50 |

Oilfield Technology

June

2016

standing logging tools only, multiple measurements and models must

be created with the aim of reducing uncertainty.

Petrophysics

Petrophysical evaluation indicates that the average of porosity and

water saturation were greater than 9% and less than 18% respectively.

The petrophysical model results show that the permeability ranged

from 100 – 900 nD.

Geomechanics

The Ben Eaton stress model with a variable anisotropic Biot model was

utilised using calibration from core. An iterative approach engaging

fracture modelling, constrained by log responses (that imply possible

pore pressure transitions) resulted in an estimation of pore pressure

gradient from the Austin Chalk into the Buda.

Fractureandproductionmodelling

In the Eagle Ford dataset, since little in-fill drilling has occurred; limited

interference or micro-seismic data exists. A similar workflow utilised in

the Bakken Three Forks was utilised to understand fracture geometry

and constrain production historymatch parameters. High net-pressures

(>1200 psi during treatment and > 500 psi in the DFIT) in the Eagle Ford

enabled the breakdown of multiple clusters. Modelling indicates that

some optimisation opportunities still exist within themulti-cluster

fracturing scenarios since only 30 - 50%of the fractures within a stage

can create dominant fractures. Modelling indicates that if a lateral

porpoises across ‘critical’ stress units, the propagation and connectivity

within the reservoir changes significantly. Production historymatches

honoured the relative change in fracture half-lengths within a stage due

to limited entry or stress shadowing. Productive fracture half-lengths

varied from50 - 200 ft and permeability ranges from70 - 500 nD. More

than two years of production history was matched on two parent wells.

The importance of layering effects causing pinching and

preferential propagation in most unconventional plays are forcing

operators to realise that draining a thick reservoir column with multiple

laterals can improve production performance significantly.

EagleFordsystemin-fillwell/depletionmodelling

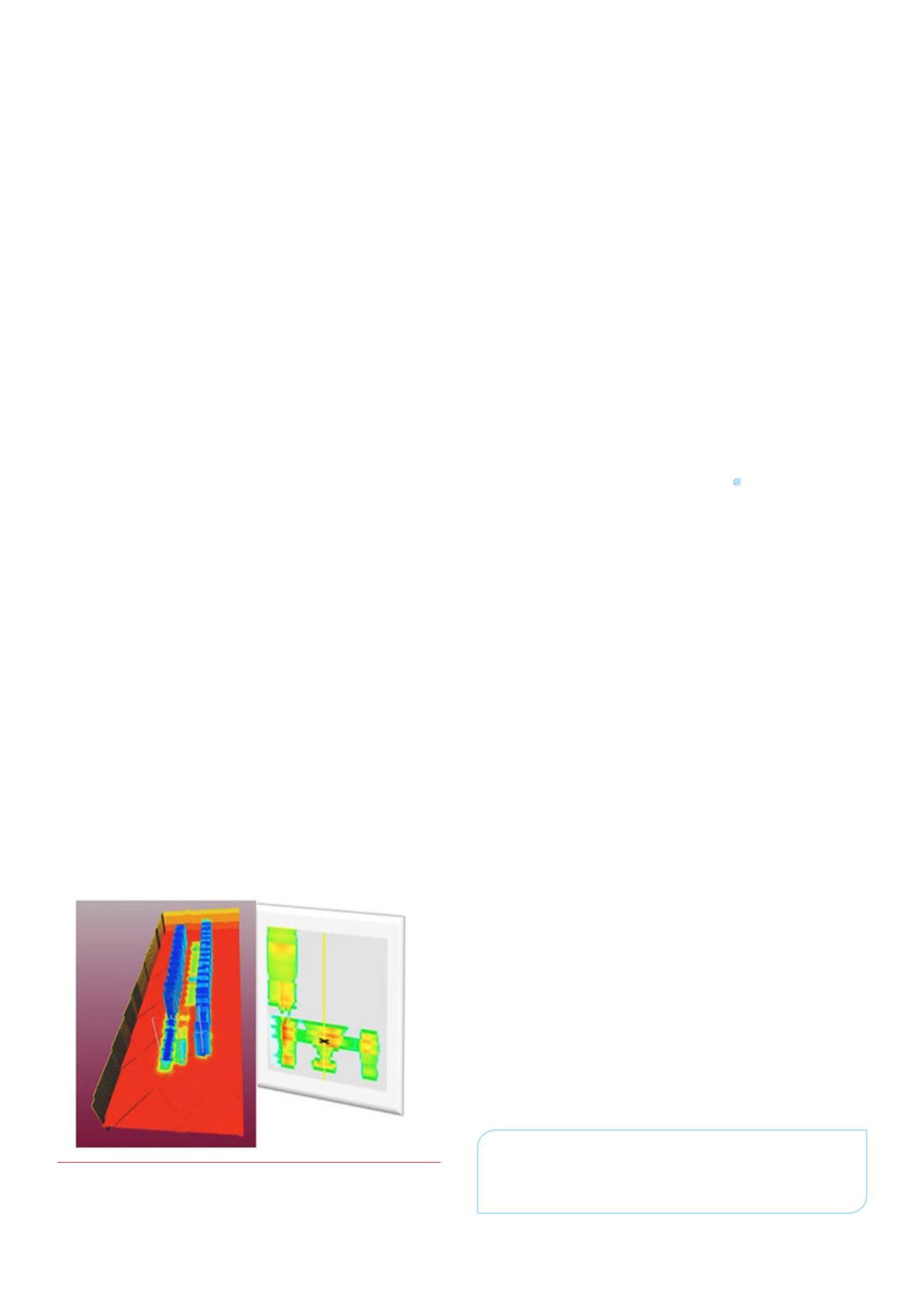

Figures 3 and 4 demonstrate the early impact of in-fill drilling

and interference in the Bakken and Woodford. Overestimation of

vertical connectivity across the entire column can result in the

under-estimation of the depletion sink.

Once production history matching was performed on the parent

well, the new stress state was re-computed to model the impact of

fracture propagation between two parent wells. Fracture modelling

indicates that production from the upper benches can create improved

containment with similar effectiveness using smaller designs and

create weak points that result in height growth that would otherwise

not be observed under virgin conditions. Based on the forward models,

in-fill treatments were designed to minimise asymmetrical effects and

direct interference with the offset wells. Figure 5 shows the impact of

a larger design-optimised design not shown. Preliminary production

results are encouraging and continued monitoring, testing and

evaluation will take place.

Conclusions

This study demonstrated that parent well modelling was critical to

understanding which wells are within the region of interference. The

success of the in-fill well completion design is determined by the ability

to characterise the current production system in order to understand

the extent of depletion. Modelling was utilised to understand the

changes required in operational activities when performing in-fill

development. The observation of the potential challenges and

re-design of the completion program has resulted in significant

success. The introduction of a model based approach to improve

decision making will reduce the cycle time between the initial wells

drilled and the optimal development strategy.

Acknowledgements

SM Energy: Nathan Nieswiadomy, Brent Bundy, Sarah Edwards.

Sanjel Corporation: Rafif Rifia, Kristina Kublik, Santhosh Narasimhan,

James Gray, Olubiyi Olaoye, Hamza Shaikh.

References

1.

US Energy Information Administration.

_

gas.pdf, (April 13, 2015).

2.

Cherian, B.V, Nichols, C.M., Panjaitan, M.L., Krishnamurthy, J.K., Sitchler,

J., ‘Asset Development Drivers in the Bakken and Three Forks’, SPE 163855;

SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA,

(4 - 6 February, 2013).

3.

Mukherjee, H., Poe Jr., B.D. Heidt, J.H., Watson, T.B., and Baree, R.D., ‘Effect

of Pressure Depletion on Fracture Geometry Evolution and Production

Performance’, SPE 65064, SPE Annual Technical Conference and Exhibition,

Dallas, Texas, USA, (22 - 25 September, 1995).

4.

Ajani, A., Kelkar, M., The University of Tulsa, ‘Interference study in Shale Plays’,

SPE 151045, SPE Hydraulic Fracturing Technology Conference, the Woodlands,

Texas, (6 - 8 February, 2012).

5.

Waters, G.A., Dean, B.K., Downie, R.C., Kerrihard, K.J., Austbo, L., McPherson, B,

‘Simultaneous Hydraulic Fracturing of Adjacent Horizontal Wells in the

Woodford Shale’, SPE 119635; SPE Hydraulic Fracturing Technology Conference,

The Woodlands, Texas, (19 - 21 January, 2014).

6.

Wheaton, B., Miskimins, J., Wood, D., Lowe, T., Barree R., ‘Integration of

Distributed Temperature and Distributed Acoustic Survey Results with

Hydraulic Fracture Modelling: A Case Study in the Woodford Shale’, URTeC

1922140. SPE/AAPG/SEG Unconventional Resources Technology Conference,

Denver, Colorado, USA, (25 - 27 August, 2014).

7.

Lalehrokh, F., and Bouma, J., Talizman Energy USA, ‘Well Spacing in Eagle

Ford’, SPE 171640, SPE/CSUR Unconventional Resources Conference – Canada,

Calgary, Alberta, Canada, (30 September - 2 October).

8.

Ganpule, S., Srinivasan, K., Izykowski, T., Luneau, L., and Gomez, E., ‘Impact

of Geomechanics on Well Completion and Asset Development in the Bakken

Formation’, SPE-173329. SPE Hydraulic Fracturing Technology Conference, the

Woodlands, Texas, (3 - 5 February, 2015).

9.

Heller, R., Vermylen, J., and Zoback, M., ‘Experimental investigation of matrix

permeability of gas shales’, AAPG Bulletin, v. 98, no. 5 (May, 2014), pp. 975 - 995.

10. Narasimhan, S., McCleary, M., Fluckiger, S., Gray, J., Cherian, B., Shaikh, H.,

‘Using the wrong method to estimate stresses from depletion causes significant

errors in predicting wellbore integrity and fracture geometry’, SPE 173310,

SPE Eastern Regional Meeting held in Morgantown, West Virginia, USA,

(13 - 15 October, 2015).

Figure 5.

Example of depletionprofile fromassymetric propagationand

fracture geometry as a result of the in-fill drillingbetween two parent

wells in the Eagle Ford.

Note

To read this article online, along with the full reference list, please

visit: