24 |

Oilfield Technology

June

2016

structure (Figure 3). Additionally, to meet the demands of more

main hole applications (typically below 8 ¾ in. diameter), many

of these designs are built using non-rotating diamond gouging

inserts that maximise wear resistance in long and challenging

intervals.

Casestudies

An operator in Western Canada was attempting to drill an

8 ¾ in. diameter interval, reaming a 95 ft long section in

a predominantly hard limestone formation of roughly 20

ksi compressive strength, followed by a 185 ft interval in a

predominantly dolomite formation of comparable strength.

Although short, this interval is very challenging mainly due

to the lithology of both formations – reaming is difficult with

conventional PDC bits, which frequently produce erratic torque

response, poor hole condition and excessive damage on the

gauge area of the bit in similar wells. Instead, 547 or 617 type

carbide insert rollercone bits are generally used, but usually

only ream at a 6 - 10 ft/hr average ROP and are subsequently

tripped out for a PDC bit in the lower section. Using a Generation

3 Pexus hybrid design (Figure 4) enabled the operator to ream

at approximately twice the ROP of a typical rollercone, saving

over 10 hours of operating time, as well as eliminating a trip by

drilling the entire section in a single run.

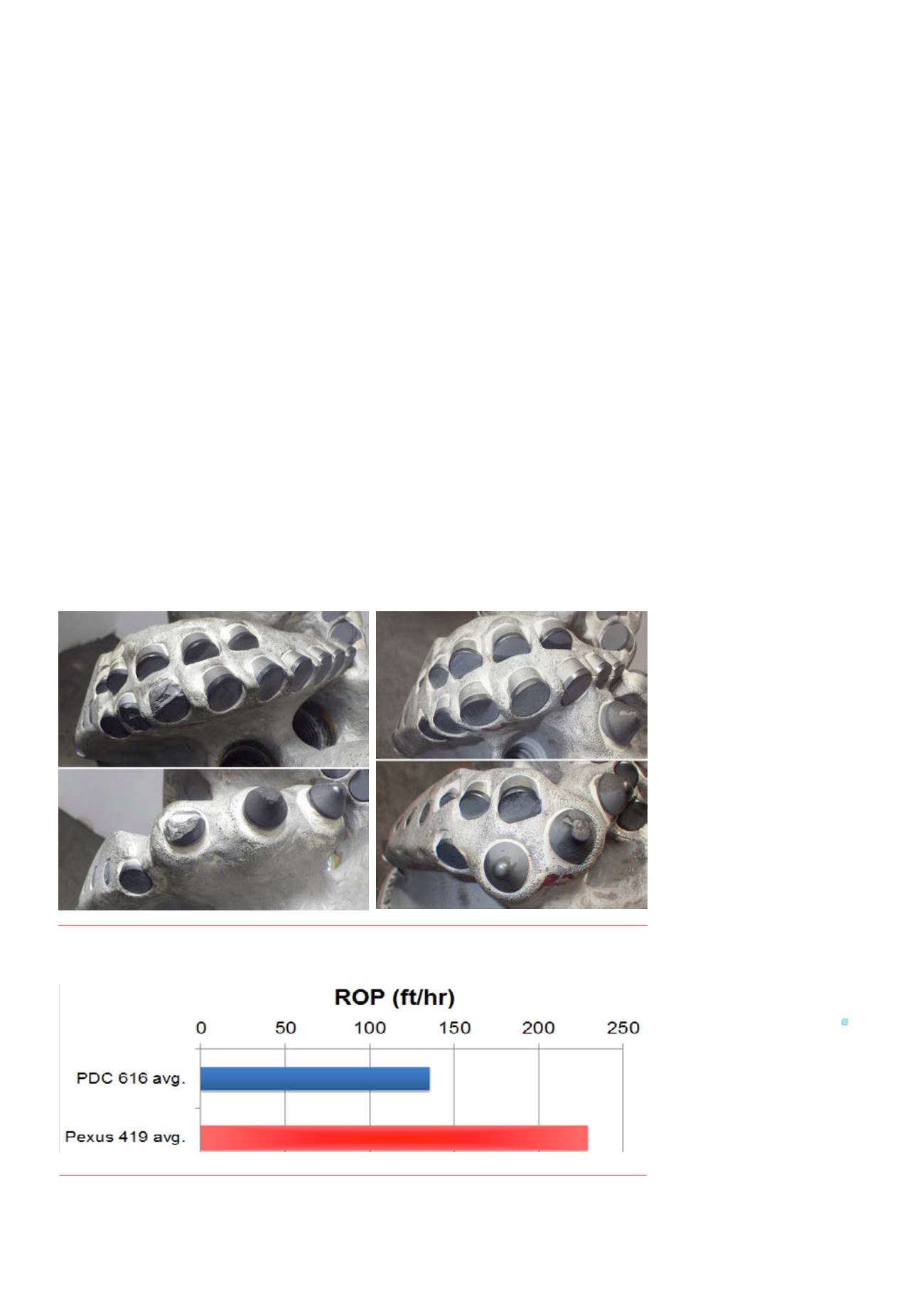

The dull condition (Figure 5) showed minimal component

damage in the cone and nose of the bit, largely due to the added

protection provided by the hybrid cutting structure. The reaming

portion of the run caused moderate to heavy breakage of the

gouging inserts and some PDC cutters on the outer shoulder and

gage; thus, it was concluded that future designs for main hole

applications could benefit from additional diamond volume and

protection in these areas.

Using the lessons learned from the 8 ¾ in. run, a Generation 3

Pexus design (Figure 4) was provided for a different operator in

Western Canada, drilling a 6 ¼ in. diameter, 1330 ft long build

interval through two formation types both consisting primarily of

siltstones with interbedded shales. In order maximise durability in

an application with high impact, abrasion and thermal demands,

the design featured twice as many blades of PDC cutters on the

outer shoulder and gauge compared to the 8 ¾ in. bit.

The operator commented that the bit provided very

consistent toolface control, even when run with extremely

high weight on bit (up to 40 000 lb) while sliding and when

transitioning from one formation type into the next. As

evidenced by the dull condition (Figure 5), the additional blades

of PDC cutters provided the outer shoulder durability necessary

to complete the interval with only minimal wear on the PDC

cutters and occasional chipping on the gouging inserts.

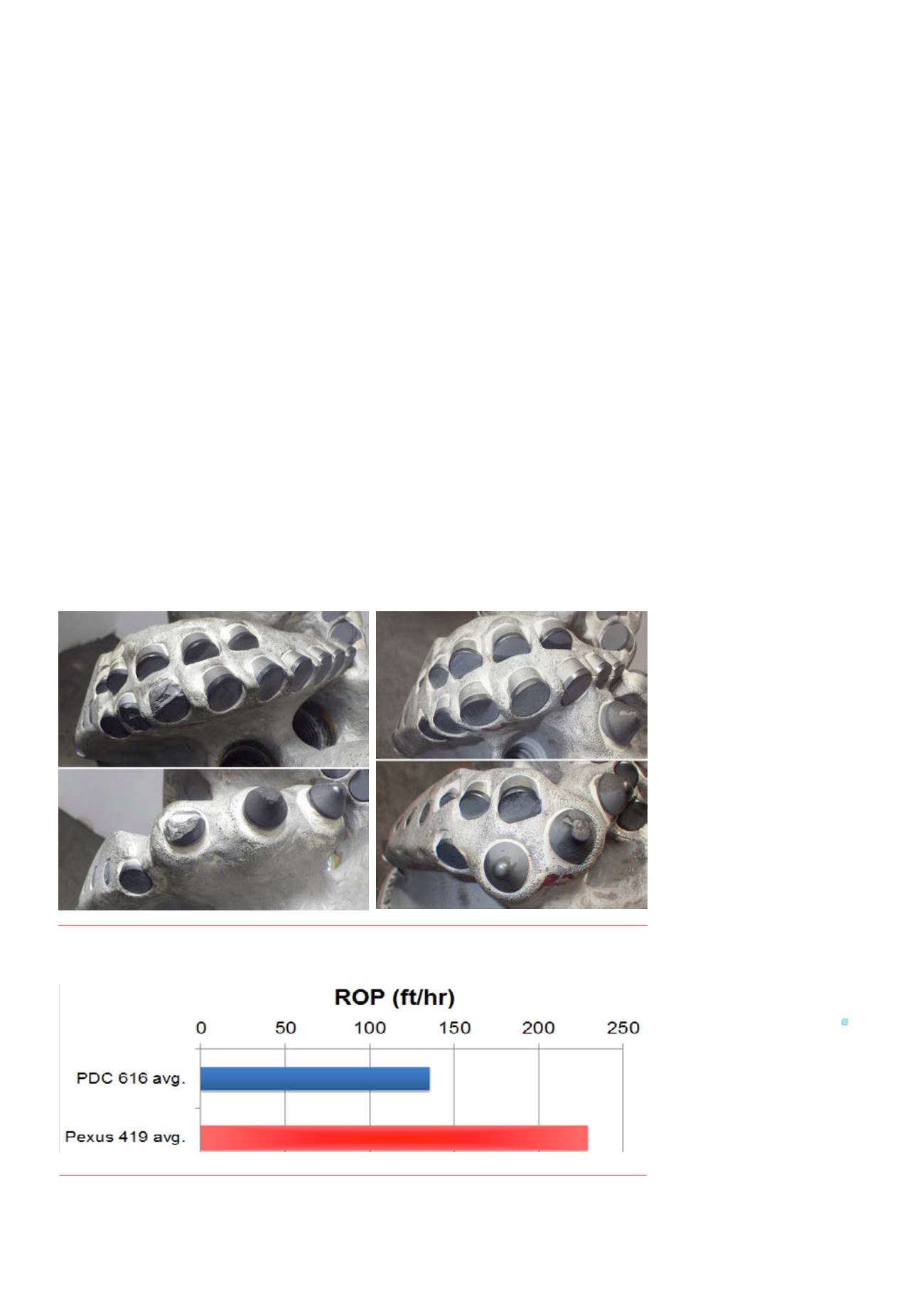

Generation 3 Pexus designs have also completed over

25 runs in surface applications since late 2015. In one field

area in Western Canada, 12

¼

in. hybrid bits are routinely

outperforming PDC bits in a formation of 4 - 10 ksi compressive

strength containing sand, shale, and some coarse grained

sediments. A search of 11 close offset wells shows that 419 type

Pexus hybrid bits achieved an average ROP increase of 69%

over 616 type PDC bits in run lengths between 1820 and 2020 ft

(Figure 6). The reduced blade

count consistently provides the

added aggressiveness needed

to significantly boost ROP,

without sacrificing toughness or

steerability.

Conclusion

Since the initial design concept,

Pexus hybrid drill bit technology

has taken significant strides

in its development. Three

generations of design iterations

have continuously strived for

improvement, consistently

achieving positive results

over hundreds of runs in a

wide variety of applications.

The hybrid gouging/shearing

cutting structure is engineered

to provide superior rock

fracturing capability, protection,

and directional control over

conventional drill bit designs.

References

1. Beaton, T., ‘A Hybrid Solution’, Oilfield

Technology, (November, 2014), pp.

45 - 49.

2. Beaton, T., ‘Getting Ahead with

Hybrids’, Oilfield Technology, (June,

2015), pp. 51 - 54.

3. Cookson, C., ‘New Drill Bits Boost

Efficiency, Safety’, The American

Oil & Gas Reporter, (April, 2016),

pp. 80 - 87.

Figure 6.

Average ROP comparison of 11 close offset 12

¼

in. diameter intervals.

Figure 5.

Dull condition of a 8¾ in. Pexus hybridbit after completinga challenging reamingand vertical section

(left). Dull condition of a 6¼ in. Pexus hybriddirectional bit after completinga challengingbuild section (right).