Coatings

&

These five technologies, which had already earned their

own reputation independently within the market, are Polyken

Tape Solutions, Powercrete Liquid Solutions, Stopaq Self

Healing Corrosion and Sealant Systems, Anodeflex Cathodic

Protection and Covalence Heat Shrinkable Products. In

addition, new brands – Blockr, EasyQote, Synergyq and

Sealtaq – are being introduced, which will make it possible

to fulfil the needs of many more (and new) markets for our

solutions and innovations.

It is precisely the complementary strength of our

specialisms that enables us to speed in with a specific,

tailor-made solution for any challenge, in any infrastructure,

anywhere in the world. Above or underwater, from salty

marshlands to complex operations in the Arctic, Seal For Life

Industries will prove our principle that ‘1 + 1 = 3’. By maintaining

an open line of contact between our specialist technologies,

Seal For Life can react fast and effectively, and suggest

custom-made approach for each particular project.

Specifications for pipe coating plants

For many years European countries have written

national pipeline coating specifications, e.g. Germany – DIN,

France – AFNOR, UK – BSI etc. There have also been many

company specifications, and in addition those produced by

consultancies for specific projects. Over the last few years,

there has been a definitive move to write European – CEN

and ‘World’ – ISO standards.

When the ‘Vienna Agreement’ is applied this sometimes

allows that the same document be used as a CEN and ISO

standard, hence obviating the requirement for two similar

documents. These CEN and ISO standards give every

company, large or small, the opportunity to utilise modern

pipeline coating standards.

However, these CEN and ISO standards dictate minimum

pipeline coating criteria, and can be lower in technical

requirements than a corresponding company standard, and

sometimes a national standard.

Coatings repair and rehabilitation:

inspection, repair methods, testing

The application of CP can also be a negative influence on the

quality of the external coating. Applying too much CP current

onto the pipe may lead to overprotection of the steel. This

results in the production of hydrogen gas at the steel surface.

With thin layer external coatings, such as liquid epoxies and

FBE, the production of hydrogen gas will result in blistering of

the coating and in time it will break down. Disbondment of

the external coating may occur around a coating defect.

The extent of disbondment is dependent on the coating

type, the adhesive properties of the primer and the resistance

of the total system to disbondment. In the space between the

steel surface and the coating, water and other contaminants

containing positive ions may accumulate. In the disbonded area,

sufficient current from the CP system cannot be applied. As a

consequence, external corrosion is likely to occur. This process

is referred to as ‘cathodic shielding’ at the disbonded areas.

SFL advices to start the selection and recommendation of

coating based on the application conditions such as ambient

temperature, access and expected extended service life.

Coating selection based on Sa 2.5 blasted is not necessary,

as newer technologies and combination of technologies

are available to rehabilitate live ‘cold’ gas pipelines without

blasting.

Which convention, conference, standards

and guidance are of most relevance to

the pipeline coatings industry?

Before one can determine what coating system to

recommend, you must establish what goal or goals are

to be achieved. There are generally four main reasons for

application of a coating system:

)

Protection of the capital investment.

)

Beautification/aesthetics.

)

Product purity.

)

Environmental protection.

Protection of the equipment is usually the first and

most obvious goal. Sometimes a particular colour and gloss

is required. In the case of tank linings, the need to provide

a surface that will maintain product purity is essential.

Increasingly, containment areas must be designed to prevent

hazardous spills from reaching the environment. One

must also determine what is an acceptable service life for

maintenance or replacement.

How does this affect coating system selection? On an

offshore platform in the North Atlantic, there may only be 10

days a year that are suitable for coating maintenance. Perhaps

the lifecycle of the facility is limited. NACE, IPLOCA, Ceocor,

Cefracor, Eurocorr, Itanks, ISO 21809-3 and 11 are relevant to

the industry as a knowledge source.

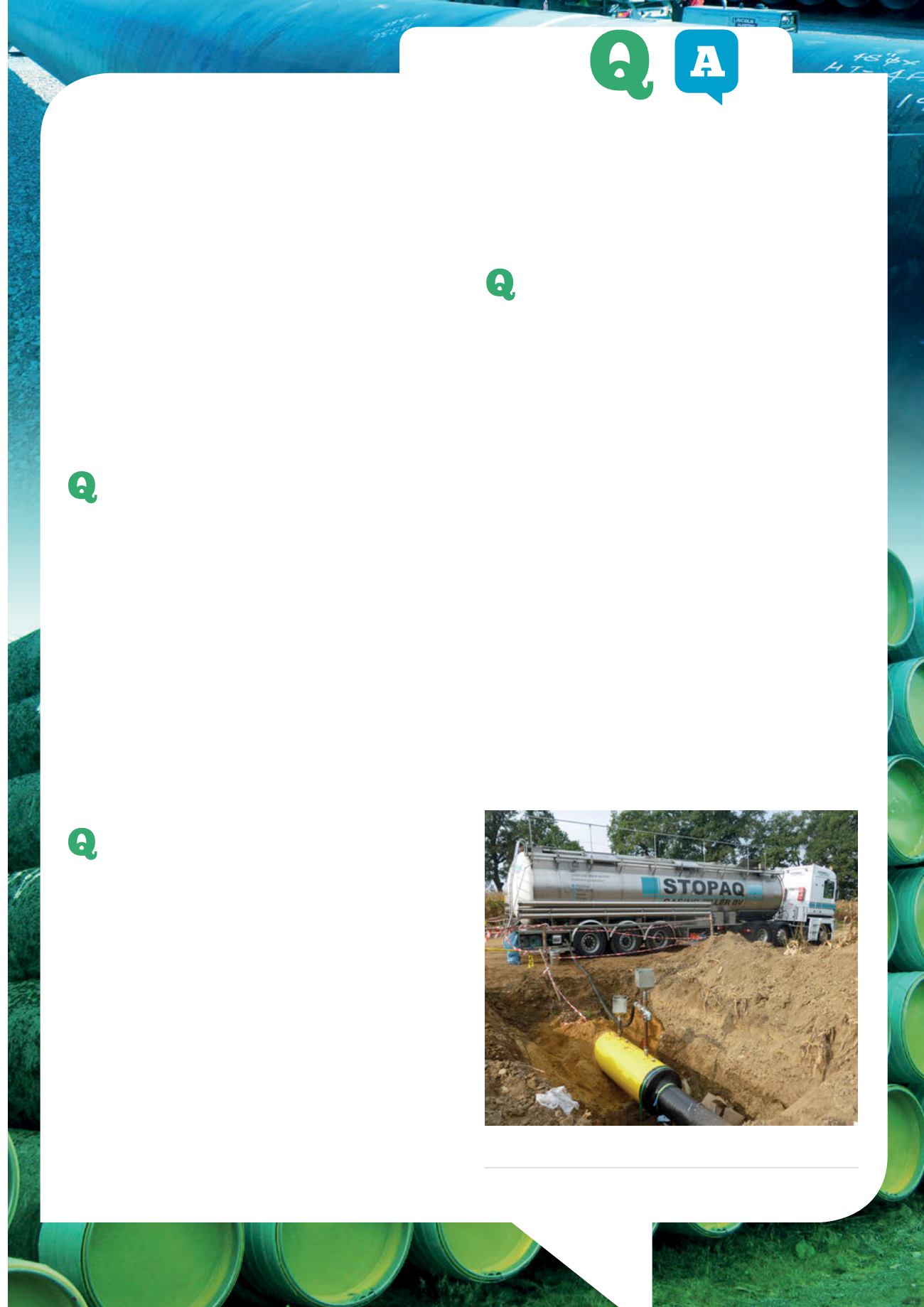

Figure 2.

Nederlandse Gasunie NV, 48 in. field joint coating of

high impact shield applied in 8 min. per joint.

47