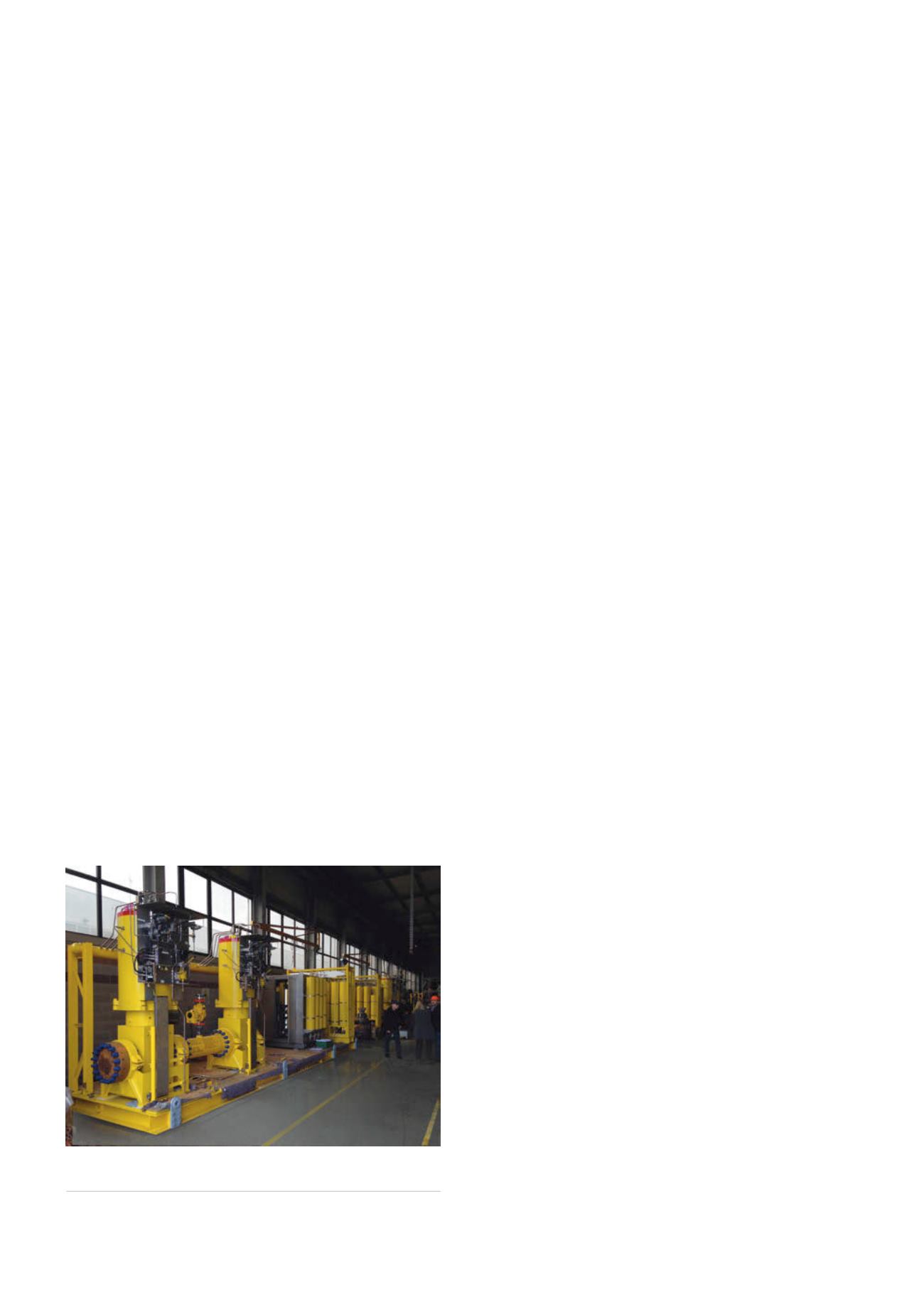

Figure 1.

HIPPS systems can be fitted into new systems or

retrofitted as required.

72

World Pipelines

/

MARCH 2016