48 |

Oilfield Technology

June

2016

entire Middle Bakken is 0.02 mD. Mercury injection capillary pressure

(MICP) data indicated that irreducible water saturation was between

30 - 40% for rock with and residual oil between 30 - 40%. Petrophysical

evaluation suggests that the Upper part of the Three Forks had oil

potential.

Average reservoir parameters for the upper Three Forks facies

are 8% porosity, 60% water saturation and permeability < 0.02 mD.

Irreducible water saturation was estimated as 45 - 55% for good and

poor quality rock respectively; residual oil is estimated at 40 - 55%

for good and poor quality rock respectively. In this area, the middle

and lower Three-Forks have higher water saturation, with very low

permeability streaks (< 0.007 mD).

Geomechanics

A key parameter in the iteration of various mechanical earth models

(MEMs) was the pore-pressure profiles. A pore pressure transition

region into the Lodgepole (Scallion formation), was created

where a linear pressure increase from salt water gradient up to

the estimated pore-pressure of the Upper Bakken Shale. For the

TRFK, a linear decrease of pore-pressure from over-pressured in

the Lower Bakken Shale to normal pressure was generated within the

first 100 ft. The pore pressure remained elevated across the pronghorn

and first two TRFK benches, and then reduced back to a salt-water

gradient for the remaining TRFK benches.

Fracturemodelling -MiddleBakken

For the Middle Bakken: Micro-seismic and

the diagnostic fluid injection test (DFIT) data

together with interference information from 355

offset fractures with 47 communication events,

constrained the expected geometry height growth

and an expected fracture length, in both the MB

and TRFK. For the Three Forks: micro-seismic data

and interference information from 134 fractures

with 28 communication events constrained an

expected geometry height above and below the

TRFK, and a minimum expected fracture length in

the MB and the TRFK.

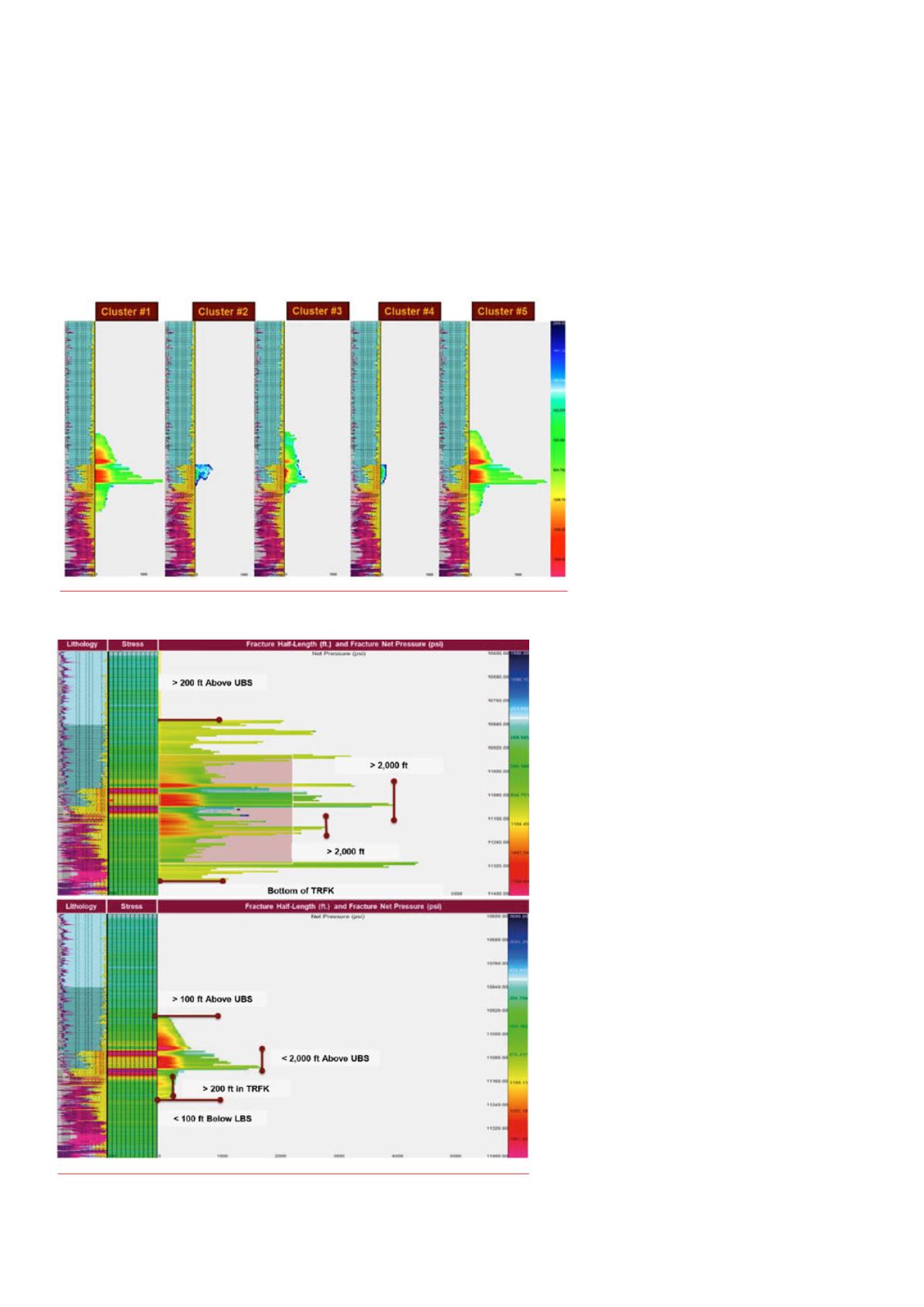

Analysis on the Bakken wells in the study

area indicated high (> 1500 psi) net-pressures

and low breakdowns. This implies that a

plug-and-perf (PnP) completion methodology

could yield success by enabling multiple

perforating clusters (within a stage) to breakdown,

especially when high pump rates (typical of slickwaters)

are utilised (Figure 1). When parent well sliding-sleeve (SS)

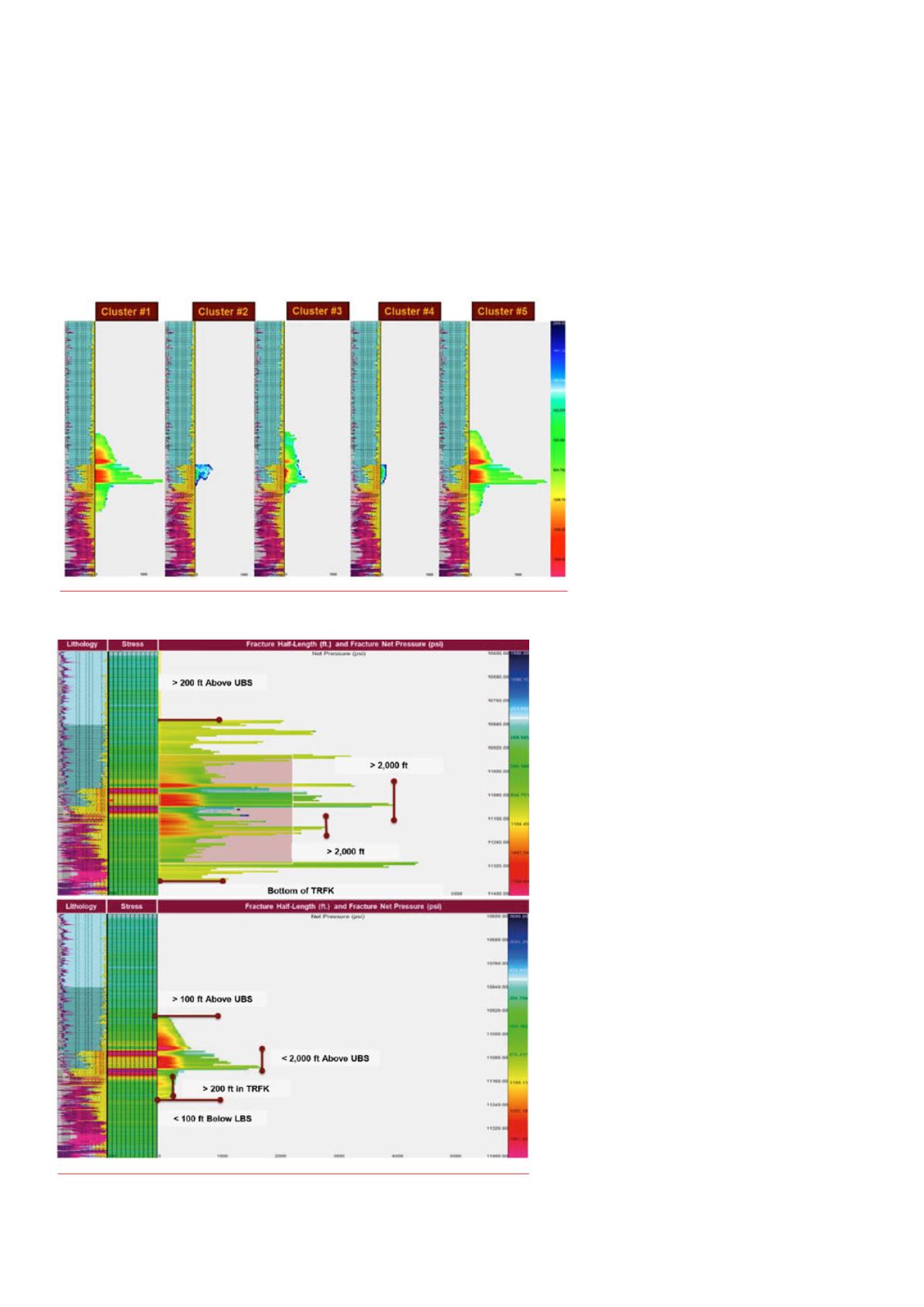

treatments were modelled (Figure 2), a large single

dominant fracture was observed (via fracture modelling

and production modelling). When parent well PnP

treatments were modelled (in the same area), propagation

of multiple fractures was confirmed by both fracture and

production modelling. Fracture modelling indicated that

two dominant fractures were propagating.

Productionmodelling

For the Bakken model, the upper and lower shale were

modelled, together with the Middle Bakken. Daily

bottom-hole pressures (BHP) were computed and

calibrated to BHP gauge data on offset wells to select the

appropriate flow – correlation. Compaction curves were

generated from core data and utilised to model fracture

conductivity and permeability degradation. The SS Middle

Bakken well has a permeability of >0.01 mD, maximum

fracture half-length of 250 ft and a dimensionless fracture

conductivity that reduces from seven to four. Flowing

bottom-hole gauge data was used to constrain the history

match (Figure 3). Compaction curves from core and

proppant were utilised to model degradation of proppant

conductivity and rock compaction (permeability/porosity

reduction). An ‘additional damage’ factor (using

compaction curves) had to be added after two years of

production to match the fluid level measurements. This

damage increased with time. The initial hypothesis was

proppant crushing (since effective stresses were close to

6000 psi – crushing pressure of sand).

Figure 2.

Comparison of sliding-sleeve (single fracture) andplug-and-perf geometries

(dominant cluster of three).

Figure 1.

Typical fracture geometry variation expected ina stage.