constructed to the DNV OS-F101, which is currently used for 65%

of new subsea pipelines around the world. For onshore pipelines

or subsea pipelines designed to other codes – especially vintage

pipelines – welded sleeve repairs may not be possible, as a too

high HAZ hardness may be obtained. In such cases, alternative

repair methods using a combination of bolted full encirclement

split sleeves injected with epoxy grouting may be an alternative.

Welding considerations

While there are concerns when welding onto an in-service

pipeline, it can be relatively straightforward provided that well-

established guidance is followed. The first of these concerns

is for ‘burn-through’ – or blowout as it is sometimes referred

– where the welding arc causes the wall of thin-wall pipe to be

penetrated. The second concern is for hydrogen cracking, since

welds made in-service tend to cool at an accelerated rate as the

result of the flowing contents ability to remove heat from the

pipe wall.

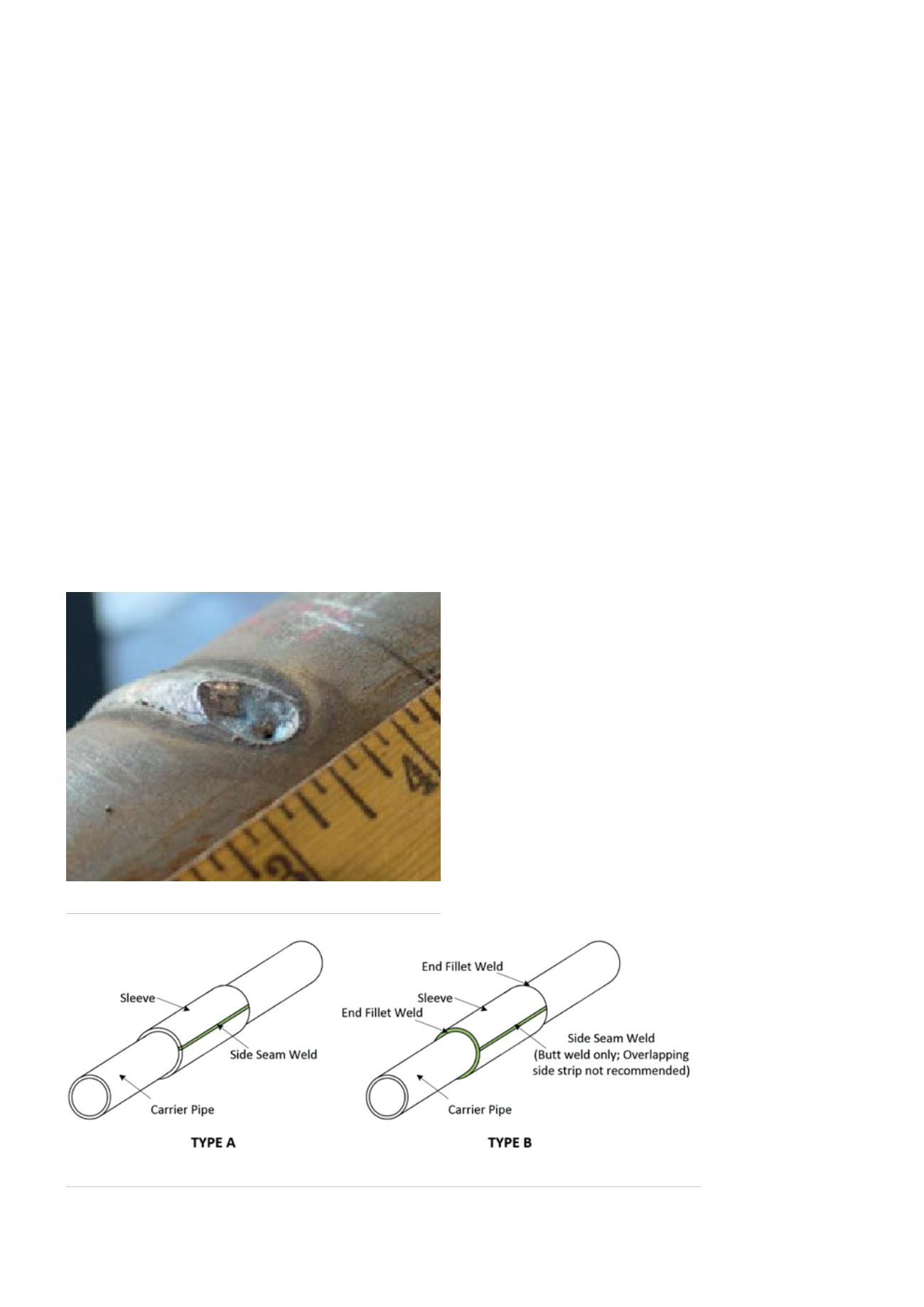

A burn-through will occur when welding onto a pressurised

pipe if the unmelted area beneath the weld pool has insufficient

strength to contain the internal pressure. A burn-through

typically results in a small pinhole in the bottom of what was

the weld pool (Figure 2). The risk of burn-through will increase

as the pipe wall thickness decreases and the weld penetration

increases.

The most useful tool for evaluating and preventing the risk

of burn-through is thermal modelling analysis using either the

Battelle model or the PRCI model. These computer models

predict inside surface temperatures, which must be kept below

982˚C (1800˚F), in order to minimise the risk, as a function of

the welding parameters (current, voltage, and travel speed),

geometric parameters (wall thickness, etc.) and the pipeline

operating conditions (contents, pressure, flowrate, etc.). The risk

of burn-through for a given application can then be evaluated

based on these parameters, which in turn help to determine

the limiting welding parameters for a given set of operating

conditions.

To prevent hydrogen cracking in welds made onto in-service

pipelines, the weld hydrogen level should be minimised by using

low-hydrogen electrodes or a low-hydrogen welding process.

As added assurance, welding procedures that minimise the

formation of crack-susceptible microstructures should be used.

The importance of controlling hydrogen levels for welds

made onto in-service pipelines is well established. The results of

recent work show that close control of hydrogen level allows

HAZ hardness in excess of 350 HV to be tolerated. Storage and

handling of low-hydrogen electrodes is an inexact science at

best, even though general guidelines for their use are available.

The hydrogen level of welds made using low-hydrogen

electrodes can vary widely depending on a range of factors.

Many of the potential problems associated with minimising

hydrogen levels for welds made onto in-service pipelines,

and therefore minimising the risk of hydrogen cracking,

can be addressed by using low-hydrogen electrodes with

supplementary designators that limit weld hydrogen levels. A

standard set of procedures can be qualified that cover a range of

conditions. Simple guidelines can then be developed so that the

simplest procedure can be selected for a specific application.

Available technologies and techniques

Welded sleeves

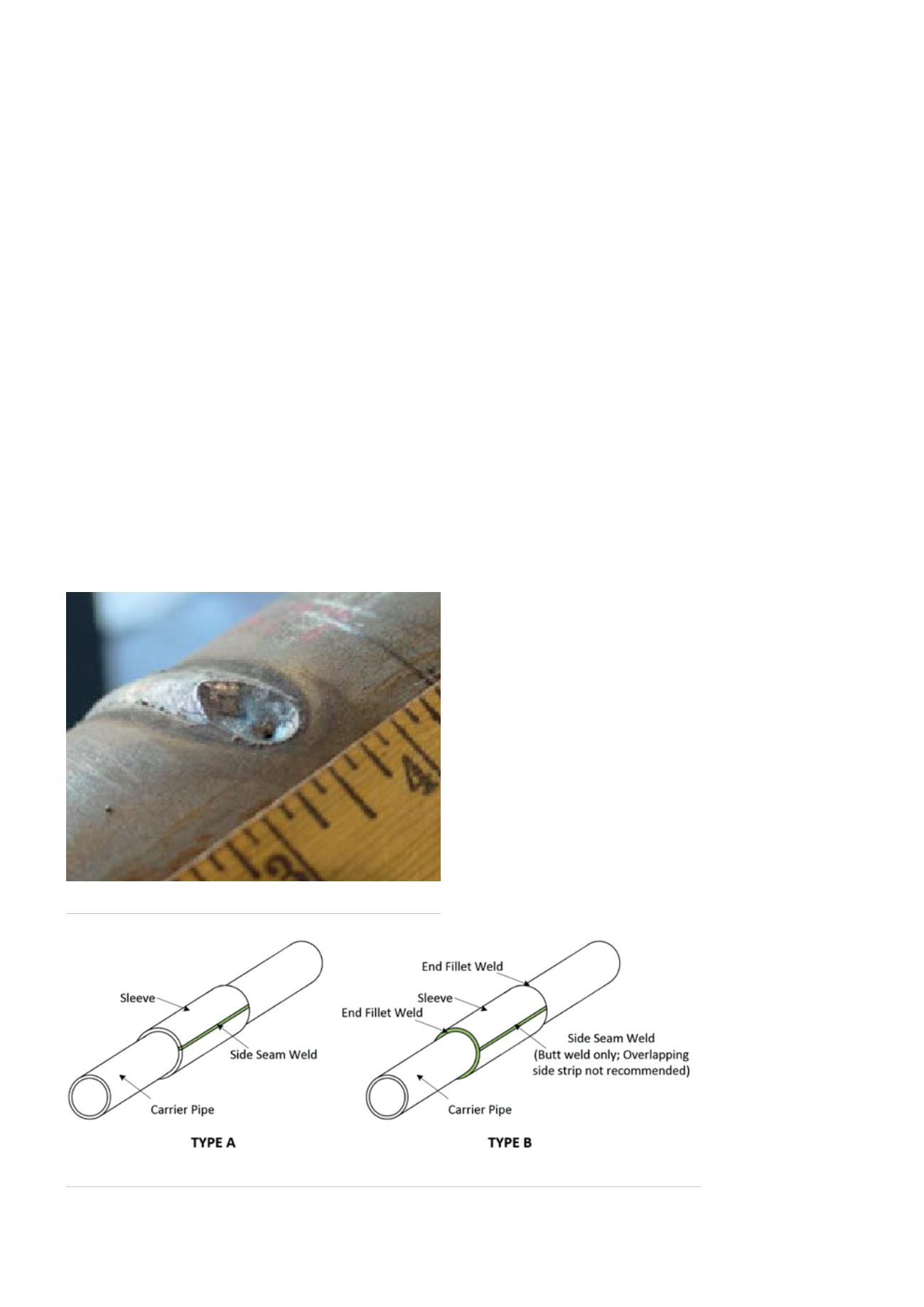

Early works by Battelle in the 1970s show that welded full

encirclement split sleeves can provide structural strengthening

and are capable of completely restoring the strength of the

damaged area. Type A sleeves are not welded to the pipe at

each end. However, sleeves need to be welded to contain

leaking defects and provide resistance to axial stress. So-called

Type B sleeves are usually welded using a special fillet welding

procedure, involving

weld buttering layers

before the fillet weld is

completed (Figure 3).

For leaking

pipelines and pipelines

with deep girth weld

flaws, DNV GL has

been involved in

developing welding

procedures for repairs

of live pipelines not

requiring shutdown.

Some of the repairs

have involved

Figure 2.

Typical burn-through on 0.125 in. (3.2 mm) thick pipe.

Figure 3.

Type A and Type B tight fitting full encirclement split sleeves.

38

World Pipelines

/

MARCH 2016