32 |

Oilfield Technology

June

2016

For example, experience in Canada determined that

increasing the blade height increased durability. Not only did

this increase the diamond volume of the blade, but it also

allowed more geometric space ‘inside’ the blade to work with.

HIP inserts were made bigger, which was advantageous as they

have superior diamond dispersion characteristics.

A second development for the bits used in Canada were

the design changes to reduce the likelihood of the bit getting

stuck. The overall length of the bit was reduced to decrease

the bit-to-bend length, the passive portion of the gauge was

undercut, and back ream cutters were added. The enhanced

performance was not achieved on the first bit run, but instead

was the result of ongoing design modifications all based on the

concept of custom designing the bit for a specific formation.

Canadianrunperformance

Fusion bits have been used in many Canadian wells with a

significant improvement in performance versus competitor bits

used in offset wells.

In the Lily Field in British Columbia, Canada, the Fusion bit

drilled faster and for a longer time than any other bit used on

the well pad, requiring only one bit to drill the section. Drilling

the 8 ½ in. vertical and build section typically requires two DI

bits to drill the full interval at an average of 2.5 m/hr (8.2 ft/hr).

By drilling 204 m (669 ft) at 3 m/h (9.8 ft/h), the Fusion DI bit

improved the average ROP by 20% and eliminated the cost of

another trip and a second bit.

The record setting performance is mirrored in other Canadian

applications that have also seen improved durability and ROP

using the application specific bit design.

In the Graham Field, the first run of a Varel VF1213 171 mm

(6 ¾) DI bit drilled above average footage at the fastest ROP

compared to offset DI runs drilled by two different competitor

bits in four separate runs. The Varel design made 84 m in

29.75 hours at 2.82 m/h compared to the offset average of

78.25 m drilled in 39.46 hours at 2.03 m/h. The Varel F1213 drilled

29% faster than the competitor average.

The Graham Field illustrates the type of formations where

the DI bits are used. Typically tripped in at the bottom end of

the Charlie lake formation and pulled just before the Montney,

the bits encounter an unconfined compressive strength (UCCS)

of 30 to 45 kPSI through this section. The lithology is primarily

abrasive sand, limestone and silt, making this an ideal candidate

for DI bits as PDCs dull off rapidly and roller cone bits are very

slow (< 1m/hr).

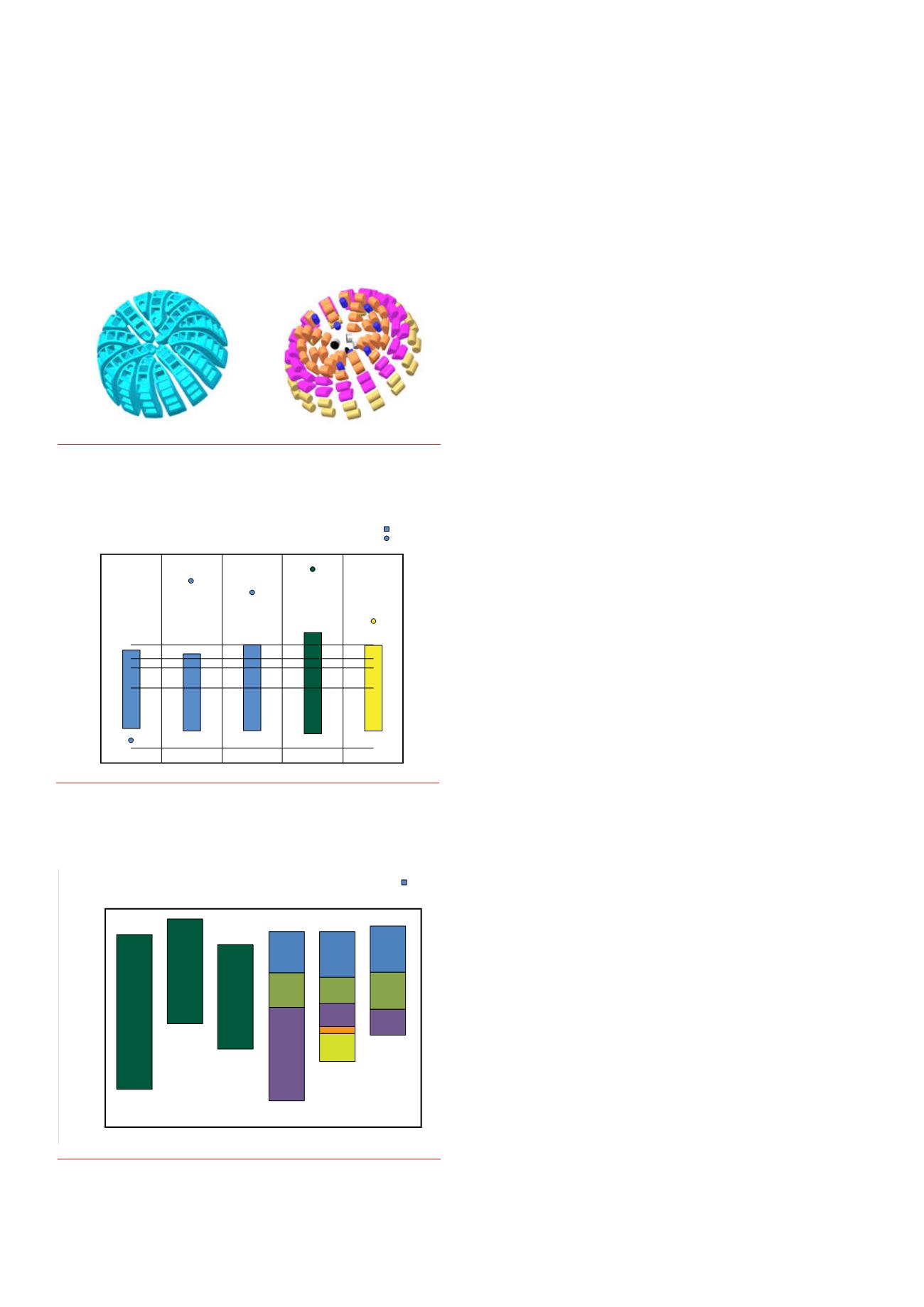

In the Town Field, a 216 mm F1616G2U Fusion bit drilled

194 m in 55.25 hours at 3.51 m/h compared to the offset

average of three offset bits of 153.6 m in 46.25 hours at 3.33 m/h

(Figure 1).

An Altares Field application used a 171 mm F1213 Fusion

bit to drill 217 m in 77 hours at 2.82 m/hr, 93% further than

the average meterage (112 m) in the area. All runs utilised a

high-speed motor. The formation compressive strength in this

section can reach as high as 45 kPSI with extremely abrasive

sand making conventional drilling uneconomical. To give an

example of how challenging this section is to drill, a six blade

13 mm PDC bit was tested. It drilled 7 m at 3.11 m/hr before

being pulled for penetration rate. The Varel F1213 allowed

the customer to stay on bottom longer while achieving an

exceptional rate of penetration.

Omanrunperformance

In Oman’s West Khulud Field, an F1613G Fusion bit now holds the

top three records for an 8 ⅜ in. single-run diamond-impregnated

bit. The most recent run increased footage by 46% over the

second run and a 223% gain in average offset footage using other

bits (Figure 2).

The Fusion bit runs in one of the deepest gas fields in

the world were initiated to exit the casing shoe and drill as

deep as possible in a single run. The field’s lithology presents

a significant challenge with abrasive sand, shale, and silt

exhibiting unconfined compressive strengths in the range of

Figure 1.

Varel modifies HIP segment size, shape, andplacement to

ensure the best designpossible for any application.

Figure 2.

Varel’s 216mmF1616G2Udrilled 26%farther than the

average offset in Town Field, BritishColumbia.

Figure 3.

The F1613Gused in thisWest Khulud Field run saved the

operator two trips, two bit changes, and eight days fromthe planned

schedule.

Impreg

Impreg

Impreg

F1616G2U

Average

216 mm Impreg Runs - Town Field, British Columbia

1650

1700

1750

1800

Amrk

Artex

Halfway

Doig

Montney

1850

1900

1950

2000

2050

3.0

3.05

3.1

3.15

3.2

3.25

3.3

3.35

3.4

3.45

3.5

3.55

Drilled Interval

ROP

Measured Depth (m)

ROP (m/hr)

F1613G

F1613G

F1613G

Impregs

Impregs

Impregs

2.15 m/hr

1.97 m/hr

2.1 m/hr

2.07 m/hr

1.34 m/hr

1.42 m/hr

8-3/8” Impreg Runs - West Khulud Field, Oman

Drilled Interval

Well Depth (m)

4000

4200

4400

4600

4800

5000

5200