54 |

Oilfield Technology

June

2016

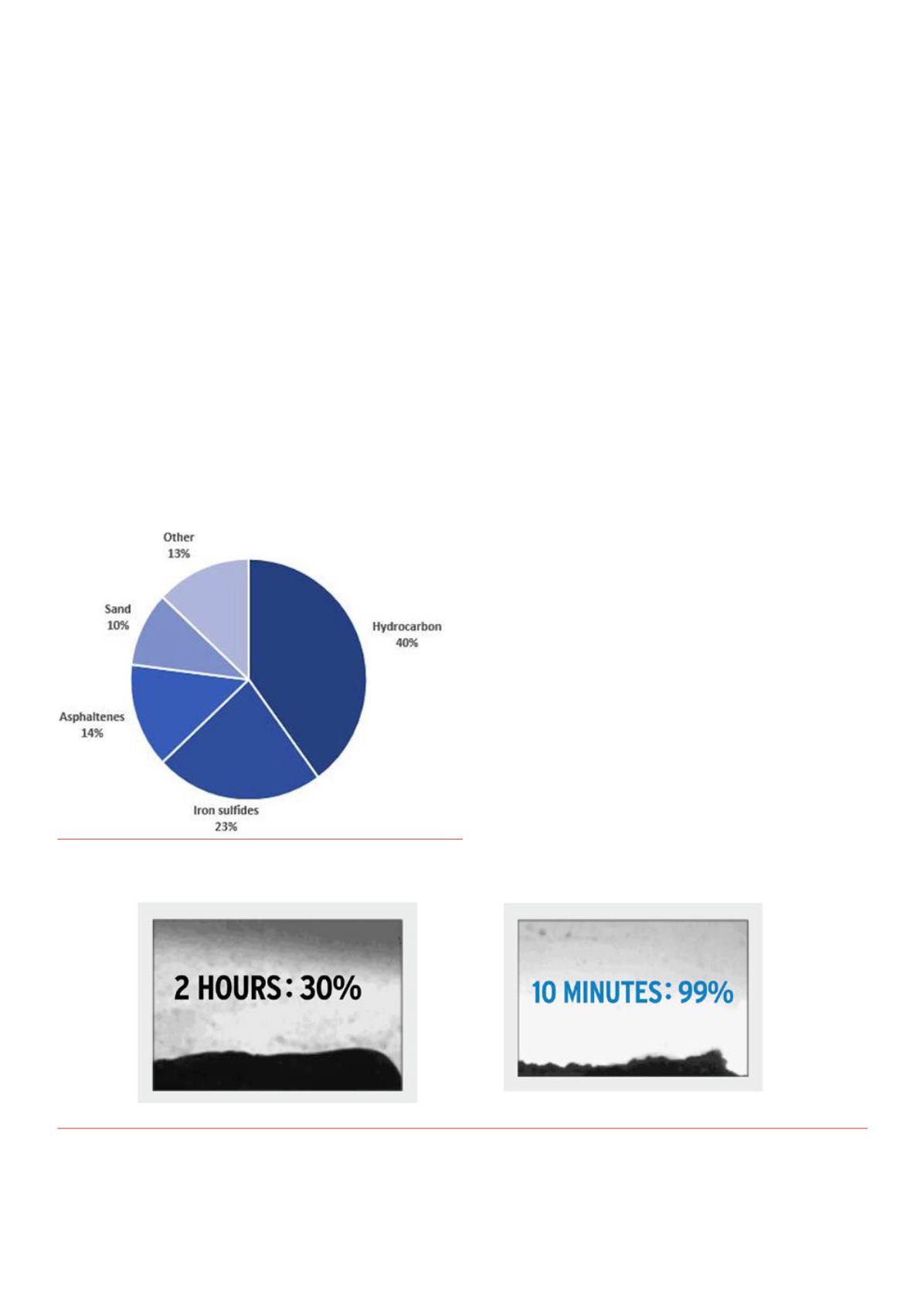

The main components are hydrocarbons, iron sulfides, asphaltenes,

sand, and clays (The relative ratio of each component will be system

specific). This combination results in an oily sludge that blocks

pore throats and coats the injection system. This oily sludge can

also provide an environment conducive to under-deposit corrosion

resulting in accelerated pipe failures.

Typical corrosion prevention involves injecting corrosion

inhibitors into production fluids and can be an extremely

cost-effective means of mitigating corrosion in carbon steel pipelines.

Unfortunately, the inhibitors are worthless if they cannot reach the

pipe wall. This is because this oily sludge forms a tenacious barrier

that cannot be penetrated by most corrosion inhibitors. It acts

as a parasitic surface adsorbing the inhibitor from the bulk liquid

phase. Consequently, these deposits can create significant integrity

management challenges.

Theneedforadifferent solution

The importance of keeping production equipment clean and the

difficulty in dealing with this oily sludge is clear. While the thickness

of oily sludge in a pipeline may range from only a few millimetres to

several centimetres or more, the outcome is the same: the sludge

may adsorb significant quantities of corrosion inhibitor, preventing

the inhibitor from reaching the pipe wall.

Thus the sludge deposits have to be physically removed from the

pipeline, typically through maintenance pigging operations. However,

in many fields with an older infrastructure, pig launchers and receivers

may not be installed, and even if they are, the pipe configuration

may have changed such that there is pipe of varying diameter along

the same line. It is often very difficult, if not impossible, to pig a line

like that. Pigging operations can also result in process upsets, lost

production, significant Opex costs, and EH&S challenges.

Recognising the importance of tackling this problemmore

than 10 years ago, Nalco Champion began a thorough research

effort, aimed at understanding the factors involved in successfully

removing oily sludge by chemical means, and then developing a

formulation that could effectively remove this sludge while also

mitigating aggressive corrosion. The company’s field operators in

North America dealing with the problem of corrosion under sludge

provided samples to staff scientists to assist with the research effort.

Compositional analysis revealed that the majority (40%) of the sludge

was hydrocarbon, which was essentially the ‘glue’ holding the solids

in the sludge together (Figure 1).

Researchefforts result inamulti-functional

technology

By focusing on a way to desorb or remove the hydrocarbon ‘glue’, the

remaining solids should be carried off the surface as well, allowing the

corrosion inhibitor to reach the pipe wall. Thus after extensive research

and testing, a multi-functional product was developed that was seen

to be significantly superior to conventional corrosion inhibitors at

removing oily deposits. The removed oil is emulsified as fine droplets

in the circulating brine phase. Since the oil is the ‘glue’ holding the

solid components of the deposit together, once it is removed, the

solids can also readily be removed and are held in suspension in the

brine. Reducing this obstruction enabled a significant increase in water

injectivity and consequently oil production.

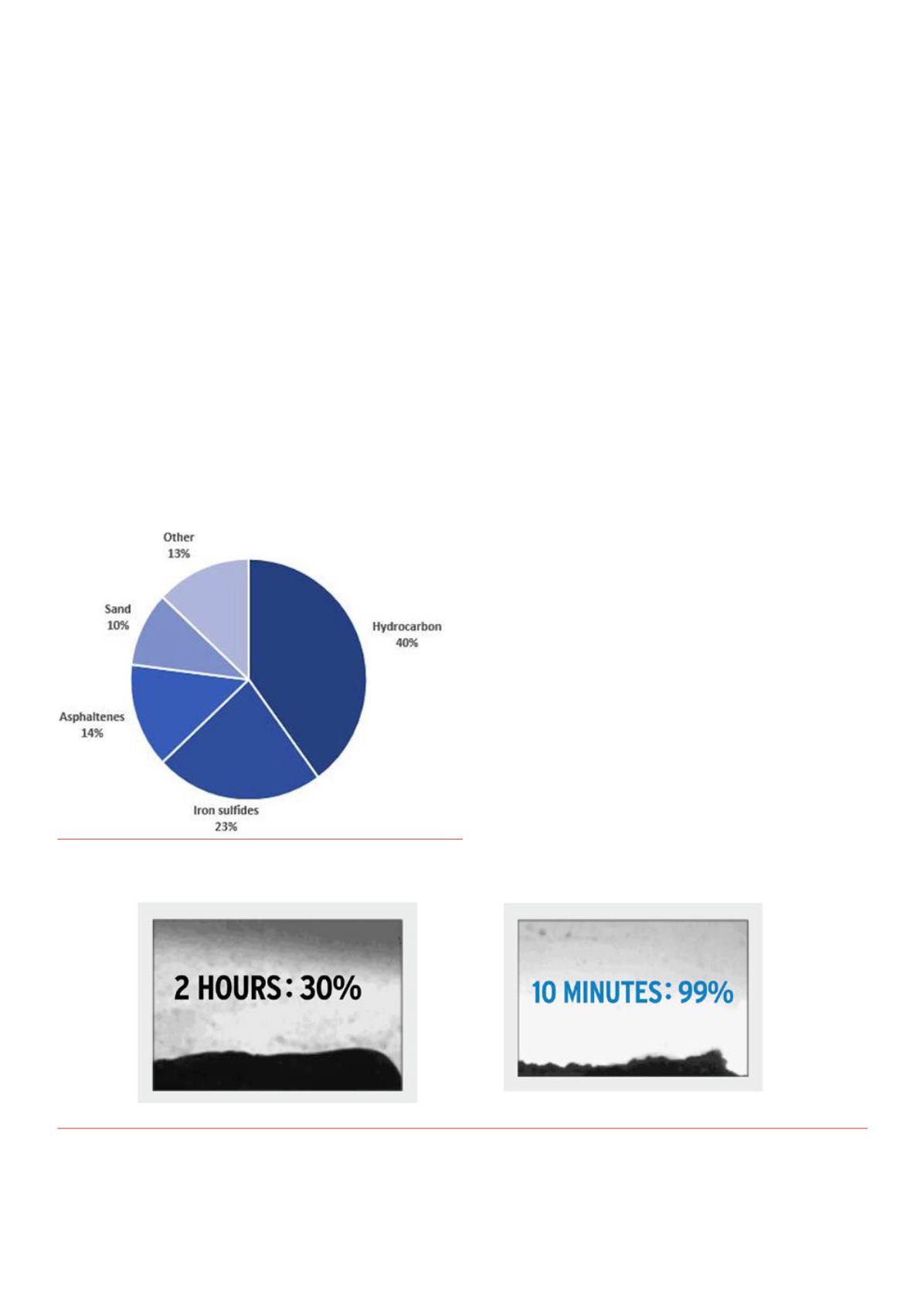

In an initial laboratory test, at a dosage of 80 ppm, 99% of the

oily sludge was removed within 10 minutes (Figure 2). The corrosion

inhibition performance was further evaluated in a series of laboratory

tests. In virtually all studies performed, the new product was seen

to exhibit a performance superior to an established ‘best in class’

inhibitor. Even under shear stresses of 800 Pa, the product exhibited

95% protection at a dosage of 25 ppm. This performance was also

validated in field evaluations.

This product was named Clean n Cor®. When introduced into a

water injection system, the product is designed to clean away oily

Figure 1.

Compositional analysis of field sample of oily sludge.

Figure 2.

Photos of initial NalcoChampion newproduct lab test results. The image on the left shows that the best in-class inhibitor removed only 30%

of oily buildupafter two hours. The image on the right shows that after 10minutes, the Clean nCor technology removed 99%of the buildupdosage

at 80 ppm. Inboth lowand high shear tests. The new technology performedat least aswell as the best in-class product, providinggreater than 95%

protection efficiency at lowdosages between 5 and 25 ppm.