Coatings

&

not possible. Properly preparing the surface according to the

coating manufacturer’s recommendations is an important

step in the rehabilitation process. Checking cleanliness and

roughness are important tests that should be performed on a

regular basis.

After the surface is properly prepared, the coating

should be applied as quickly as possible. This is especially

necessary when pipes being rehabilitated are located in damp

environments where surface oxidation can rapidly occur. If a

surface has been exposed to moisture for an extended period,

applied coatings run the risk of performing poorly. Therefore,

environmental conditions should be monitored regularly.

Using an automated system to perform these checks can

reduce the risk of failures.

The most common rehab coatings are two-part epoxy

coatings. Normally these are applied at specific volumetric

ratios, for instance 3:1. This ratio is very important to ensure

that the coating is cured correctly. Aegion Coating Services

uses traditional plural component rigs, but they also have

electronically-monitored rigs that can verify the ratio in real

time. These advanced systems log all of the appropriate

parameters (pressures, flows and temperatures) and shut down

the operation if the ratio is out of the allowable range.

Following the application of the coating and a suitable

cure time, non-destructive testing is performed. The cure

of the coating is verified with a hardness test. Improperly

cured coatings will be too soft and should be stripped and

recoated. Dry film thickness is also checked in multiple areas.

The previous steps can be repeated for each layer of coating

if more thickness is required. Properly trained applicators

are key to making sure that the right thickness is applied the

first time. Finally, the coating is checked for holidays, which

are then repaired according to the coating manufacturer’s

recommendations.

Biggest challenge to the pipeline

coatings industry in 2016

As the oil and gas services industry reels from

low oil prices and capital spending cuts at

many exploration and production firms, the

pipeline coatings industry will experience a

similar ‘recession’ as pipeline projects originally

forecasted for execution in 2016 continue

to experience delays while oil prices remain

stubbornly low.

Despite the gloom, the long-term

fundamentals for the pipeline industry as a

whole remain positive. The IEA has forecasted

net positive growth in demand for energy

in the coming years, despite the current

depressed prices. This demand will lead to

increased production while consumption

markets continue to grow, stimulating a

need for pipeline infrastructure to transport

hydrocarbons. As exploration trends towards

new frontier environments, there will be

demands for stronger and more sophisticated

coating solutions for line pipe, field joints and subsea

equipment.

This confluence results in a need for increased research

and development in the pipeline coatings industry. However,

in the face of weak oil prices, obtaining such funding might

be tricky if industry players do not adopt the long view.

Increasingly, companies such as Aegion are investing in

offshore and onshore pipe coatings technology. Aegion

continues to execute deepwater insulation coating projects

for oil and gas clients and has an extensive backlog at its new

BWI integrated pipe coating plant. Our mobile coatings unit –

Aegion Coating Services – has made considerable investments

into planning for the growth of the deepwater coatings

market while pressing forward with field coating projects in

countries such as Azerbaijan, Oman, Chile and all throughout

North America.

Pipeline coating specialists – such as Aegion, with

its corrosion protection platform comprising renowned

energy asset protection brands such as Corrpro, The Bayou

Companies and United Pipeline Systems – will enter 2016

leveraging its execution experience on high-profile, technically-

challenging pipeline projects while reinvesting in research and

development of novelty anti-corrosion and thermal insulation

coating materials and safer, more precise and more efficient

automated robotic coating technology for field applications.

Additionally, we have combined our field coating technology

businesses CRTS, Inc. and Commercial Coating Services

International, LLC into one group – Aegion Coating Services.

This allows us to now mobilise services for both internal and

external field joint coating worldwide.

References

1.

-

from-2016-onwards/

2.

aspx?id=283f80c3-1ea5-e111-ac69-0050569a007e

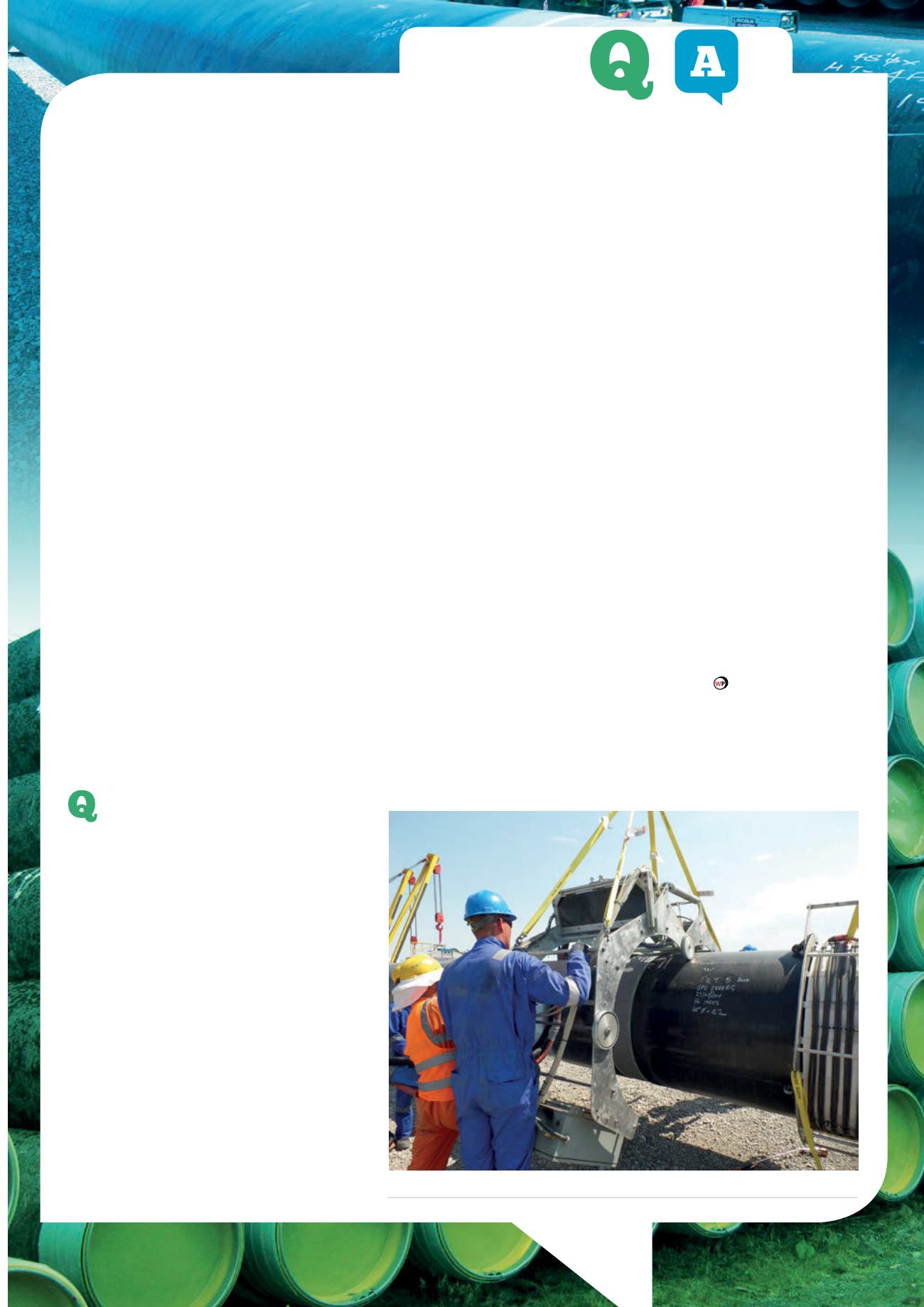

Figure 2.

Automated liquid coating ring.

51