38 |

Oilfield Technology

June

2016

PLTs into the multiple legs of the wellbore was missing – until

now.

Theattractionofmultilaterals

Maximum reservoir drainage from minimal locations is what

lies behind the increased number of multilaterals that have

been drilled and completed in the last few decades. Multilateral

technology has evolved to offer not only the ability to drain

reservoirs more efficiently but also to potentially drain multiple

reservoirs simultaneously and with fewer surface locations.

Conventional wells were drilled vertically through the

reservoir, producing only from the vertical surface area uncovered.

In order to drain a large areal expanse, lots of wells were required.

As technology advanced, however, operators began to drill

deviated wells which by virtue of geometry alone increased the

exposure to the reservoir and (ideally) increased production

(Figure 1).

As technology continued to advance, horizontal wells

became much more prevalent; today dominating the total

number of wells drilled each year. This technique has had

tremendous impact across the globe, turning previously

uneconomical reservoirs into producers. Not only with the

highly documented shale oil and gas successes of the US, but

also in more classical lithology. A recent example from Norway

which demonstrates this is the Smorbukk South Extension

in the Asgard field. Originally discovered in 1985, its low

permeability prevented it from being completed. Recently,

however, long horizontal reservoir sections have been drilled

accessing the tight reservoirs. One of these oil and gas producers

was a multilateral with 17 060 ft of total reservoir exposure, a

significant advancement from the days of vertical drilling.

Technology infrequently develops in isolation and

improvements to horizontal drilling are no exception. Several

other enablers evolved in parallel; the abilities to ‘see’ better and

to ‘target’ better. This means that operators are now equipped

with the ability to identify reservoirs (or sections of reservoirs)

that were previously unidentified due to their size, characteristics

or proximity to geological artifacts that would hide them. Once

identified, the advances in ‘geosteeering,’ the ability to control the

bit during the drilling process, vastly increase the likelihood that

these targets can be accessed.

Hence the simultaneous development of multiple technologies

has led to the increased drilling and construction of horizontal,

multilateral wells. Many smaller reservoirs or sections which

were not economical to pursue individually due to their size or

location can now be combined into a single well. Or if they could

be accessed from a previously drilled well then they could be

brought onto production as part of the existing infrastructure.

These abilities have opened up a new mindset for well design as

technology is now available to find, target and access multiple

reservoirs or sections from a smaller number of well slots or pads,

reducing the cost of well construction while increasing production

and maximising reservoir drainage.

Datadrivesdecisions

Today’s society is largely influenced and driven by data. This is

also true when trying to optimise and increase total reservoir

drainage. Much time and effort is spent modelling and designing

the proper well placement in three dimensions for the best

possible solution. Production and subsequently total drainage

volume are impacted significantly by reservoir characteristics,

but even more so when trying to combine multiple reservoirs in

the same wellbore with the implementation of multilaterals.

1

It is not only well placement considerations that benefit

from correct data about the reservoir. Production data can help

reduce uncertainties in reserve estimates, sweep efficiencies

and in the case of multilaterals, pressure information which can

aid in detecting cross flow or preventing production below the

bubble point in the respective lateral.

2

The data about the reservoirs can be acquired from a

number of sources; seismic acquisition, during drilling or with

open hole logging but one of the most common ways to acquire

production data is via e-line conveyed PLTs. Fast, efficient and

sensor heavy, these tools can provide real time measurements

and surface read-out of fluid velocities, fluid types, borehole

pressure and temperature, formation capture cross section and

others. From these measurements a tremendous amount of

information about the reservoir and even the completion design

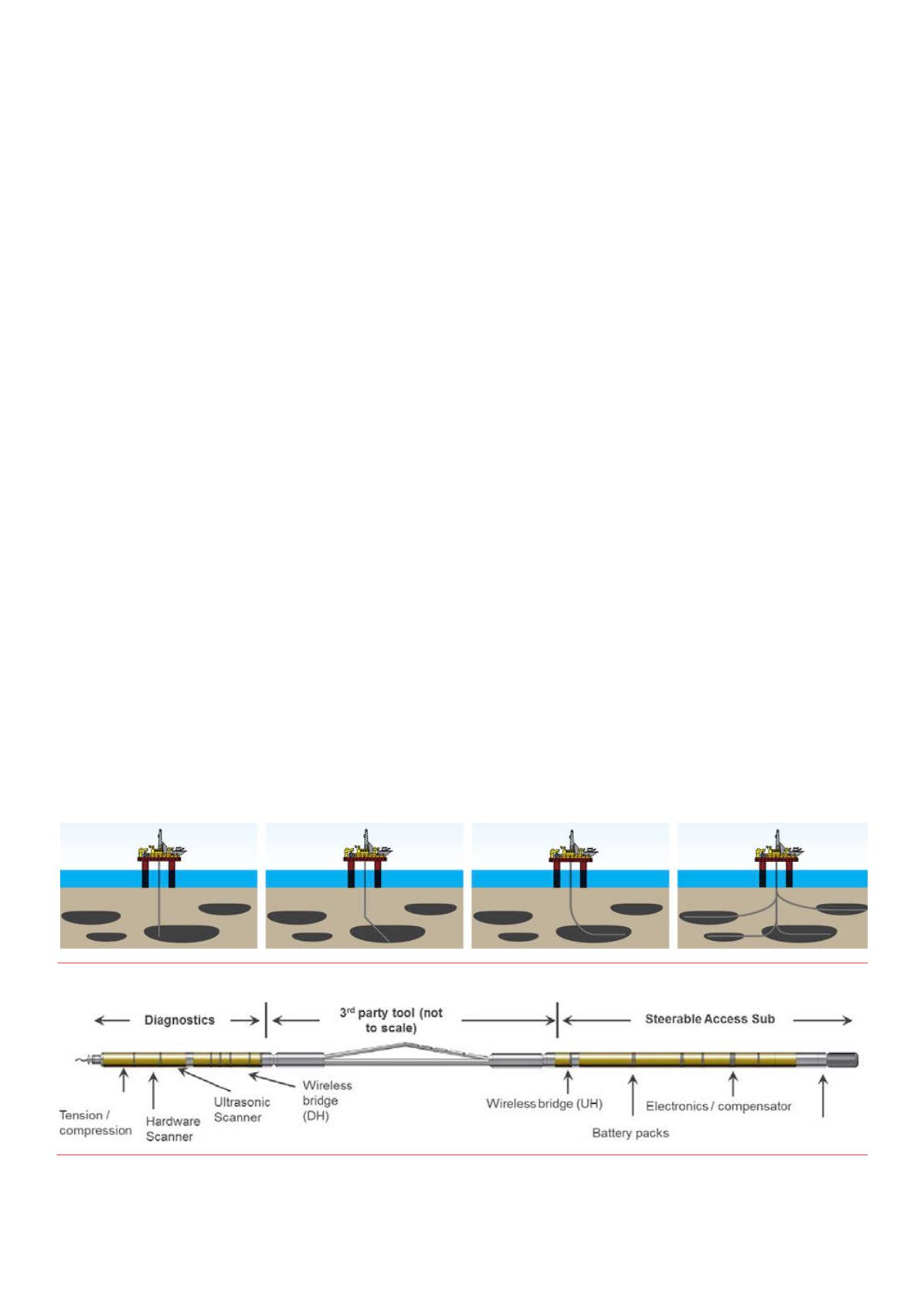

Figure 1.

Illustration of the evolution of increased reservoir contact.

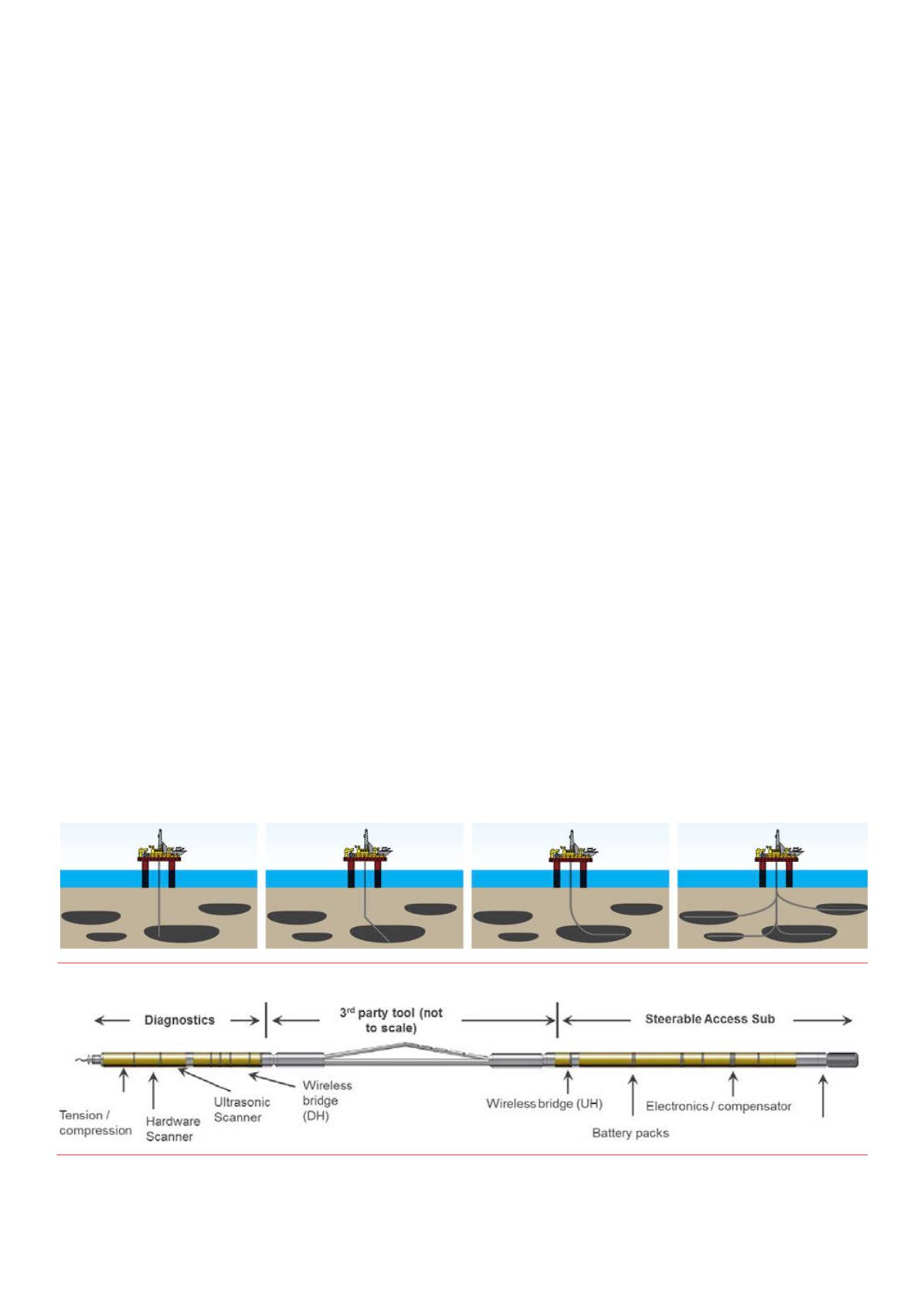

Figure 2.

Schematic of 2⅛ in. multilateral intervention tool.